Streamline Your Manufacturing Operations with Odoo ERP

- November 15, 2024

- Posted by: Tony

- Categories: Blog, Odoo

Manufacturing is one of the largest and most complex sectors in the world. It consists of heavily interconnected supply chains that can span multiple countries. Components in a manufacturing plant are sometimes sourced globally and require effective coordination between suppliers, manufacturers, and distributors before they reach a production plant thousands of miles away.

The pandemic, geopolitical shifts, and the introduction of Industry 4.0 technologies such as IoT, AI, robotics, and automation have created major shifts in the manufacturing sector. Today, smart factories enable real-time monitoring, predictive maintenance, and data-driven production. These shifts also support sustainability by optimizing resource use.

Manufacturing companies must comply with complex and varying regulations across regions, covering safety standards, labor laws, environmental impact, and product quality. Navigating these compliance requirements adds to the complexity that manufacturing companies must plan for.

This is where Odoo for Manufacturing offers a comprehensive ERP for factory management. Odoo’s Manufacturing module includes powerful features to coordinate processes in inventory, manufacturing, product lifecycle management (PLM), purchase, maintenance, quality, and more.

In this blog post, we will explore how the Odoo manufacturing module simplifies operations, enhances productivity, and meets the needs of businesses ranging from small manufacturers to large enterprises.

Does your business need an ERP for factory management?

Managing a factory is complex—multiple teams, machines, departments, processes of varying importance, hardware, and software must work harmoniously to ensure smooth production cycles. The absence of a connected system can lead to poor coordination between procurement and production, resulting in wait time for materials; different departments working on isolated systems can lead to communication gaps, and in inventory, there could be overstocking or understocking due to lack of visibility and repetitive data entry can result in errors. This is where an ERP for manufacturing proves invaluable.

A robust ERP for factory management ensures seamless integration between production, procurement, and inventory, providing real-time insights across operations. Process automation eliminates repetitive tasks, reducing the likelihood of errors and delays, which enhances efficiency. With accurate forecasting powered by historical data, businesses can plan better for raw material procurement and sales, avoiding stockouts or excess inventory. Streamlined communication through a unified platform fosters better team collaboration, ensuring smoother workflows and faster decision-making.

Benefits of an ERP for a manufacturing business

1. Real-Time Odoo production and inventory management

An ERP for factory management provides end-to-end visibility into inventory by tracking raw materials, work-in-progress, and finished goods across multiple manufacturing units or warehouses in real-time. This prevents disruptions caused by material shortages. Businesses can better plan manufacturing schedules and know precisely what is available and where. Real-time updates help align procurement with production needs, optimizing manufacturing capacity and reducing lead times.

2. Enhanced Production Planning

ERP systems enable manufacturers to align production schedules with demand forecasts, customer orders, and available resources such as labor, machinery, and raw materials. By integrating sales data and inventory status, ERP for manufacturing ensures that production processes meet delivery deadlines without causing bottlenecks.

3. Automated Workflows

Automation within Odoo’s manufacturing ERP solution simplifies critical manufacturing workflows, such as order processing, procurement, and stock management. Tasks that would otherwise require manual intervention—like purchase order approvals, inventory replenishment, or production scheduling—are automated. Automated notifications and triggers streamline cross-departmental coordination and enable faster order fulfillment.

4. Cost Reduction

An ERP for manufacturing minimizes scrap and overproduction by optimizing material consumption. Better scheduling reduces labor inefficiencies, while real-time Odoo production and inventory management avoids unnecessary stock holding. ERP tools support lean manufacturing practices.

5. Compliance and Traceability

In highly regulated industries, manufacturers must adhere to safety, quality, and environmental compliance standards. An ERP for manufacturing ensures full traceability by tracking batch numbers, serial codes, and production histories and creating detailed audit trails. An ERP makes it easier for businesses to comply with regulatory requirements and conduct internal or external audits. An ERP system generates reports on quality control, safety standards, and product recalls, thus reducing the risk of non-compliance penalties.

Explore the Odoo Manufacturing module for your ERP needs

Odoo is a scalable ERP platform that offers manufacturers a dedicated module for production, inventory, and work order management. The Odoo manufacturing module stands out as an integrated solution that connects multiple aspects of a manufacturing business on one platform.

Why you should consider the Odoo Manufacturing ERP Solution

- Modular Structure: Odoo allows manufacturers to pick only the modules they need initially and expand as the business grows.

- Integration with Other Odoo Apps: The manufacturing module integrates with inventory, purchase, sales, and finance modules. Odoo for manufacturing integrates with hundreds of third-party applications and can be quickly customized to ensure continuous data flow across departments.

- User-Friendly Interface: The intuitive design of the manufacturing module in Odoo makes it easy for employees to adopt the system without extensive training.

- Cost-Effective: Unlike other ERPs, Odoo offers flexible pricing options, making it ideal for small and medium enterprises (SMEs) and large enterprises.

- Large user community: Being open source, Odoo developers constantly create and launch apps specific to industries. Users can also tap into this community to adopt business-specific features.

- Centralized Data Management: Odoo consolidates data—from raw material availability to sales orders—into a unified manufacturing system. This eliminates the need to maintain multiple spreadsheets and tools and ensures everyone can access the latest information.

- Production Scheduling Automation: Automate production scheduling based on demand forecasts and stock availability. Manage dependencies and process work orders in the correct sequence.

- Real-Time Tracking of Operations: Odoo provides real-time insights into production progress. Supervisors can monitor work orders, identify bottlenecks, and adjust schedules.

- Efficient Inventory Management: The Odoo production module integrates inventory management with production planning, ensuring accurate tracking of raw materials and finished goods. The Odoo BOM (Bill of Materials) feature records material consumption automatically.

- Collaboration Between Teams: Production, procurement, and sales teams work on a single platform, thus improving communication. Alerts and notifications keep all stakeholders informed about order status and stock levels.

When should you consider implementing Odoo Manufacturing ERP Solution?

Odoo manufacturing software implementation is ideal when you have the following:

- Disconnected Systems: Your business uses multiple software tools that do not communicate with each other.

- Manual Operations: Processes such as inventory tracking, production planning, and quality control are manual, leading to delays and errors.Need for Scalability: As production grows, it becomes difficult to manage with legacy tools and spreadsheets.

- Production Delays: Lack of visibility into stock levels and resources results in delayed deliveries.

Benefits of Odoo for Manufacturing

1. Integrated Production Management — The Odoo manufacturing module integrates core processes like the Odoo Bill of Materials (BOMs), routing, and work orders. This module connects with other Odoo apps—such as Inventory, Sales, and Procurement—offering manufacturers a 360-degree view of their operations. For example, when a sales order is confirmed, Odoo automatically triggers procurement and production, ensuring coordination between departments.

2. Bill of Materials (BOM) Management — Odoo’s BOM management feature allows the creation of multi-level BOMs, which is essential for industries with intricate assembly lines. Each Odoo Bill of Materials (BOM) can include raw materials, semi-finished components, labor, and operational costs. With Odoo, manufacturers can link BOMs to specific work orders, ensuring that the correct materials are allocated and reducing production errors.

3. Work Order Management — Odoo’s system offers powerful tools for scheduling, tracking, and executing work orders across various centers. It allows manufacturers to assign operators to specific tasks, set dependencies between operations, and sequence activities to avoid bottlenecks. Managers can monitor work order progress in real time and ensure deadlines are met. Odoo for manufacturing also supports automatic triggers for tasks, such as initiating the next step in production once the previous one is completed.

4. Quality Checks at Every Stage — The Odoo manufacturing module allows businesses to embed quality control checks into the production workflow. Quality checkpoints can be defined for critical stages, such as raw material inspection, in-process checks, and final product validation. This ensures that only high-quality products move to the next stage, reducing defects and rework. Odoos’ detailed reporting on quality metrics makes it easier to identify trends and take preventive action. Integration with other modules like Inventory and Sales ensures product failures are recorded and addressed quickly, maintaining consistent product standards.

5. Material Requirements Planning (MRP) — streamline manufacturing with Odoo. Use the MRP feature to align production schedules with inventory availability, demand forecasts, and procurement timelines. By calculating material requirements in advance, the system helps businesses avoid stockouts or overstocking. Odoo MRP also automates purchase orders when stock levels fall below predefined thresholds, keeping production on track. With real-time visibility into material availability, the Odoo manufacturing module enables businesses to prioritize production and adapt quickly to demand or supply chain disruptions.

Now that you understand why you should consider the Odoo manufacturing ERP solution and how it benefits your organization, let’s move on to the Odoo ERP implementation process.

Effective planning is the foundation of a successful ERP implementation. Whether upgrading from legacy systems or adopting Odoo manufacturing software for the first time, these steps will help you stay on track.

Step 1: Assess Operational Needs

Identify pain points in your manufacturing operations, such as production delays, stock mismatches, or procurement inefficiencies. Understanding your needs will help you determine which manufacturing module in Odoo is essential.

Step 2: Set Clear Goals and KPIs

Define measurable objectives, such as improving on-time deliveries, reducing inventory holding costs, and achieving 100% compliance with quality standards. These goals will guide your Odoo manufacturing software implementation and help track progress post-launch.

Step 3: Develop an Implementation Roadmap

A phased approach works best for ERP implementation. Start with the core modules—such as Odoo production inventory management and sales—and gradually add other modules like finance or CRM.

Step 4: Involve Stakeholders Early

Involve employees, managers, and production leads in the planning process. Their input ensures the system addresses real-world challenges and promotes smoother adoption. Training your stakeholders early reduces resistance and ensures everyone is ready when the Odoo manufacturing module goes live.

When implementing the Odoo manufacturing module, it’s essential to address several factors:

1. System Compatibility with Existing Tools

Evaluate whether your current systems—such as production equipment software, procurement platforms, or CRM tools—are compatible with Odoo. An Odoo manufacturing software implementation can integrate with various software solutions, but a compatibility assessment will prevent issues later.

2. Data Migration Plan

Migrating data from old systems to the manufacturing module in Odoo requires planning. Ensure your data is cleaned and standardized before migration to avoid duplicates or inconsistencies.

3. Change Management

Switching to a new ERP system can lead to disruptions if not managed well. Develop a change management strategy to address employee concerns and provide adequate support during the transition phase.

4. Timeline and Budget

Set realistic timelines and budgets for implementation to streamline manufacturing with Odoo. Odoo’s modular nature allows phased deployment, but managing time efficiently is crucial to avoid cost overruns.

How Odoo Production and Inventory Management aligns with a Manufacturers needs

Manufacturers operate in fast-paced environments where delays or disruptions can have a cascading effect on productivity. Odoo ERP for manufacturing aligns perfectly with these needs by offering a range of features tailored for production-heavy businesses.

1. Material Requirements Planning (MRP)

Odoo’s MRP module ensures manufacturers have the suitable materials at the right time. It automatically generates procurement orders based on production schedules and current stock levels, preventing shortages.

2. Multi-Warehouse Management

For those with multiple production units or warehouses, Odoo ERP for manufacturing provides a centralized system to track stock movements. Inventory can be transferred across locations, with each transaction logged for traceability.

3. Production Costing and Analysis

As an ERP for factory management, Odoo enables businesses to monitor production costs, including labor, materials, and overheads. With real-time analytics, managers can compare planned vs. actual costs and make adjustments where necessary.

4. Quality Control at Every Stage

Manufacturers can set quality control points throughout production, ensuring products meet regulatory standards and customer expectations. The odoo production module also stores inspection reports, making audits easier.

5. Flexible BOM Management

The Odoo BOM (Bill of Materials) feature supports multi-level BOMs and allows businesses to track component usage in detail. BOM changes can be managed effortlessly, and Odoo reflects these changes in related processes.

Odoo Manufacturing Solutions for SMEs

Small and medium enterprises (SMEs) often face unique challenges, such as tight budgets, limited workforces, and the need to compete with larger players. The Odoo manufacturing module offers a scalable and affordable ERP that caters to these requirements.

1. Modular Flexibility for Growth: Odoo manufacturing software’s modular nature is a big advantage for SMEs. Businesses can start small by implementing modules such as production and inventory management and expand as their operations grow.

2. Cost-Effective Odoo Manufacturing Solutions for SMEs: Traditional ERP systems come with high upfront costs that SMEs cannot always afford. Odoo’s open-source structure allows businesses to access tools at a fraction of the cost, with affordable licensing options for additional modules.

3. Efficient Resource Planning and Utilization: This ERP system’s integrated approach enables SMEs to streamline manufacturing with Odoo. Linking production, procurement, and sales ensures better utilization of raw materials and minimizes waste.

4. Better Decision-Making with Real-Time Data: SMEs often need to pivot quickly in response to changing market conditions. Real-time reporting dashboards in the Odoo manufacturing module enable managers to monitor operations closely and make data-driven decisions to stay competitive.

Why Odoo Manufacturing Solution is Ideal for SMEs

For those looking to streamline manufacturing with Odoo, here’s why this ERP is ideal for SMEs

User-Friendly Interface: SMEs may not have dedicated IT departments, and the Odoo manufacturing module’s easy-to-use interface ensures employees across departments can quickly adapt.

Cloud and On-Premise Deployment: Odoo offers flexible deployment options, allowing SMEs to choose between on-premise and cloud-based solutions based on their infrastructure and budget.

Customization to Fit Industry Needs: Odoo’s manufacturing ERP solution can be tailored to fit the specific needs of industries like textile manufacturing, food production, real estate, and chemical processing, ensuring SMEs get the features they need without unnecessary complexity.

Navabrind IT Solutions — Your Odoo Partner for Manufacturing ERP

Why Navabrind IT Solutions should be your Odoo partner for Manufacturing ERP Implementation

Selecting the right Odoo partner to implement the manufacturing ERP is essential for smooth ERP adoption. An experienced partner can help your businesses configure the system based on your needs, provide hands-on employee training, and ensure the ERP runs smoothly after deployment.

Why Work with Navabrind IT Solutions?

If you need an Odoo partner to implement the manufacturing ERP, Navabrind IT Solutions is the right choice. We specialize in implementing the Odoo manufacturing ERP for businesses of all sizes. As an Odoo Gold Partner, we bring extensive expertise in deploying Odoo across various industries, including manufacturing, retail, real estate, and logistics. Our approach ensures a customized ERP solution tailored to your operational needs.

Need to Implement Odoo for Manufacturing? Here’s What Navabrind IT Solutions Offers

- End-to-End Implementation Support: We assist at every stage, from system design to deployment and beyond.

- Customization and Configuration: We tailor the manufacturing modules in Odoo to fit your workflows.

- Employee Training and Support: We ensure your workforce is well-trained to use the ERP efficiently.

- Ongoing Maintenance and Upgrades: We provide long-term support and system updates to keep your ERP running optimally.

Implementing Odoo for manufacturing allows businesses to streamline operations, improve efficiency, and reduce costs. From real-time inventory tracking to automated production scheduling, Odoo ERP offers an all-in-one solution that integrates seamlessly across departments. Whether you are a large enterprise or an SME, Odoo’s modular design and cost-effective structure make it the ideal ERP for factory management.

If you want an Odoo partner to implement the manufacturing ERP, contact Navabrind IT Solutions to future-proof your business operations. A properly planned implementation will ensure a smooth transition to the ERP, empowering you to meet production targets and grow your business efficiently.

Frequently Asked Questions

1. What is Odoo manufacturing software?

Odoo manufacturing software is part of the Odoo ERP platform. The software enables businesses to efficiently manage production processes, inventory tracking, work orders, and Odoo BOM (Bill of Materials). Open-source Odoo ERP integrates with other Odoo modules, such as procurement and sales, to provide a unified platform for managing operations.

The manufacturing module in Odoo supports Material Requirements Planning (MRP), allowing companies to align production schedules with demand forecasts and available resources. With built-in tools for quality management and traceability, businesses can maintain high production standards and comply with industry regulations. Scalable and modular, this ERP for manufacturing caters to both SMEs and large enterprises.

2. Is Odoo ERP suitable for the manufacturing industry?

Yes, Odoo ERP is suitable for the manufacturing industry. Its modular design allows businesses to manage work orders, BOMs, routing, inventory, and MRP within a unified system. The manufacturing module in Odoo integrates core functions—such as procurement, sales, and finance—to eliminate silos and improve real-time data flow. Odoo ERP for manufacturing automates repetitive tasks like order processing and stock replenishment, reducing errors and enhancing productivity. With real-time visibility into operations, manufacturers can optimize resources, avoid bottlenecks, and quickly respond to disruptions. The quality management and traceability tools in the Odoo production module help ensure compliance and reduce waste. Scalable for SMEs and large enterprises, Odoo’s cloud-based access and customizable features make it a flexible, cost-effective solution that drives efficiency and competitiveness.

3. What are the benefits of Odoo manufacturing module?

The benefits of the Odoo manufacturing module are its ability to streamline operations, enhance efficiency, and provide end-to-end visibility. The Odoo Bill of Materials (BOM), work order tracking, and MRP capabilities allow manufacturers to optimize production planning, reduce waste, and avoid stockouts. Integrating with other Odoo modules—such as procurement, sales, and accounting—enables coordination between departments. Quality control checks throughout production ensure products meet required standards, helping businesses maintain consistency and compliance. Scalable for both SMEs and large enterprises, Odoo for manufacturing improves productivity, lowers costs, and enhances operational agility.

4. Is Odoo for manufacturing free?

The manufacturing module in Odoo is available in the community and enterprise editions, but the free version has limitations. The Odoo Community Edition offers basic manufacturing features at no cost, including essential tools like BOM management and work orders, making it a viable option for small businesses with more straightforward needs. However, more advanced features—such as MRP, quality control, automated workflows, and advanced reporting—are only available in the Odoo Enterprise Edition, which requires a subscription. The enterprise version also includes professional support, hosting options, and seamless integration with other Odoo modules, making it more suitable for businesses with complex manufacturing operations. While this Odoo production module offers flexibility through its free version, scaling businesses often opt for the paid edition to experience the platform’s full potential.

5. Can Odoo integrate with other manufacturing tools and software?

Yes, the manufacturing module in Odoo can be integrated with various manufacturing tools and software, enhancing operational efficiency and data flow across systems. Odoo ERP can connect with third-party tools for CAD, PLM (Product Lifecycle Management), IoT devices, warehouse management systems, and industry-specific solutions through APIs and connectors. This integration enables real-time data exchange, ensuring that production schedules, inventory levels, and procurement processes remain synchronized across platforms. Odoo’s modular design allows it to work alongside other software for supply chain management, quality control, and financial reporting, giving manufacturers the flexibility to maintain or expand existing systems while leveraging Odoo’s capabilities. The Odoo Integration Studio makes developing custom connectors tailored to business needs easy, ensuring smooth interoperability without disrupting workflows.

Related Articles

-

Post

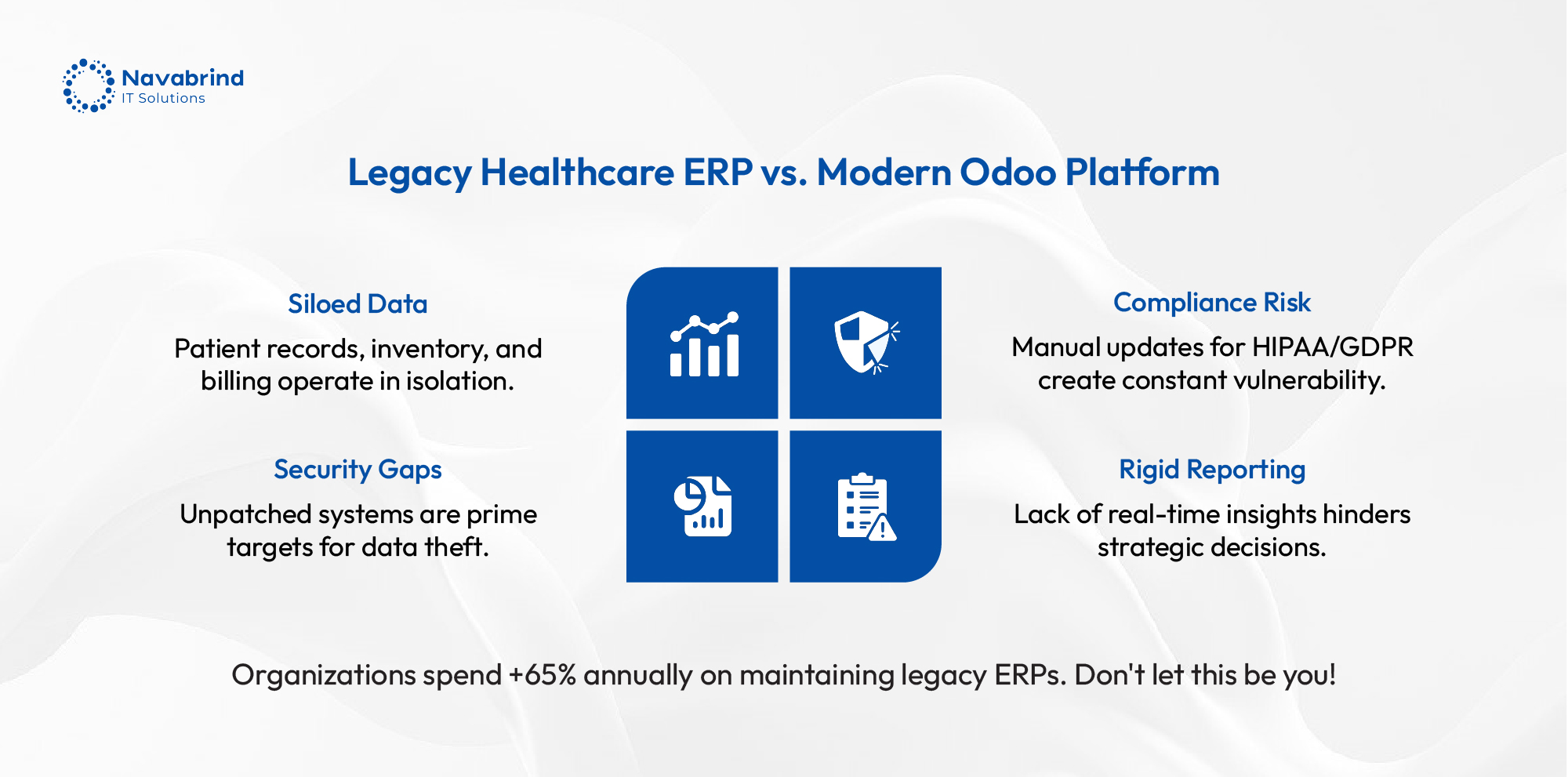

From Legacy Healthcare ERP to Odoo ERP: Why You Need Expert Odoo Migration Help

From Legacy Healthcare ERP to Odoo ERP: Why You Need Expert Odoo Migration Help February 11, 2026 Posted by: Tony Category: Uncategorized No Comments Why Healthcare Organizations Need Odoo ERP Migration Legacy healthcare ERP systems create barriers to efficiency. They are expensive to maintain, and struggle to integrate tools. This disconnect impacts patient care coordination, -

Post

From LLMs to Agentic AI: A Practical Guide to What They Mean and How to Choose

From LLMs to Agentic AI: A Practical Guide to What They Mean and How to Choose February 4, 2026 Posted by: Tony Categories: Artificial Intelligence, Blog No Comments As definitions, use cases, expectations, and investments around Large Language Models (LLMs), Retrieval-Augmented Generation (RAG), AI agents, and agentic AI continue to expand, many individuals and organizations -

Post

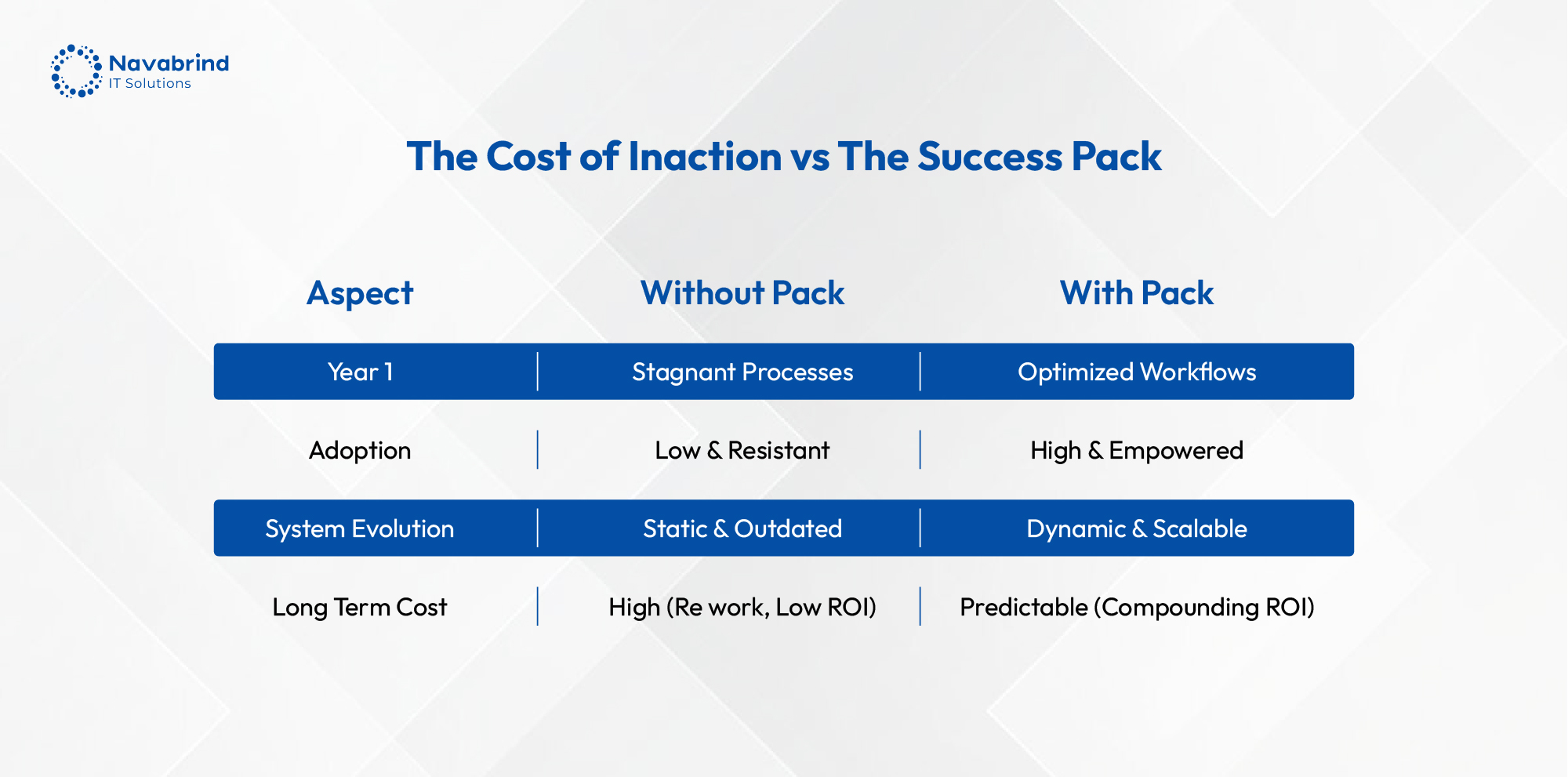

Beyond Go-Live: How Your Odoo Success Pack Drives Real, Long-Term ROI

Beyond Go-Live: How Your Odoo Success Pack Drives Real, Long-Term ROI February 3, 2026 Posted by: Category: Uncategorized No Comments The Implementation Myth Businesses mistakenly measure ERP success by completing the implementation phase while the actual measure of value is the operational transformation unlocked after go-live. The Odoo Success Pack is the framework engineered to

How can we help you?

Get in touch with a solutions consultant that can share best practices and help solve specific challenges.