Drive Efficiency in EV Manufacturing with Odoo ERP

- August 8, 2024

- Posted by: Vasanth Anantharaman

- Categories: Blog, Odoo

The electric vehicle (EV) industry is rapidly expanding, driven by the global push for sustainable and eco-friendly transportation. According to the International Energy Agency (IEA), electric cars accounted for 18 percent of total cars sold in 2023, up from 14 percent in 2022. However, EV manufacturing presents a unique set of challenges that differentiate it from traditional vehicle production. The integration of advanced technology, the complexity of components like batteries and electric engines, the extensive use of electronics to monitor performance of the vehicle, and the stringent quality standards are just a few of the hurdles that manufacturers must overcome to stay competitive.

Unlike traditional vehicles, EVs require meticulous attention to detail during production. Battery assembly, electric engine production, and vehicle integration are intricate processes that demand precision and coordination. Each of these stages is critical, and any inefficiency or bottleneck can lead to significant delays and increased costs. This complexity necessitates a robust and integrated system to manage the various aspects of EV production efficiently.

Odoo ERP recognizes these challenges and has become a powerful solution to streamline EV manufacturing processes. This comprehensive ERP suite is designed to address the specific needs of EV manufacturers, providing tools that effectively manage everything from production planning and inventory management to quality control and real-time data analysis.

With Odoo ERP, EV manufacturers can create and manage detailed bills of materials (BOMs), schedule work orders, optimize resource allocation, and forecast production needs accurately. This level of control and insight helps reduce production time, improve quality, and lower costs. Odoo ERP’s capabilities in managing complex inventories, tracking components, and ensuring quality control make it a valuable tool for the EV industry.

In this blog post, we will delve into the intricacies of the EV production process, highlight potential bottlenecks, and demonstrate how Odoo ERP can address these challenges effectively. Read on as we uncover the benefits of integrating Odoo ERP into your EV manufacturing operations.

Key Stages in the EV Production Process

Electric vehicle (EV) production involves several stages, each requiring precise coordination and execution to ensure the final product meets standards of quality and performance. Let’s break down the four key stages in the EV production process:

- Battery Assembly The battery is the heart of an EV, powering all its operations. According to BloombergNEF, battery pack prices have been falling year on year in the last 10 years, making them more accessible but also more complex to produce efficiently. Battery assembly involves creating battery packs from individual cells, ensuring they are properly connected and housed to provide optimal performance and safety. Given the importance of batteries, any inefficiency in this stage can significantly impact the overall production timeline and vehicle performance.

- Electric Motor Production The electric engine is crucial for the propulsion of an EV. Producing these motors involves winding coils, assembling components, and performing rigorous testing to ensure they meet required specifications. This stage is highly technical and demands precise manufacturing processes to ensure reliability and efficiency.

- Vehicle Assembly This stage involves integrating various components, such as the battery, electric motor, and dozens of electronic systems, into the vehicle chassis. The assembly process must be meticulously planned and executed to ensure all components fit together seamlessly and the vehicle operates correctly. Coordination between different production teams is vital to avoid delays and ensure a smooth assembly process.

- Quality Control Ensuring the quality and safety of EVs is paramount. Quality control checks are performed at various stages of production to identify and rectify any defects or issues. This involves testing individual components, such as batteries, motors, and electronic systems and performing comprehensive tests on the assembled vehicle. Effective quality control processes help maintain high standards and build customer trust in the final product.

Despite meticulous planning, inefficiencies can arise in EV manufacturing. For example, the complexity of battery technology and the need for extensive safety testing can lead to delays. Additionally, coordinating the supply chain for specialized components, such as electric motors and advanced electronics, can pose challenges.

Odoo ERP can address these challenges by providing a unified platform for managing the entire production process. With features like real-time tracking, detailed production planning, and integrated quality control, Odoo ERP helps identify and mitigate bottlenecks, ensuring a more streamlined and efficient production process.

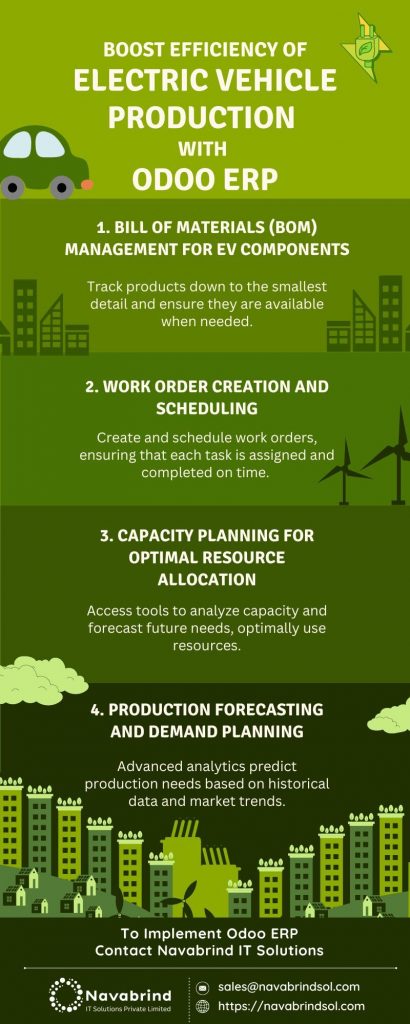

Role of Odoo ERP in EV Production Planning

Leverage Odoo’s manufacturing module to streamline processes, and ensure that every stage of production in the complex world of EV manufacturing, is well-coordinated and efficient.

- Bill of Materials (BOM) Management for EV Components: Odoo ERP allows manufacturers to create and manage detailed BOMs, which are essential for tracking all the components required for EV production. This feature ensures that all parts, from individual battery cells to complete motor assemblies, are accounted for and available when needed.

- Work Order Creation and Scheduling: Efficient scheduling is critical to avoid production delays. Odoo ERP facilitates the creation and scheduling of work orders, ensuring that each task is assigned appropriately and completed on time.

- Capacity Planning for Optimal Resource Allocation: Capacity planning is vital to optimize the use of resources such as labor, machinery, and materials. Odoo ERP provides tools to analyze current capacity and forecast future needs, allowing manufacturers to avoid overloading or underutilizing resources.

- Production Forecasting and Demand Planning: Accurate forecasting and demand planning are essential to align production with market demand. According to a Gartner study, improved forecasting can lead to a 10% to 20% reduction in inventory costs. Odoo ERP’s advanced analytics tools help manufacturers predict production needs based on historical data and market trends. This ensures production is optimized to meet demand without overproducing or creating shortages.

Managing EV Component Inventory

Efficient inventory management is a cornerstone of successful EV manufacturing. Odoo ERP streamlines this critical aspect.

- Tracking Different Types of Batteries, Motors, and Other Components: Odoo ERP enables manufacturers to track components, ensuring that the right parts are always available. This includes managing inventory for different types of batteries, electric motors, and other specialized components crucial for EV production.

- Implementing Lot and Serial Number Tracking for Quality Control: Odoo ERP’s lot and serial number tracking features ensure that each component can be traced back to its origin, facilitating thorough quality checks and ensuring that any defects can be quickly identified and addressed.

- Warehouse Management and Stock Optimization: According to the Warehousing Education and Research Council, implementing warehouse management systems can improve order accuracy upward of 50%. Odoo ERP provides tools to manage warehouse operations, optimize stock levels, and streamline the movement of goods.

- Supplier Management and Procurement: Managing relationships with suppliers and ensuring timely procurement of components are critical to avoid production delays. Odoo ERP helps manufacturers manage supplier interactions, track orders, and ensure that components are procured on time and within budget.

Ensuring Quality Control in EV Production

Quality control is paramount in the EV industry, where safety and performance are critical. Navabrind IT Solutions utilizes Odoo ERP to enhance quality control measures in EV manufacturing.

- Quality Control Checklists and Inspection Processes: Odoo ERP allows manufacturers to create detailed quality control checklists and implement systematic inspection processes. These checklists ensure that every component and final product meets stringent quality standards.

- Non-Conformance Reporting and Corrective Actions: According to the American Society for Quality, companies that invest in quality control can see a return on investment (ROI) of up to 60%. Odoo ERP provides tools for non-conformance reporting, allowing manufacturers to document issues and implement corrective actions promptly.

- Traceability of Components and Products: Odoo ERP’s tracking capabilities ensure that every component can be traced through the production process, enabling quick identification of issues and ensuring that quality standards are maintained.

- Quality Analytics and Reporting: Analyzing quality data helps manufacturers identify trends and areas for improvement. Odoo ERP’s analytics tools provide insights into quality performance, helping manufacturers make data-driven decisions to enhance their production processes.

Optimizing EV Production with Real-Time Data

Real-time data in EV manufacturing provides insights that drive efficiency and quality.

- Production Performance Metrics: Monitoring production performance in real-time helps identify inefficiencies. Odoo ERP provides detailed metrics on production performance, allowing manufacturers to make adjustments and optimize processes.

- Inventory Levels and Turnover: Real-time tracking of inventory levels and turnover rates ensures that manufacturers have the components they need when they need them. Odoo ERP’s inventory management tools provide up-to-the-minute data on stock levels, helping prevent shortages and overstocking.

- Quality Control Data: Real-time quality control data enables manufacturers to address issues. Odoo ERP’s quality control tools provide instant feedback on production quality, allowing manufacturers to maintain high standards consistently.

- Predictive Analytics for Potential Issues: According to an article published in the World Economic Forum, predictive maintenance can reduce breakdowns by 70%. Odoo ERP uses historical data and trends to forecast potential problems, enabling manufacturers to take proactive measures and avoid disruptions.

Future Trends in EV Manufacturing and ERP Systems

As the EV industry continues to evolve, several trends are expected to shape the manufacturing landscape. Integrating advanced ERP systems like Odoo v17 will be crucial in navigating these changes and maintaining a competitive edge.

- Increased Automation and Robotics: The future of EV manufacturing will see a significant rise in automation and robotics. Advanced ERP systems will play a role in managing and optimizing automated processes, ensuring seamless integration between robotics and other production activities. According to a report by McKinsey, automation could reduce manufacturing costs by up to 20%.

- Data-Driven Manufacturing: Odoo ERP’s real-time data analytics tools will be essential in harnessing this data to improve production efficiency, predict maintenance needs, and reduce downtime. Gartner predicts that by 2025, data-driven businesses will see a 20% increase in operational efficiency.

- Sustainable Manufacturing Practices: Sustainability will be a key focus, with an emphasis on reducing carbon footprints and implementing eco-friendly manufacturing practices. Odoo ERP can help track and manage resources efficiently, minimizing waste and optimizing energy usage. The World Economic Forum highlights that sustainable practices can lead to a 30% reduction in energy costs.

- Customization and Flexibility: Consumer demand for customized EVs will drive the need for flexible manufacturing processes. ERP systems like Odoo will facilitate the customization of production workflows to meet specific consumer requirements, enhancing customer satisfaction and market competitiveness.

- Integration with IoT and AI: The integration of the IoT and AI will transform EV manufacturing. Odoo ERP’s compatibility with IoT devices will enable real-time monitoring and control of manufacturing processes, while AI can optimize production schedules and improve quality control.

In conclusion, the electric vehicle (EV) industry faces unique production challenges that necessitate innovative solutions. Odoo ERP stands out as a critical tool, streamlining processes from battery assembly to vehicle integration with features like detailed BOMs, work order scheduling, and real-time data analytics. This comprehensive system helps reduce production time, improve quality, and lower costs while managing complex inventories and ensuring rigorous quality control. As EV manufacturing evolves with trends in automation, data-driven practices, and IoT integration, Navabrind IT Solutions’ expertise in Odoo ERP implementation provides EV companies with the support needed to enhance efficiency, productivity, and sustainable practices, ultimately advancing the future of eco-friendly transportation.

Let’s connect to start a conversation on how Navabrind IT Solutions can help you. Drop us a note at [email protected] to schedule a free consultation.

Schedule a conversation with us now!

Related Articles

-

Post

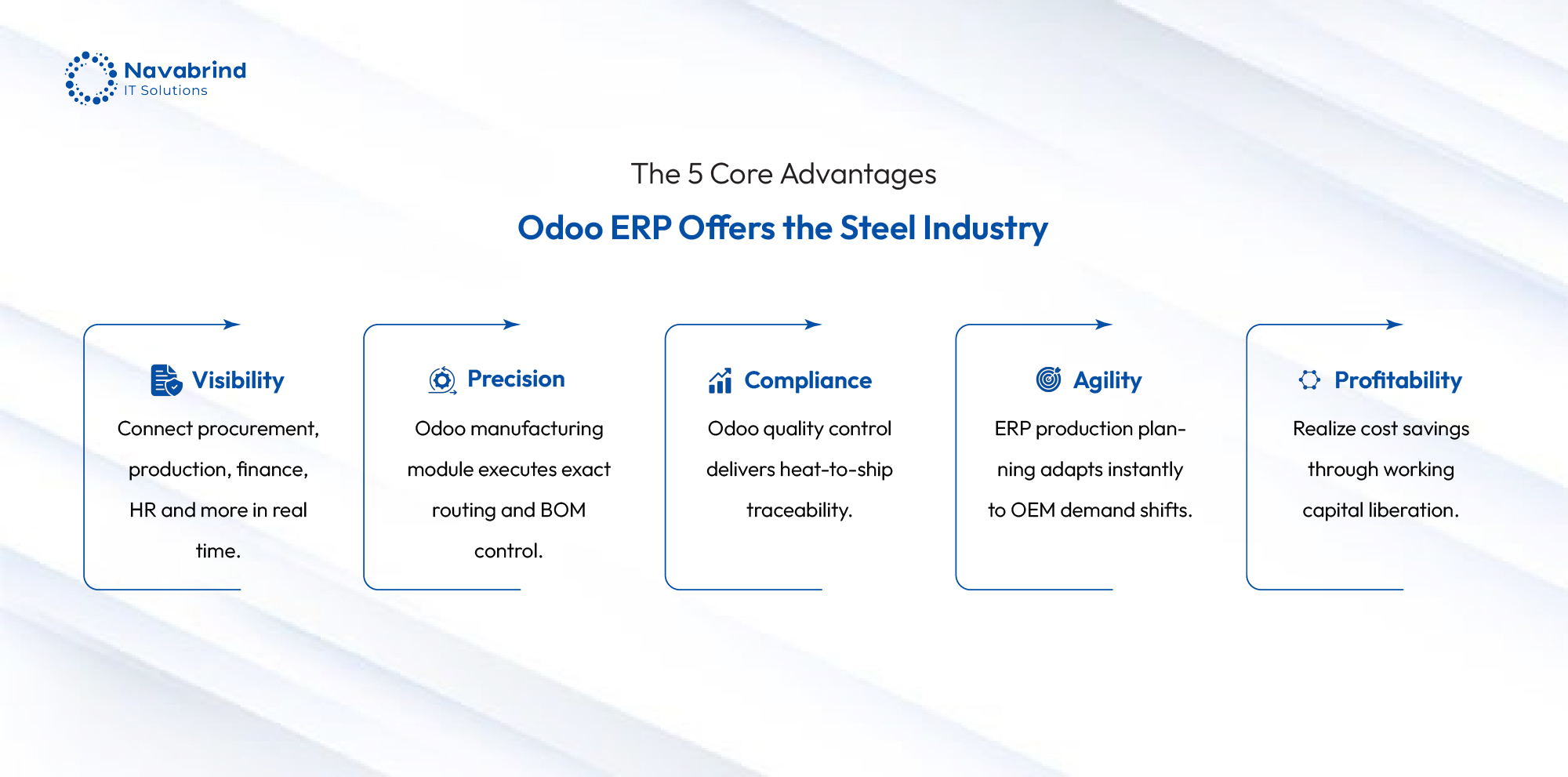

How Odoo ERP Drives Efficiency in the Steel Industry

How Odoo ERP Drives Efficiency in the Steel Industry February 18, 2026 Posted by: Tony Categories: Blog, Odoo No Comments The High-Stakes Race of Auto Parts Manufacturing Your OEM demands a production schedule shift, but procurement can’t confirm steel availability. The sales team lacks real-time inventory data for a quote and your shop floor operates -

Post

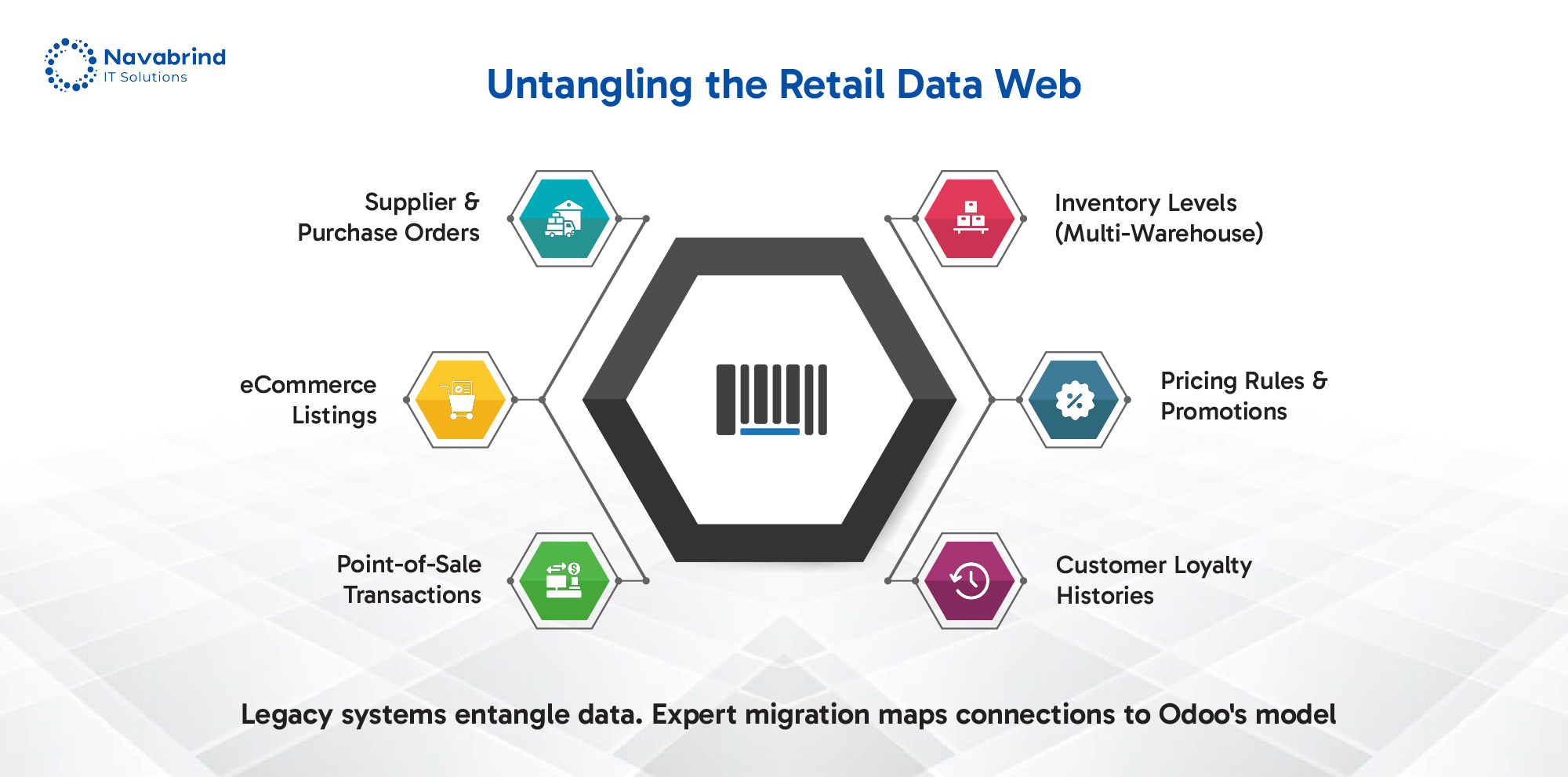

Odoo Database Migration Guide: From Homegrown Retail ERP to Odoo ERP Without Downtime

Odoo Database Migration Guide: From Homegrown Retail ERP to Odoo ERP Without Downtime February 18, 2026 Posted by: Tony Category: Uncategorized No Comments The Need for Smooth Odoo Database Migration If your outdated software, disparate applications, and an unsupported ERP begin to hinder work, you are no longer dealing with a minor technical issue, but -

Post

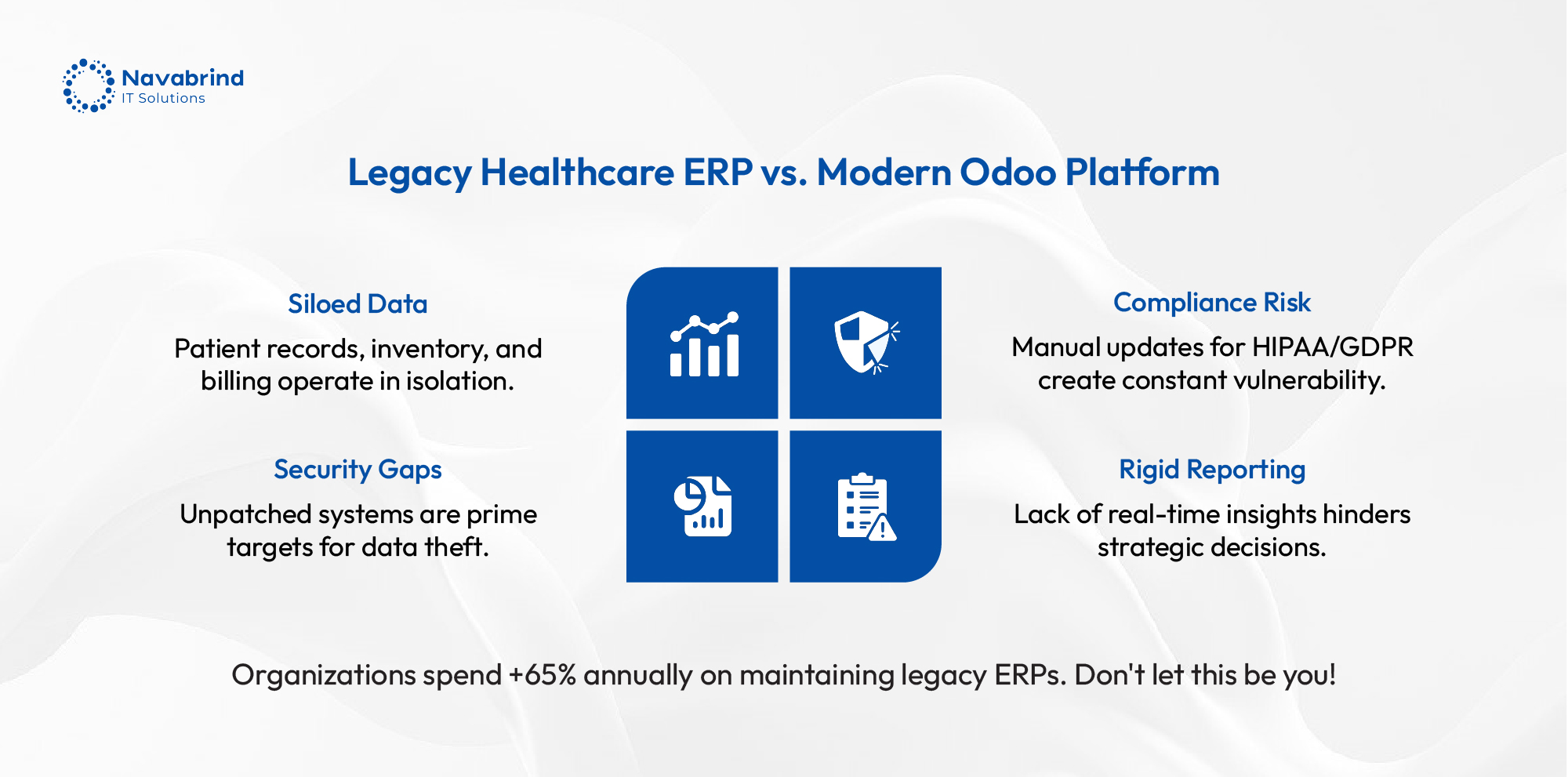

From Legacy Healthcare ERP to Odoo ERP: Why You Need Expert Odoo Migration Help

From Legacy Healthcare ERP to Odoo ERP: Why You Need Expert Odoo Migration Help February 11, 2026 Posted by: Tony Category: Uncategorized No Comments Why Healthcare Organizations Need Odoo ERP Migration Legacy healthcare ERP systems create barriers to efficiency. They are expensive to maintain, and struggle to integrate tools. This disconnect impacts patient care coordination,

How can we help you?

Get in touch with a solutions consultant that can share best practices and help solve specific challenges.