The Cost Benefits of Implementing Odoo ERP in Manufacturing

- May 30, 2025

- Posted by: Vasanth Anantharaman

- Categories: Blog, Odoo Manufacturing, Uncategorized

The manufacturing sector is undergoing a profound digital transformation. Competition is intensifying, global supply chains are becoming more complex, and legacy systems and manual processes no longer offer manufacturers the agility needed to stay competitive.

This is where Odoo ERP for Manufacturing stands out. As an all-in-one, modular, and scalable platform, Odoo offers comprehensive manufacturing ERP solutions that are both powerful and economically viable. Whether optimizing inventory, automating production workflows, or enhancing traceability, Odoo delivers tangible ERP savings for manufacturing businesses of all sizes.

Understanding the Odoo ERP cost benefits is critical for manufacturers evaluating digital investments. From its open-source flexibility to its customizable modules, Odoo offers a budget-friendly ERP solution for manufacturing businesses. It addresses operational and financial pain points—helping reduce manufacturing costs with ERP, improve resource utilization, and accelerate return on investment.

Why Manufacturers Need an ERP System Today

Modern manufacturing environments are complex. However, many manufacturers still struggle with siloed systems, disconnected processes, and outdated tools that hinder productivity and visibility.

Challenges like inventory inaccuracies, production delays, procurement inefficiencies, and limited oversight across the supply chain highlight the urgent need for robust manufacturing ERP solutions. Manual data entry, spreadsheets, and disconnected tools slow down operations and increase the risk of errors and costly rework.

Odoo centralizes production, inventory, procurement, and supply chain functions into a unified platform— offering real-time visibility, automated workflows, and actionable insights. Manufacturers benefit from ERP savings for manufacturing by reducing lead times.

The cost-saving advantages of Odoo ERP in production are measurable. Whether you’re a small-scale factory or a large enterprise, Odoo delivers a budget-friendly ERP solution for manufacturing businesses that scale with your operations. With its modular design and open-source architecture, Odoo pricing for manufacturers remains competitive, offering high functionality at a fraction of traditional ERP costs.

The Odoo ERP cost benefits go beyond the initial investment. Lower implementation overhead, faster deployment, and minimal licensing fees contribute to the strong ROI of Odoo ERP. With fewer manual tasks and increased automation, manufacturers can achieve higher throughput and reduce manufacturing costs with ERP.

Adopting Odoo isn’t just a technology upgrade—it’s a strategic move. The financial benefits of implementing Odoo in manufacturing and the ability to compare Odoo ERP cost vs. value for factory operations make it a compelling solution for manufacturers ready to embrace digital transformation.

Key Cost Benefits of Odoo ERP in Manufacturing

Choosing the right ERP is critical not just for operational efficiency but also for managing long-term costs. Odoo ERP for manufacturing stands out by delivering a powerful blend of functionality and affordability. Here are the core ways manufacturers can realize substantial financial benefits by implementing Odoo:

A. Lower Total Cost of Ownership

A significant Odoo ERP cost benefit lies in its open-source foundation. Unlike traditional ERP vendors that require expensive licensing and lock-in contracts, Odoo offers scalable pricing options with the flexibility to pay only for the modules your factory needs.

This budget-friendly ERP solution for manufacturing businesses eliminates the burden of recurring licensing fees and restrictive vendor agreements. The result? A lower Odoo implementation cost and an agile platform that grows with your operations. Manufacturers enjoy greater control over upgrades and customization while minimizing long-term overheads.

B. Reduced Operational Costs

Odoo ERP helps reduce manufacturing operational costs by automating time-consuming processes such as procurement, inventory tracking, production scheduling, and quality control. Real-time visibility across departments leads to less material wastage—lowering the cost per unit produced.

Automated workflows reduce downtime and streamline communication between procurement, the shop floor, and logistics. Odoo ERP’s cost-saving advantages in production translate into leaner operations and agile supply chain responses.

C. Improved Labor Efficiency

Labor accounts for a significant portion of manufacturing expenses. Odoo boosts workforce productivity through intelligent scheduling, task automation, and performance tracking. By minimizing manual data entry and reducing administrative overhead, employees can focus on high-value tasks.

Manufacturers benefit from fewer manual interventions, better workforce allocation, and optimized shift management. With Odoo ERP for manufacturing, your team operates more efficiently, translating into faster turnaround times, fewer bottlenecks, and measurable improvements in labor utilization—another compelling reason behind the strong Odoo ERP ROI.

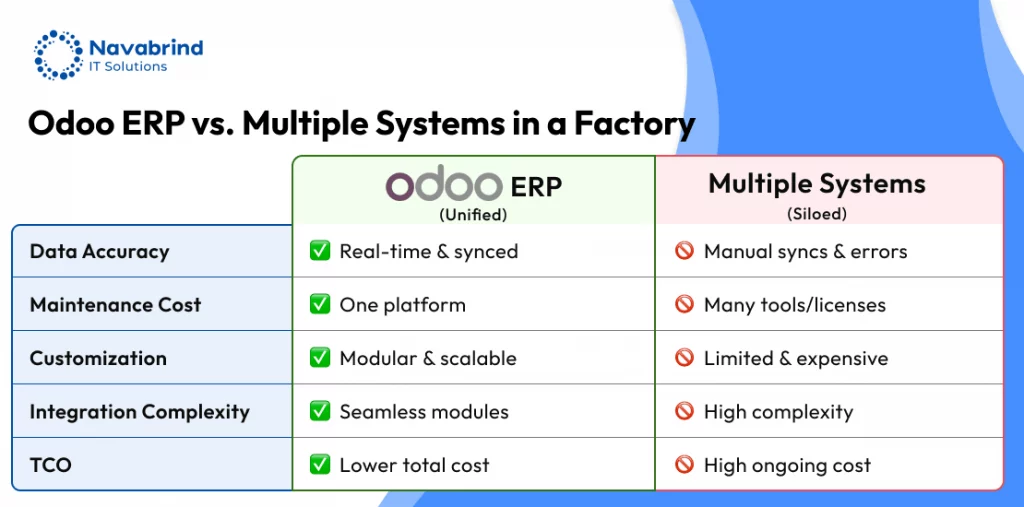

D. Consolidation of Multiple Systems

Many manufacturers rely on a patchwork of tools—spreadsheets for inventory, separate software for accounting, and isolated systems for production or sales. Odoo unifies these functions into a single, integrated platform.

This consolidation of multiple systems simplifies workflows and eliminates redundant software costs. Companies experience reduced licensing and maintenance overhead, improved data accuracy, and real-time collaboration across departments. For businesses comparing Odoo ERP cost vs. value for factory operations, the ability to streamline tools and remove silos is a major advantage.

Odoo Implementation Cost: What to Expect

When evaluating manufacturing ERP solutions, implementation cost is a key consideration—especially for small and mid-sized factories aiming for high returns on a controlled budget. Odoo ERP for manufacturing is widely regarded as a cost-effective ERP for factories, offering scalable pricing and modular deployment. However, understanding the actual Odoo implementation cost involves more than just the software license.

Here’s a breakdown of what to expect when budgeting for your Odoo deployment, and a comparison to traditional ERP platforms.

1. Licensing Costs (Odoo Enterprise)

Odoo offers Community (free, open-source) and Enterprise (paid, with enhanced features and support). For manufacturers seeking robust functionality—like advanced inventory management, MRP, and automated quality checks—Odoo Enterprise is the preferred option.

Odoo pricing for manufacturers is based on:

- Number of users

- Number and type of modules

- Cloud hosting or on-premise deployment

Despite these considerations, Odoo’s subscription fees remain significantly lower than legacy systems like SAP, Oracle, or Microsoft Dynamics, delivering substantial ERP savings for manufacturing operations.

2. Customization Costs

No two factories operate the same way, and customizing Odoo ERP for manufacturing processes is often necessary. Customization may involve adapting workflows, reports, dashboards, or building bespoke modules for specific operations like batch tracking, quality audits, or machinery integration.

This is where Odoo ERP cost benefits shine—thanks to its open-source nature, customization is faster and more affordable than proprietary ERP systems. Manufacturers can start to lean and expand functionality over time, creating a budget-friendly ERP solution for manufacturing businesses.

3. Integration Costs

Successful ERP implementation also requires integrating Odoo with other tools—such as CAD software, shop floor equipment, CRMs, e-commerce platforms, or IoT sensors.

Odoo’s modular architecture and rich API ecosystem allow for seamless integration at a fraction of the cost compared to closed ERP systems. This flexibility enhances the Odoo ERP ROI by enabling better data flow across departments and reducing inefficiencies caused by siloed software tools.

4. Training Costs

Implementing an ERP is only effective if your workforce knows how to use it. Training costs vary depending on the team size, number of modules deployed, and the delivery method (in-person, virtual, or on-demand).

Odoo’s user-friendly interface helps shorten the learning curve, resulting in lower training costs than traditional ERP systems. Faster user adoption means manufacturers can start realizing the cost-saving advantages of Odoo ERP in production much sooner.

5. Support & Maintenance

Whether you choose an implementation partner or manage support in-house, ongoing maintenance is vital. This includes bug fixes, module updates, security patches, and user support.

Unlike traditional ERP systems with expensive annual maintenance contracts, Odoo’s support ecosystem is flexible and competitive—allowing manufacturers to pay for only the support they need. This leads to reduced manufacturing costs with ERP and a higher long-term Odoo ERP ROI.

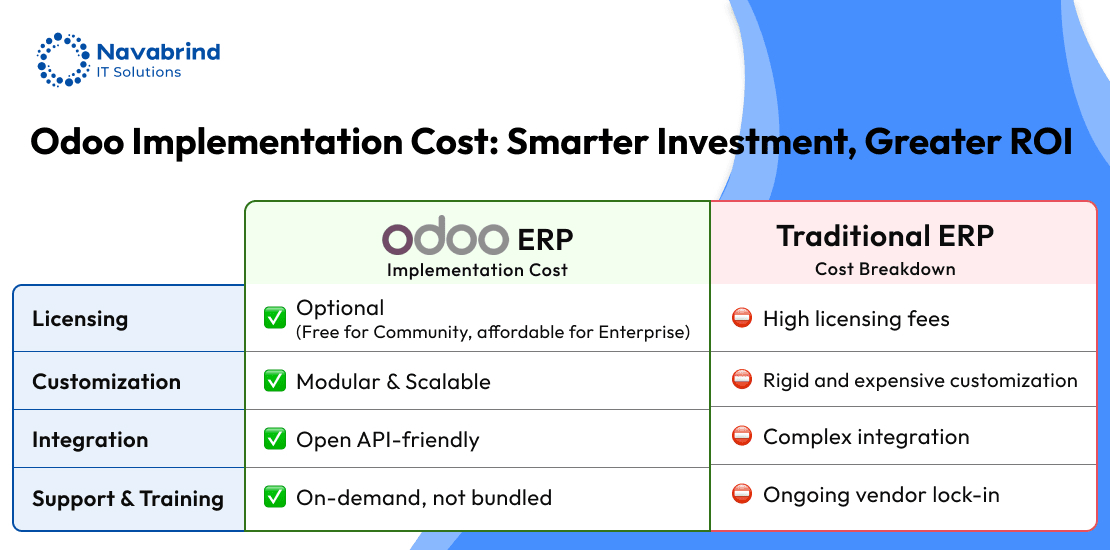

6. Odoo Implementation Cost vs. Traditional ERP Platforms

|

Feature |

Odoo ERP for Manufacturing |

Traditional ERP Systems |

|

Licensing |

Modular, low-cost, per-user/module |

Expensive upfront licenses |

|

Customization |

Fast and open-source friendly |

Time-consuming, costly, vendor-locked |

|

Integration |

Flexible APIs, modular |

Complex and high-cost integrations |

|

Training |

Intuitive UI, lower training cost |

Steep learning curve, expensive |

|

Support & Maintenance |

Affordable and scalable |

High annual support fees |

This comparison shows why Odoo ERP cost vs. value for factory operations is so favorable. From reduced TCO to long-term operational efficiencies, Odoo emerges as a financially sound investment for manufacturers seeking scalable, modern ERP capabilities.

Understanding the ROI of Odoo ERP in Manufacturing

The return on investment (ROI) is a critical factor for manufacturers evaluating ERP systems. Beyond initial implementation, the ability to drive efficiency, reduce costs, and scale operations determines the long-term value of any solution. Odoo ERP for Manufacturing offers compelling ROI through automation, integration, and real-time visibility—empowering businesses to operate leaner and smarter.

Let’s explore the measurable benefits and how quickly manufacturers can begin to see a return on their Odoo implementation cost.

1. Measurable Benefits of Odoo ERP in Manufacturing

a. Reduced Errors and Rework

Manual data entry and disjointed processes are major sources of errors in manufacturing environments. With Odoo’s integrated platform—spanning inventory, production, procurement, and sales—manufacturers can significantly reduce data inconsistencies, production mistakes, and compliance issues. These gains contribute directly to ERP savings for manufacturing operations.

b. Faster Lead Times

Odoo streamlines the manufacturing workflow—from order intake to delivery—with automated scheduling, smart procurement, and accurate inventory tracking. This reduces production bottlenecks and shortens cycle times, a vital advantage for just-in-time or make-to-order businesses. The result is improved responsiveness and faster fulfillment, which enhances customer satisfaction while lowering overhead.

c. Higher Throughput and Productivity

By replacing legacy systems or spreadsheets with an intuitive and unified ERP, teams spend less time switching between tools and more time executing. Odoo’s real-time data visibility and mobile accessibility enable quicker decision-making and faster approvals across the factory floor, leading to increased throughput without adding headcount.

These cost-saving advantages of Odoo ERP in production improves the bottom line and positions manufacturers to handle growth more effectively.

2. Timeline for ROI Realization

Unlike traditional ERP systems, where the return on investment might take years, Odoo ERP ROI can be realized much sooner—especially for small and mid-sized factories.

Typical ROI milestones for Odoo implementation include:

|

Timeframe |

Milestone |

|

0–3 Months |

Reduced manual work, basic process automation, improved data visibility |

|

3–6 Months |

Optimized inventory, fewer stockouts, enhanced production planning |

|

6–12 Months |

Lower operating costs, better vendor/customer coordination, faster deliveries |

|

12+ Months |

Full ROI through reduced waste, improved margins, and scalability |

This accelerated timeline is why Odoo is often described as a budget-friendly ERP solution for manufacturing businesses.

3. The Value Equation: Cost vs. Return

When comparing Odoo ERP cost vs. value for factory operations, the numbers speak for themselves:

- Lower total cost of ownership than legacy systems

- Minimal downtime during implementation

- Faster employee adoption due to user-friendly UI

- Scalable pricing aligned with business growth

Combined, these factors make Odoo a cost-effective ERP for factories with a high potential for long-term return. The financial benefits of implementing Odoo in manufacturing are tangible, trackable, and sustainable.

Odoo ERP Cost vs. Value for Factory Operations

When evaluating any ERP investment, especially in the manufacturing sector, decision-makers must go beyond upfront expenses and assess long-term value. Odoo ERP for Manufacturing offers an exceptional value proposition—balancing affordability with robust functionality, scalability, and adaptability. Understanding the Odoo ERP cost vs. value for factory operations is key to unlocking its full strategic potential.

1. Total Cost of Ownership (TCO) vs. Long-Term Value

The Odoo Implementation Cost—including setup, customization, training, and support—is often significantly lower than that of traditional ERP platforms. Its modular, open-source nature allows manufacturers to start with essential features and scale as needed without committing to unnecessary licensing fees or expensive integrations.

This flexible approach contributes to lower TCO while delivering immense long-term value in the form of:

- Agility – Rapid adaptation to market or production changes.

- Scalability – Easy addition of new modules or users as the business grows.

- Adaptability – Quick customization to match evolving operational needs.

This makes Odoo a budget-friendly ERP solution for manufacturing businesses and one that evolves with your business over time.

2. Future-Proofing Your Operations

Investing in Odoo today prepares your factory for tomorrow’s challenges. As manufacturers seek to digitize operations and increase automation, Odoo offers the technological foundation to:

- Reduce manufacturing costs with ERP through real-time visibility, predictive inventory, and smart scheduling.

- Drive ERP savings for manufacturing with accurate forecasting, minimal downtime, and streamlined procurement.

- Enable cost-saving advantages of Odoo ERP in production through reduced manual intervention and centralized control.

Over time, these efficiencies compound, generating exponential savings and greater operational resilience—especially in volatile or competitive markets.

3. Value Beyond Software Costs

Odoo pricing for manufacturers is designed to eliminate vendor lock-in and bloated IT overhead. But the real value of Odoo lies in what it replaces:

- Legacy systems that don’t talk to each other

- Spreadsheets prone to error

- Manual processes that drain labor hours

- Siloed data that slows decision-making

By consolidating these into one unified platform, manufacturers gain a strategic advantage. This consolidation is a core reason why the financial benefits of implementing Odoo in manufacturing far outweigh the initial investment.

4. Maximizing ROI of Odoo ERP

Ultimately, the ROI of Odoo ERP stems from its ability to accelerate business outcomes while keeping costs manageable:

- Increased throughput with fewer resources

- Greater customer satisfaction through faster fulfillment

- Accurate, real-time data to drive decisions

- Reduced material and labor waste

Manufacturers seeking a cost-effective ERP for factories will find Odoo’s ecosystem perfectly aligned with lean manufacturing goals and long-term digital transformation strategies.

Frequently Asked Questions

1. How does Odoo ERP help reduce manufacturing operational costs?

Odoo ERP for Manufacturing offers a comprehensive suite of tools designed to streamline production, inventory management, and supply chain operations. By automating routine workflows, such as order processing, stock tracking, and quality control, Odoo reduces the need for manual data entry and minimizes human errors. This automation directly contributes to ERP savings for manufacturing by lowering labor costs and boosting overall operational efficiency. Manufacturers can track inventory in real-time, improving accuracy and reducing excess stock or shortages, which are standard cost drivers in production environments.

Another key cost-saving advantage of Odoo ERP in production is its ability to optimize resource allocation. The platform enables more precise production scheduling and workforce management, reducing downtime and idle time. This improved utilization of labor and machinery leads to fewer disruptions and waste, further reducing manufacturing costs. Additionally, integrated reporting tools provide actionable insights, allowing managers to identify bottlenecks and inefficiencies driving operational expenses.

The financial benefits of implementing Odoo in manufacturing extend beyond direct cost reductions. Odoo’s modular and scalable design offers a budget-friendly ERP solution for manufacturing businesses, making it accessible to companies of all sizes. Unlike traditional ERP systems with high upfront and ongoing costs, Odoo provides a cost-effective ERP for factories, helping companies realize a strong Odoo ERP ROI by lowering both capital and operational expenditure. This blend of cost control, automation, and data-driven decision-making clearly demonstrates how Odoo ERP helps reduce manufacturing operational costs.

2. What is the typical implementation cost of Odoo ERP for manufacturing businesses?

The Odoo Implementation Cost for manufacturing companies depends on several factors, including the scope of deployment, customization requirements, the number of users, and integration complexity. Odoo offers a free open-source Community version and a paid Enterprise edition with additional features and support. The modular pricing structure means many manufacturers pay for the specific Manufacturing ERP Solutions they need. This makes Odoo a highly cost-effective ERP for factories compared to traditional ERP platforms that charge hefty licensing fees upfront.

Customization and integration are significant components of the total implementation cost. Many manufacturing businesses require tailor-made workflows to fit unique production processes or connect Odoo ERP with other software such as CRM, e-commerce platforms, or supply chain tools. While these customizations increase initial costs, they enhance system efficiency and reduce operational expenses in the long-term. When evaluating Odoo pricing for manufacturers, it is crucial to consider these factors alongside the projected ERP savings for manufacturing that come from improved process automation and data accuracy.

Compared to legacy ERP systems, Odoo offers a more affordable entry point and lower total cost of ownership (TCO). The transparent pricing and lack of vendor lock-in improve Odoo ERP Cost Benefits. When combined with quicker deployment times and ongoing vendor support, manufacturers often experience a faster path to profitability and a better ROI of Odoo ERP. This makes Odoo not only a practical but a financially smart choice for companies looking to reduce manufacturing costs with ERP while gaining advanced digital capabilities.

3. How does Odoo’s pricing model benefit small and mid-sized manufacturers?

Odoo’s pricing model is uniquely designed to support small and mid-sized manufacturers by offering flexibility and scalability. Unlike traditional ERP solutions that often require large upfront investments and long-term contracts, Odoo allows manufacturers to pay only for the modules and users they need. This modular pricing approach makes Odoo a budget-friendly ERP solution for manufacturing businesses, minimizing the Odoo implementation cost and enabling smaller companies to access powerful Manufacturing ERP Solutions without breaking the bank.

Because Odoo operates on a subscription model for its Enterprise edition, manufacturers can scale their ERP usage up or down as their business grows or shifts. This adaptability ensures companies avoid paying for unused features or licenses, making Odoo a cost-effective ERP for factories. Additionally, the open-source Community version provides an entry point with no licensing fees, allowing manufacturers to start small and gradually transition to more advanced capabilities as their operational complexity increases. This flexibility results in substantial ERP savings for manufacturing companies compared to more rigid pricing models.

Odoo’s pricing model eliminates vendor lock-in, allowing manufacturers to customize and maintain their systems with multiple providers if desired. This freedom enhances the Odoo ERP Cost Benefits by reducing dependency on a single vendor and lowering long-term maintenance costs. By aligning costs directly with actual usage and growth, Odoo’s pricing strategy empowers small and mid-sized manufacturers to deploy an advanced ERP platform that delivers value while respecting their budget constraints.

4. What kind of ROI can manufacturers expect from implementing Odoo ERP?

Manufacturers implementing Odoo ERP for Manufacturing typically experience a measurable return on investment (ROI) driven by several key operational improvements. Faster production cycles are one of the most immediate benefits, as Odoo automates scheduling, order tracking, and quality control processes. This leads to reduced lead times and increased throughput, allowing factories to meet demand more efficiently. Additionally, Odoo’s real-time data visibility helps minimize errors and rework, cutting waste and saving costs — all contributing factors to a strong Odoo ERP ROI.

Reduced downtime and better resource allocation are crucial in driving ROI. Odoo’s integrated platform enables manufacturers to identify bottlenecks and optimize workforce deployment, ensuring machines and personnel are used to their fullest potential. These improvements reduce idle time and operational inefficiencies, helping manufacturers reduce manufacturing costs with ERP. The ability to consolidate multiple functions — from inventory to accounting — further cuts administrative overhead, amplifying overall savings and financial benefits.

Most manufacturers report achieving a positive ROI within 12 to 18 months of Odoo Implementation Cost recovery. The cost-saving advantages of Odoo ERP in production extend beyond initial implementation, as continuous improvements and system scalability allow businesses to keep pace with changing market demands. When considering Odoo ERP cost vs. value for factory operations, the financial benefits of implementing Odoo in manufacturing consistently outweigh the investment, making it a compelling choice for companies seeking long-term efficiency and growth.

5. Can Odoo ERP replace multiple standalone systems in a factory?

Yes, Odoo ERP for Manufacturing is designed to consolidate numerous standalone systems into a single, unified platform, covering key functions such as inventory management, sales, accounting, procurement, and human resources. This consolidation simplifies factory operations by providing a centralized source of truth, which improves data accuracy and operational visibility. Manufacturers can streamline workflows and reduce manual data entry, by eliminating the need for multiple disconnected tools, ultimately enhancing productivity and decision-making.

The Odoo ERP Cost Benefits of replacing disparate systems with a single solution are significant. When factories use multiple standalone software tools, they face high cumulative licensing fees, complex integrations, and ongoing maintenance costs. Odoo’s modular design means companies pay for only what they need, and its seamless integration across modules removes the hidden costs associated with data silos and incompatible systems. This leads to substantial ERP savings for manufacturing and positions Odoo as a cost-effective ERP for factories seeking to reduce overhead while enhancing operational efficiency.

Additionally, consolidating systems with Odoo improves the overall ROI of Odoo ERP by lowering the Odoo Implementation Cost related to managing multiple vendors and software platforms. Reducing system complexity cuts training time and simplifies IT support, providing ongoing financial benefits. When assessing Odoo ERP cost vs. value for factory operations, manufacturers find that the integrated platform delivers more value than the combined standalone systems it replaces. This makes Odoo an attractive, budget-friendly ERP solution for manufacturing businesses focused on long-term cost reduction and streamlined operations.

Schedule a conversation with us now!

Related Articles

-

Post

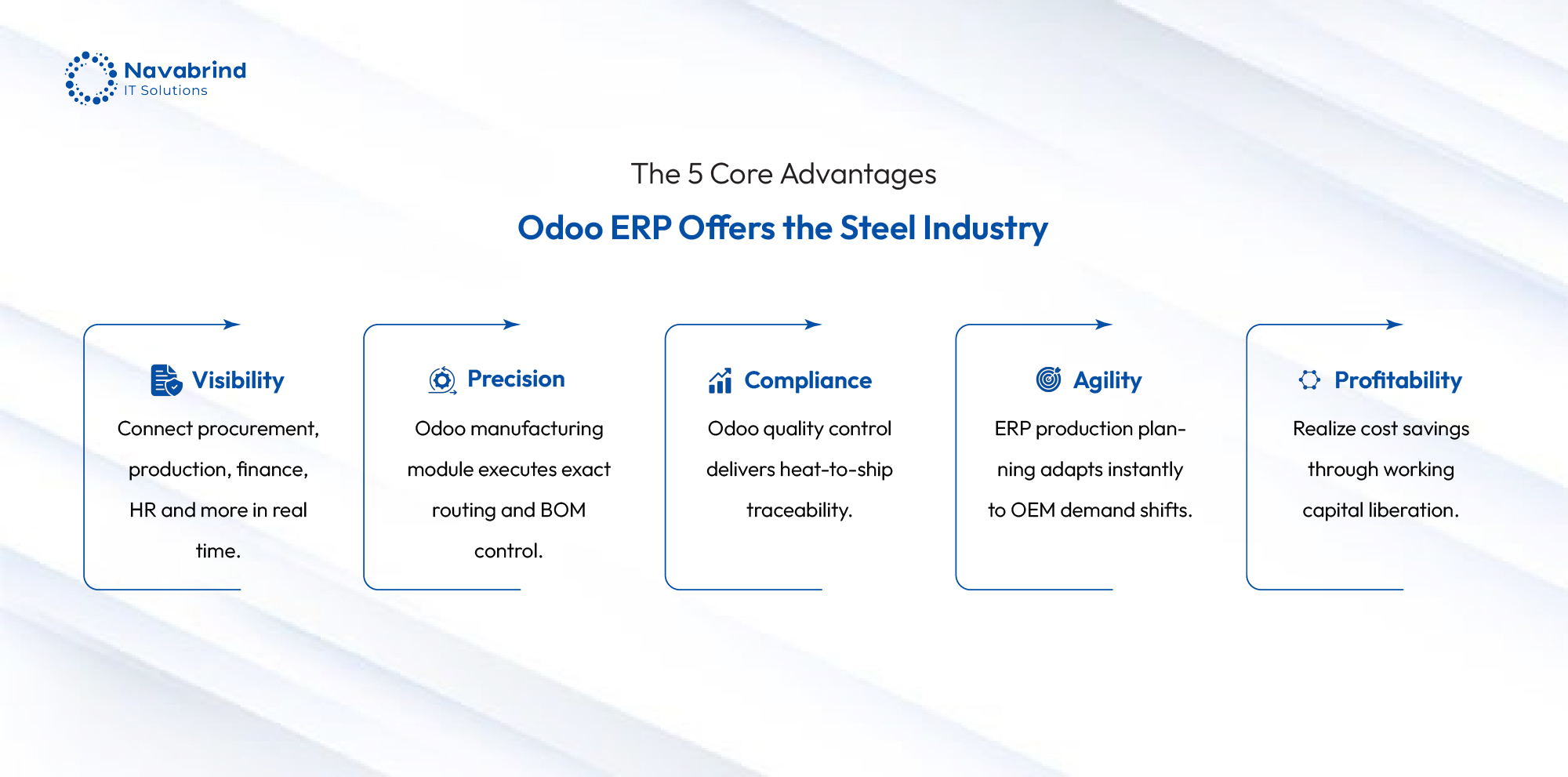

How Odoo ERP Drives Efficiency in the Steel Industry

How Odoo ERP Drives Efficiency in the Steel Industry February 18, 2026 Posted by: Tony Categories: Blog, Odoo No Comments The High-Stakes Race of Auto Parts Manufacturing Your OEM demands a production schedule shift, but procurement can’t confirm steel availability. The sales team lacks real-time inventory data for a quote and your shop floor operates -

Post

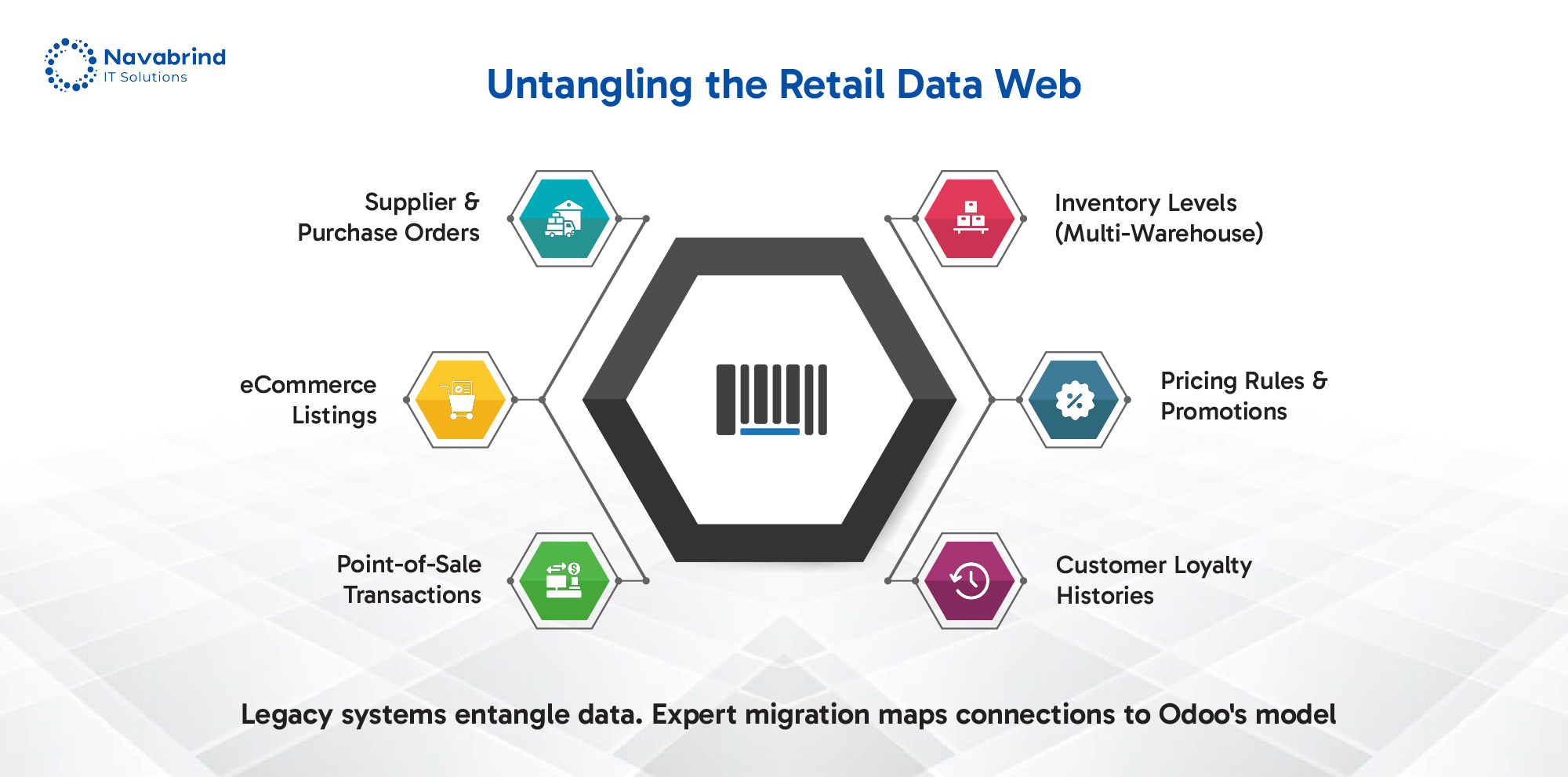

Odoo Database Migration Guide: From Homegrown Retail ERP to Odoo ERP Without Downtime

Odoo Database Migration Guide: From Homegrown Retail ERP to Odoo ERP Without Downtime February 18, 2026 Posted by: Tony Category: Uncategorized No Comments The Need for Smooth Odoo Database Migration If your outdated software, disparate applications, and an unsupported ERP begin to hinder work, you are no longer dealing with a minor technical issue, but -

Post

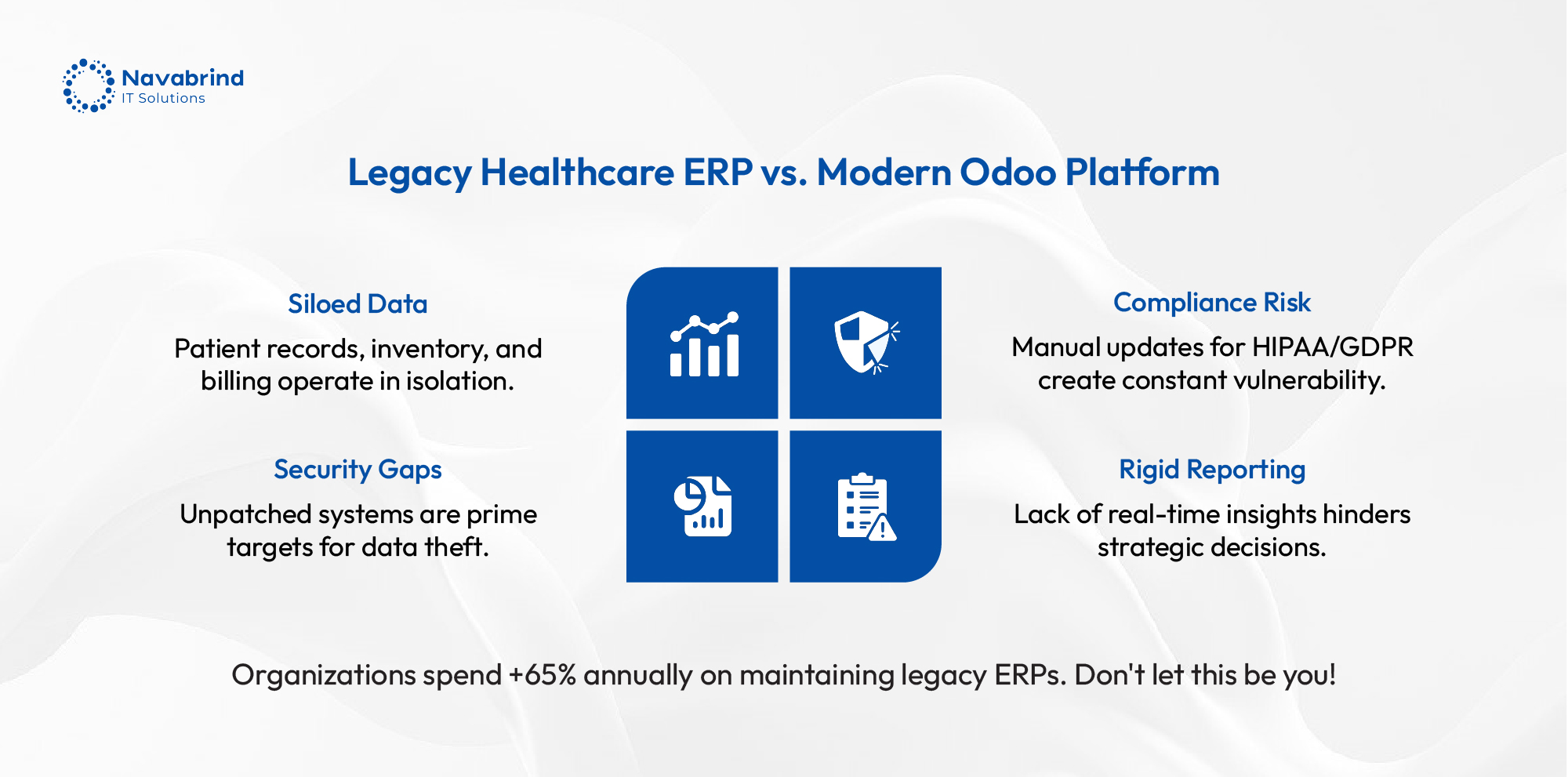

From Legacy Healthcare ERP to Odoo ERP: Why You Need Expert Odoo Migration Help

From Legacy Healthcare ERP to Odoo ERP: Why You Need Expert Odoo Migration Help February 11, 2026 Posted by: Tony Category: Uncategorized No Comments Why Healthcare Organizations Need Odoo ERP Migration Legacy healthcare ERP systems create barriers to efficiency. They are expensive to maintain, and struggle to integrate tools. This disconnect impacts patient care coordination,

How can we help you?

Get in touch with a solutions consultant that can share best practices and help solve specific challenges.