Why Packaging Companies Are Turning to Odoo For Higher Growth and Improved Efficiency

- December 24, 2025

- Posted by: Tony

- Categories: Blog, Odoo

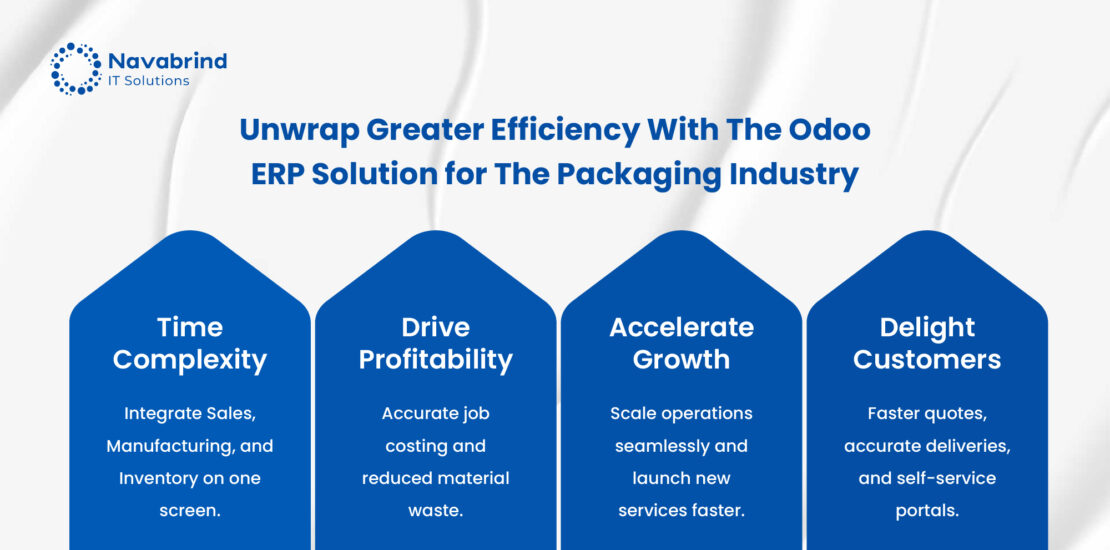

The packaging industry in the USA and Europe stands at a critical crossroads. The sector faces mounting challenges, including volatile raw material and energy prices and increasingly stringent environmental regulations. In Europe, regulations like the Packaging and Packaging Waste Regulation (PPWR) are pushing companies toward sustainability mandates, such as recyclability, use of recycled content, and reduction of single-use plastics. North American packaging companies are grappling with supply chain disruptions, tariff impacts, and shifting consumer priorities towards eco-friendly and smart packaging solutions. These factors are pressuring packaging manufacturers to optimize operations, maintain compliance, and manage costs, all while meeting growing demands for customization and digital engagement.

In this fast-evolving landscape, adopting a modern, integrated ERP system like Odoo ERP is not a luxury but a business imperative. Packaging companies leveraging Odoo ERP gain a centralized platform to streamline production planning, inventory control, quality assurance, and compliance reporting. With its scalable, modular, and open-source design, Odoo empowers packaging firms across sizes—from nimble startups to established enterprises, be it in the USA’s competitive markets or Europe’s regulatory-intensive environment.

Why Odoo ERP Can Help the Packaging Industry

The packaging industry deals with a range of operational complexities that challenge traditional management systems. Custom orders add a layer of complexity, with varying sizes, designs, and specifications that must be handled without error. Accurate inventory management is critical to avoid shortages or overstock.

Beyond materials and production logistics, packaging businesses must comply with strict regulations and sustainability standards, especially in the USA and Europe. Compliance demands detailed traceability, quality assurance processes, and reporting capabilities to satisfy environmental laws and safety standards. These operational intricacies require a technology solution that offers flexibility and real-time visibility to enable efficient workflows.

Packaging firms handle complex production workflows involving multiple steps such as printing, cutting, laminating, and assembling, frequently across several facilities. Coordinating these workflows manually or with disconnected systems leads to bottlenecks at multiple levels. Managing multi-stage production requires advanced planning tools aligned with inventory and quality control systems to optimize resource utilization and ensure reliable product output.

How Odoo’s Flexible, Modular ERP Addresses These Challenges

Odoo ERP is built to address the needs of the packaging industry by offering an integrated, modular platform. Packaging companies can implement core modules for manufacturing, inventory, quality control, procurement, and sales that fit their operational scale and complexity. This modular architecture allows businesses to start with essential functionalities and expand as growth demands, avoiding costly overhauls and unused features.

The flexibility of Odoo ERP extends to customizable workflows that model real-world packaging operations from raw material intake through finished goods delivery. For example, packaging manufacturers can automate multi-level bills of materials (BOMs), s chedule multi-stage routings like printing and laminating, and implement quality checks at each step. Integration with inventory and procurement modules ensures that raw materials are available just in time, reducing waste and improving cost efficiency.

Odoo ERP also excels in supporting regulatory compliance and traceability with built-in batch and lot tracking. Centralized data ensures product specifications remain consistent across sales, production, and customer channels. Its user-friendly dashboards give managers real-time insights to monitor production status, inventory health, and quality outcomes.

Emphasis on Odoo’s Scalability, Customization, and Ease of Use for Packaging Businesses

Scalability is a significant advantage of Odoo ERP for packaging firms of all sizes. Small and mid-sized packaging manufacturers can implement Odoo to bring order and automation to their processes without the need for massive upfront investment. As they grow, Odoo’s modular design enables them to add advanced features such as maintenance scheduling, product lifecycle management, and multi-warehouse management without switching systems or disrupting workflows.

Customization is straightforward since Odoo’s open-source framework enables developers and partners to tailor workflows, reports, and user interfaces to meet packaging requirements. This means packaging companies can automate processes, from custom order configurations to sustainability reporting, that traditional ERP systems either lack or deliver at great cost and complexity.

Ease of use further differentiates Odoo from legacy ERPs. Its intuitive interface reduces training time and increases user adoption across departments, minimizing the resistance and downtime experienced during ERP rollouts. Packaging teams—from production floor operators to planners and sales reps—gain consistent access to real-time, accurate data from a centralized platform, enabling faster decision-making and better coordination. Odoo ERP empowers packaging businesses to reduce costs, improve quality, respond to market shifts swiftly, and position themselves for long-term growth.

Key Odoo Modules and Features Benefiting Packaging Companies

Manufacturing and Production Planning: Managing Multilayered Packaging Production Workflows

Packaging companies manage complex, multilayered production processes—including printing, cutting, laminating, coating, and assembly—that require precise coordination between departments to meet tight delivery schedules. Odoo ERP’s Manufacturing module empowers packaging manufacturers to plan, execute, and monitor production workflows. Companies can create detailed Bills of Materials (BOMs) for multilayered packaging products, track work orders in real time, and optimize machine utilization through advanced scheduling and routing capabilities.

This level of control enables firms to respond dynamically to custom orders and changing demand without causing production bottlenecks. Whether running high-volume corrugated box production or specialized flexible packaging runs, Odoo provides visibility across multiple production stages, helping avoid delays and costly overprocessing. Packaging industry players in the USA and Europe benefit from Odoo’s adaptive production planning that perfectly fits their evolving manufacturing environments and sustainability goals.

Inventory and Warehouse Management: Handling Diverse Raw Materials and Finished Goods with Batch/Serial Tracking

Inventory management in the packaging industry is challenging due to the wide variety of raw material. Odoo ERP’s Inventory module provides robust functionality to track materials across warehouses using batch and serial number tracking, barcode scanning, and automated replenishment triggers. This prevents production delays caused by stockouts and reduces excess inventory carrying costs.

Finished goods and semi-finished products also require tracking as they move through packaging warehouses and distribution networks. Odoo’s multi-warehouse management capabilities allow companies in the packaging industry in the USA and Europe to optimize space utilization and logistics operations, ensuring on-time customer deliveries. Real-time inventory visibility helps managers make smarter procurement decisions and balance supply and demand.

Odoo’s flexible reporting and dashboard tools provide actionable insights into stock aging, turnover rates, and supplier performance, enabling packaging firms to improve overall supply chain efficiency, reduce waste, and maintain regulatory compliance.

Quality Control: Integrated QC to Ensure Compliance and Reduce Defects

Product quality and compliance are key in the packaging industry. Substandard packaging can result in product damage, customer dissatisfaction, or regulatory penalties. Odoo ERP includes an integrated Quality Management module that empowers packaging manufacturers to define, execute, and track quality checks at every stage—from incoming materials, through various production processes, to final inspection.

Automated quality alerts and Non-Conformance Reports (NCRs) streamline the capture and

resolution of defects, and traceability through batch and lot tracking supports root cause analysis and corrective actions. These tools are essential for meeting industry standards and sustainability targets, which are critical in regulated markets like the USA and Europe.

Odoo’s quality control is linked to manufacturing and inventory data, enabling real-time decision-making to prevent defective batches from reaching customers.

Sales and CRM: Managing Client Quotations, Custom Packaging Orders, and Relationship Management

Customized packaging requires close collaboration with customers, from quoting unique specifications to managing approvals and delivery timelines. Odoo ERP integrates Sales and CRM modules to support these complex sales cycles. Packaging companies can generate accurate quotations for tailored orders, track client communications, and manage contract details in a single system.

CRM pipelines ensure sales teams have clear visibility into customer needs and follow-up activities, improving conversion rates and customer satisfaction. Integration with manufacturing and inventory modules enables accurate lead time estimates and on-time delivery commitments.

With Odoo ERP, packaging industry businesses in the USA and Europe foster stronger client relationships and respond quickly to market demands.

Procurement Management: Supplier Management and Just-In-Time Inventory Procurement

Managing suppliers effectively is crucial in the packaging industry, given the diversity and fluctuation of raw materials. Odoo ERP’s Procurement module automates purchase orders, supplier price tracking, and delivery scheduling.

Just-In-Time (JIT) procurement enabled by Odoo ensures materials arrive as needed, freeing up capital and warehouse space. Supplier performance and lead time analytics inform better sourcing decisions and foster close vendor relationships.

Odoo’s integration with inventory and production modules guarantees procurement aligns with manufacturing schedules and customer demand, which is essential for packaging companies in the competitive USA and European markets.

Accounting and Costing: Real-Time Financial Visibility and Cost Accounting for Profitability Analysis

Packaging companies are facing tight margins and volatile input costs. Odoo ERP’s Accounting module provides real-time tracking of production costs, overheads, and procurement expenses to deliver precise cost accounting.

Packaging manufacturers can analyze profitability by product line, order, or production batch, enabling data-driven pricing and budgeting decisions. Integrated financial reporting supports compliance with US GAAP or IFRS and local tax regulations relevant to the packaging industry.

Automated invoicing and payment workflows reduce administrative overhead and accelerate cash flow, and provide visibility into cost variances.

Reporting and Analytics: Tailored Dashboards and Reports for Production Efficiency and Business KPIs

Odoo ERP offers customizable dashboards that collate data across production, inventory, sales, procurement, and finance into actionable insights. Packaging firms can monitor key performance indicators (KPIs) like production throughput, machine utilization, material waste, order cycle times, and customer satisfaction.

Real-time analytics detect bottlenecks and uncover efficiency opportunities. For packaging businesses in Europe and the USA, regulatory productivity and sustainability metrics can be tracked to ensure ongoing compliance and continuous improvement.

Accessible reports improve communication across departments and support executive decision-making, essential for agile responses in a fast-changing packaging market.

Additional Integrations: IoT for Real-Time Production Monitoring, EDI for Supplier and Customer Communication

Odoo ERP supports integration with IoT devices on the production floor, enabling real-time monitoring of machine performance, downtime, and quality parameters in packaging facilities. This connectivity enhances predictive maintenance, reduces unplanned outages, and optimizes resource allocation.

Electronic Data Interchange (EDI) integration facilitates automated, secure communication with suppliers and customers for purchase orders, invoices, shipping notices, and demand forecasts—crucial for synchronized supply chains in packaging operations.

Ideal Business Size and Segments for Odoo Adoption in Packaging

Small to Mid-Sized Packaging Manufacturers Needing Scalable ERP Solutions

Small and mid-sized packaging manufacturers face significant hurdles growing beyond manual or fragmented management systems. As these businesses handle increasing order volumes and diversify product lines, their legacy tools struggle to keep pace. Odoo ERP offers a scalable solution that adapts to evolving operational complexities without overwhelming budgets or requiring massive IT overhead. Packaging companies in the USA and Europe can implement core modules tailored to their pressing needs—such as manufacturing, inventory, and sales—and add functionality as they scale.

This modular approach ensures businesses maintain control over production workflows and benefit from integrated inventory management and quality control. With Odoo ERP, these manufacturers achieve higher visibility, reduce manual errors, and standardize processes, forming a deep foundation for sustainable growth. The accessible cloud and on-premises options also accommodate varying IT maturity levels across small- and mid-sized packaging firms, democratizing ERP benefits and enabling competitive agility.

Beyond managing growth, Odoo’s flexible platform empowers smaller packaging manufacturers to implement industry best practices, such as batch tracing and compliance monitoring, positioning them to meet stricter regulations in the packaging industries.

Growing Enterprises Seeking To Automate Processes and Reduce Manual Errors

As order complexity increases and customer demands for customization intensify. Odoo’s automation capabilities introduce consistency to product lifecycle management, procurement, and production scheduling, freeing teams from repetitive tasks.

Odoo ERP integrates cross-departmental processes, from sales to production and finance, creating a unified data ecosystem that delivers real-time insights and proactive issue resolution. Packaging companies operating multiple production lines and warehouses benefit from robust multi-location management and visibility.

Packaging Service Providers Requiring Integrated Sales, Production, and Supply Chain Management

Packaging service providers offering customized solutions require tight integration between sales quoting, production, and supply chain logistics. Odoo ERP meets this need by connecting CRM, sales, inventory, and manufacturing modules in one cohesive platform. Complex quotations involving custom packaging specifications flow into production schedules, avoiding costly miscommunications that delay deliveries or inflate costs.

The system’s supply chain management features support just-in-time procurement and supplier collaboration, critical for handling diverse materials and fast turnaround projects typical in packaging services. Real-time inventory tracking and batch control ensure that raw materials and finished goods move efficiently through warehouses and production sites, reducing lead times and stock discrepancies.

This integrated approach allows packaging service providers to adapt quickly to client demands, optimize resource utilization, and manage profitability with real-time costing and financial reporting. For service companies in the packaging industry in the USA and Europe.

Large Enterprises Benefiting from Multi-Entity Support and Global Compliance Features

Large packaging enterprises with multinational operations face additional demands related to multi-entity financial consolidation, franchising, and compliance with varying regional laws. Odoo ERP’s architecture supports multiple companies, currencies, languages, and regulatory frameworks, making it an ideal ERP for packaging companies with global footprints.

Multi-entity management streamlines inter-company transactions, centralized procurement, and consolidated financial statements, improving corporate governance. Odoo also supports stringent compliance requirements through batch-level traceability, environmental reporting, and quality certifications. Real-time dashboards aggregate production and financial KPIs across sites, enabling informed executive decision-making and risk mitigation.

For large packaging corporations, Odoo ERP’s cloud-based accessibility and scalability ensure that expansions, acquisitions, or new product lines integrate without disruption. Combined with extensive customization options and a large partner ecosystem, Odoo helps global packaging giants maintain operational excellence.

-

Unified Operations Across the Entire Packaging Value Chain

Packaging businesses often rely on disconnected systems for sales, procurement, production planning, inventory, and quality control. Odoo consolidates all these operations into a single platform, ensuring:

- Consistent data flow across departments

- Fewer manual handovers

- Faster decision-making

- Reduced operational errors

This unified visibility helps packaging manufacturers manage production loads, track order progress, and respond quickly to customer demands.

-

Advanced Bill of Materials (BoM) and Multi-Level Product Configuration

Packaging products—whether folding cartons, labels, corrugated boxes, or custom packaging—require detailed BoMs with multiple layers, materials, and processes.

Odoo supports:

- Multi-level BoMs

- Phantom BoMs for intermediate assemblies

- Product variants and attributes

- Automated material consumption tracking

This enables packaging companies to design complex product structures while avoiding manual recalculations and data duplication.

-

Real-Time Production Planning and Shop Floor Efficiency

Odoo’s manufacturing module gives packaging companies the ability to streamline production with:

- Work center scheduling

- Capacity planning

- Routing optimization

- Machine utilization tracking

- Real-time production progress monitoring

Packaging operations can align machine availability, labor allocation, and order priorities to avoid bottlenecks and maintain on-time delivery.

-

Accurate Costing for Materials, Processes, and Waste Control

Fluctuating raw material costs—paper, plastic resins, adhesives, inks—significantly impact margins. Odoo’s costing engine helps packaging businesses:

- Track material costs in real-time

- Monitor scrap, wastage, and yield

- Compare planned vs. actual production costs

- Create more precise quotations

This transparency improves profitability by enabling data-driven pricing and better control of material waste.

-

Superior Inventory and Warehouse Management

Packaging factories hold high SKU volumes with rapid stock movement. Odoo optimizes inventory through:

- Automated stock replenishment

- Real-time warehouse visibility

- Batch/lot tracking

- Barcode-enabled picking and packing

- FIFO/LIFO management

The result is optimized stock levels, fewer shortages, and lower carrying costs.

-

Integration With Printing & Packaging Machinery

For businesses using digital presses, flexographic machines, die cutters, laminators, or finishing equipment, Odoo can integrate machine data (via IoT box or APIs) to:

- Capture production metrics

- Track downtime

- Monitor machine health

- Improve OEE (Overall Equipment Effectiveness)

This creates a smart manufacturing environment where data flows automatically from machines to Odoo.

-

Strong Quality Control for Materials and Finished Goods

Packaging must meet strict standards for durability, compliance, and visual accuracy. Odoo supports:

- In-process quality checks

- Automated sampling rules

- Defect classification

- NCR and CAPA workflows

- Full traceability from raw material to finished product

This ensures high-quality output and reduces customer returns or rejections.

-

End-to-End Traceability and Compliance Management

Packaging suppliers, especially those serving the food, pharma, and cosmetics industries, must comply with industry regulations. Odoo delivers:

- Complete traceability across lots, batches, and suppliers

- Document control for certifications and approvals

- Audit-ready data logs

This strengthens compliance and simplifies audits or customer inspections.

-

Faster Sales Cycles and Accurate Quotations

Custom packaging often requires rapid quoting, with dynamic pricing based on dimensions, quantity, and materials. Odoo’s integrated tools allow:

- Automated quotation generation

- Real-time material pricing

- Integration with CPQ or pricing matrices

- Customer portal for approval and communication

This shortens turnaround time and increases order conversion rates.

-

Improved Customer Experience Through a Connected Platform

Odoo’s customer portal lets clients:

- Track order status

- View proofs and artwork

- Approve designs

- Download documents

- Communicate changes

This transparency builds trust and strengthens customer relationships.

-

Scalability for Growing Packaging Businesses

Whether a business produces 500 SKUs or 50,000 SKUs, Odoo scales effortlessly with:

- Modular expansion

- Cloud or on-premise deployment

- Custom workflows

- Integration with PIM, DAM, logistics, or e-commerce

Growing packaging companies can add functionalities without replacing their core system.

Leveraging the Large Odoo Partner Network for Packaging Firms

The Odoo ERP ecosystem boasts an extensive partner network that spans regions and industries worldwide. This is a major advantage for packaging companies in the USA and Europe looking to implement or expand their ERP solutions. Specialized partners bring deep knowledge not only of Odoo’s technical capabilities but also of packaging-specific workflows, compliance requirements, and market dynamics. This regional and industry specialization means packaging firms benefit from faster, accurate implementations tailored to their unique needs.

Packaging companies working with expert Odoo partners gain access to customization, integration, and ongoing support services. Certified partners understand the intricacies of managing multilayered production, inventory complexities, and quality control challenges that define the packaging industry USA and Europe. They help firms configure Odoo modules to fit their exact production layouts, automate batch tracking, and align procurement and logistics workflows—all vital for maintaining efficiency and regulatory compliance.

Choosing the certified Odoo partner familiar with the packaging sector reduces risk and enhances ROI. These partners bring proven best practices, templates, and training programs that accelerate user adoption and minimize disruption. Leveraging this global network of knowledgeable partners is a critical success factor for packaging companies aiming to thrive in competitive markets across the USA and Europe.

Why Navabrind IT Solutions is an Ideal Odoo Partner for the Packaging Industry

Navabrind IT Solutions brings deep expertise in Odoo ERP implementations tailored for the manufacturing and packaging sectors. With years of experience working with packaging companies across the USA and Europe, Navabrind IT Solutions understands the operational requirements and compliance challenges faced by this industry. Our team of certified Odoo professionals specializes in optimizing workflows related to multilayered production, inventory management, quality control, and regulatory reporting—ensuring packaging firms get the most out of their ERP investment.

Our proven track record includes a portfolio of successful ERP projects that deliver measurable ROI, helping packaging clients reduce manual effort, minimize waste, and improve product traceability. Navabrind IT Solutions end-to-end service suite covers everything from consultation and solution design to implementation, integration with third-party systems, and ongoing support. This comprehensive approach guarantees that packaging companies leveraging Odoo ERP experience smooth transitions and continuous operational improvements.

What sets Navabrind IT Solutions apart is their commitment to customization and client-centric collaboration. They tailor ERP workflows to meet the precise needs of packaging manufacturers, from custom product configurations to strict compliance adherence in markets like the packaging industry USA and packaging industry Europe. Our dedicated training and support programs maximize user adoption, empowering teams to harness the full capabilities of Odoo ERP. For packaging companies looking for a trusted, knowledgeable partner to guide their digital transformation, Navabrind IT Solutions offers the expertise, responsiveness, and industry focus needed to succeed.

The strategic advantages of adopting Odoo ERP in packaging industry operations

The adoption of Odoo ERP in the packaging industry provides clear and tangible benefits that drive operational excellence and growth. Packaging companies in the USA and Europe realize significant improvements in efficiency because Odoo integrates production planning, inventory management, and quality control into a single platform. This integration reduces waste by ensuring precise raw material usage, timely replenishment, and minimizing errors caused by manual processes and disconnected systems.

Customer satisfaction also improves dramatically with Odoo ERP. The unified system supports faster order turnaround through better scheduling and real-time tracking, enabling companies to meet tight deadlines and exceed client expectations consistently. Enhanced communication tools and accurate product information reduce mistakes and misunderstandings in custom orders, which is challenge in the packaging industry USA and packaging industry Europe.

Beyond immediate operational gains, Odoo ERP helps packaging companies significantly reduce costs. The system provides granular, real-time insights into procurement, production, and sales, allowing managers to identify inefficiencies and optimize spend. Automated financial controls and integrated costing modules reduce accounting errors and streamline budgeting. Odoo’s modular and scalable platform ensures that as packaging companies grow or diversify their product lines, they can easily add new features and customizations without switching systems.

Compliance and quality assurance are non-negotiable in today’s packaging markets, in regulated environments across the USA and Europe. Odoo ERP includes robust quality management tools that integrate into the production workflow, allowing businesses to enforce quality checkpoints and maintain traceability for audits and certification compliance. These features help companies adhere to environmental mandates, safety standards, and industry certifications with confidence.

Frequently Asked Questions

1.What are the best ERP solutions for the packaging industry?

The best ERP solutions for the packaging industry are those that combine flexibility, industry expertise, and scalability to handle the unique demands of packaging manufacturing. Odoo ERP stands out as a top choice in the packaging industry USA and packaging industry Europe due to its modular, integrated platform that covers manufacturing, inventory, quality control, sales, procurement, and financials all in one system. Unlike niche or legacy ERPs, Odoo adapts easily to packaging-specific workflows such as multilayered production, batch tracking, and regulatory compliance. Its open-source foundation encourages customization and rapid deployment, allowing packaging companies to implement the features they need without excess complexity. Odoo’s partner network ensures expert support tailored to regional packaging markets. For packaging firms aiming to streamline operations, reduce errors, and accelerate growth, Odoo ERP delivers a comprehensive, adaptable solution that scales with business needs.Besides all the benefits listed in the above article, here are a few more reasons why Odoo is the best ERP for SMEs.

- User-Friendly Interface: Odoo ensures that SMEs’ employees can learn and work quickly with Odoo ERP.

- Cloud and On-Premise Deployment: Users can choose between a cloud-based and an on-premise solution, giving SMEs the flexibility to deploy the solution they need.

- Support for Digital Transformation: Odoo enables SMEs to automate repetitive tasks, improve data-driven decision-making, and streamline operations, driving deep digital transformation with Odoo ERP across the organization.

- Scalability: Whether an SME is a startup or growing rapidly, Odoo scales easily, ensuring the system can grow alongside the business without needing significant overhauls.

2.How can ERP improve efficiency in packaging manufacturing?

ERP improves efficiency in packaging manufacturing by centralizing and automating critical processes that were traditionally siloed or manual. With Odoo ERP, packaging companies gain full visibility across their production lines, inventory, and supply chain, enabling better planning and real-time tracking. Automated workflows reduce the risk of errors in order processing, materials allocation, and quality inspections, helping avoid costly delays and waste. The integration of sales and manufacturing modules streamlines custom order management—a major efficiency driver in the packaging industry USA and Europe—ensuring customer specifications are accurately translated into production tasks. Additionally, Odoo’s advanced reporting and analytics provide actionable insights that help managers optimize machine utilization, labor allocation, and procurement timing. By improving end-to-end coordination and providing data-driven decision tools, Odoo ERP eliminates bottlenecks and boosts throughput, directly impacting profitability.

3.Which ERP modules are useful for managing packaging production and inventory?

In the packaging industry USA and packaging industry Europe, Odoo ERP offers several key modules that transform production and inventory management. The Manufacturing module lets you map complex, multilayered packaging processes—think printing, laminating, and assembling—with precise control over work orders and scheduling. Inventory management is equally vital; Odoo’s Inventory module handles raw materials like paper rolls and plastics, plus finished goods with batch and serial tracking to maintain traceability and reduce stock errors. Procurement integrates directly, enabling just-in-time purchasing that avoids delays. Connected Sales and CRM modules support managing custom orders and tracking customer requirements. This holistic set of modules gives packaging companies real-time inventory visibility, production efficiency, and process accuracy.

4. How does ERP help with compliance and quality control in packaging?

ERP plays a crucial role in ensuring packaging companies stay compliant and maintain quality standards across operations in the packaging industry in the USA and Europe. Odoo ERP includes an integrated Quality module that embeds checkpoints throughout the production process to catch defects early and automate Non-Conformance Reports (NCRs). Batch and lot traceability lets you fully track materials and finished products for auditing and recalls. The system also streamlines regulatory reporting to comply with evolving environmental and safety standards. By providing a consistent data trail and real-time quality alerts, Odoo ERP prevents defective products from leaving the factory, reduces rework costs, and protects brand reputation.

5.What is the cost and ROI of implementing ERP in a packaging company?

Implementing Odoo ERP in the packaging industry USA and packaging industry Europe is a strategic investment that delivers measurable returns. The upfront cost varies based on the size of the business, scope of modules, and customization needed, but Odoo’s modular nature lets companies control spending by adopting only necessary features initially. Unlike traditional ERP with high licensing fees, Odoo offers cost-effective pricing and flexible deployment options including cloud hosting, reducing infrastructure expenses.

The ROI comes from significant operational efficiencies: reduced manual errors, streamlined production workflows, improved inventory turnover, and better compliance management. Packaging companies see faster order fulfillment, less waste, and improved product quality—all impacting the bottom line positively. With real-time insights for smarter decision-making, these productivity gains pay back the investment within months to a few years.

6. How do packaging companies choose the right ERP implementation partner?

Selecting the right ERP implementation partner in the packaging industry USA and packaging industry Europe is critical to project success. Companies should look for partners with proven expertise in Odoo ERP and a deep understanding of packaging workflows, compliance requirements, and market challenges. Industry knowledge ensures the partner can tailor solutions that address unique packaging needs—like multilayered production, batch tracking, and customization management—without resorting to generic, one-size-fits-all approaches.

An experienced implementation partner like Navabrind IT Solutions, provides end-to-end services: from upfront consultation and precise requirement gathering to customization, integration, user training, and ongoing support. Companies should prioritize certified Odoo partners known for quality delivery and responsive collaboration, as packaging ERP rollouts involve complex change management. Checking references and case studies from similar packaging firms can validate a partner’s effectiveness.

Schedule a conversation with us now!

Related Articles

-

Post

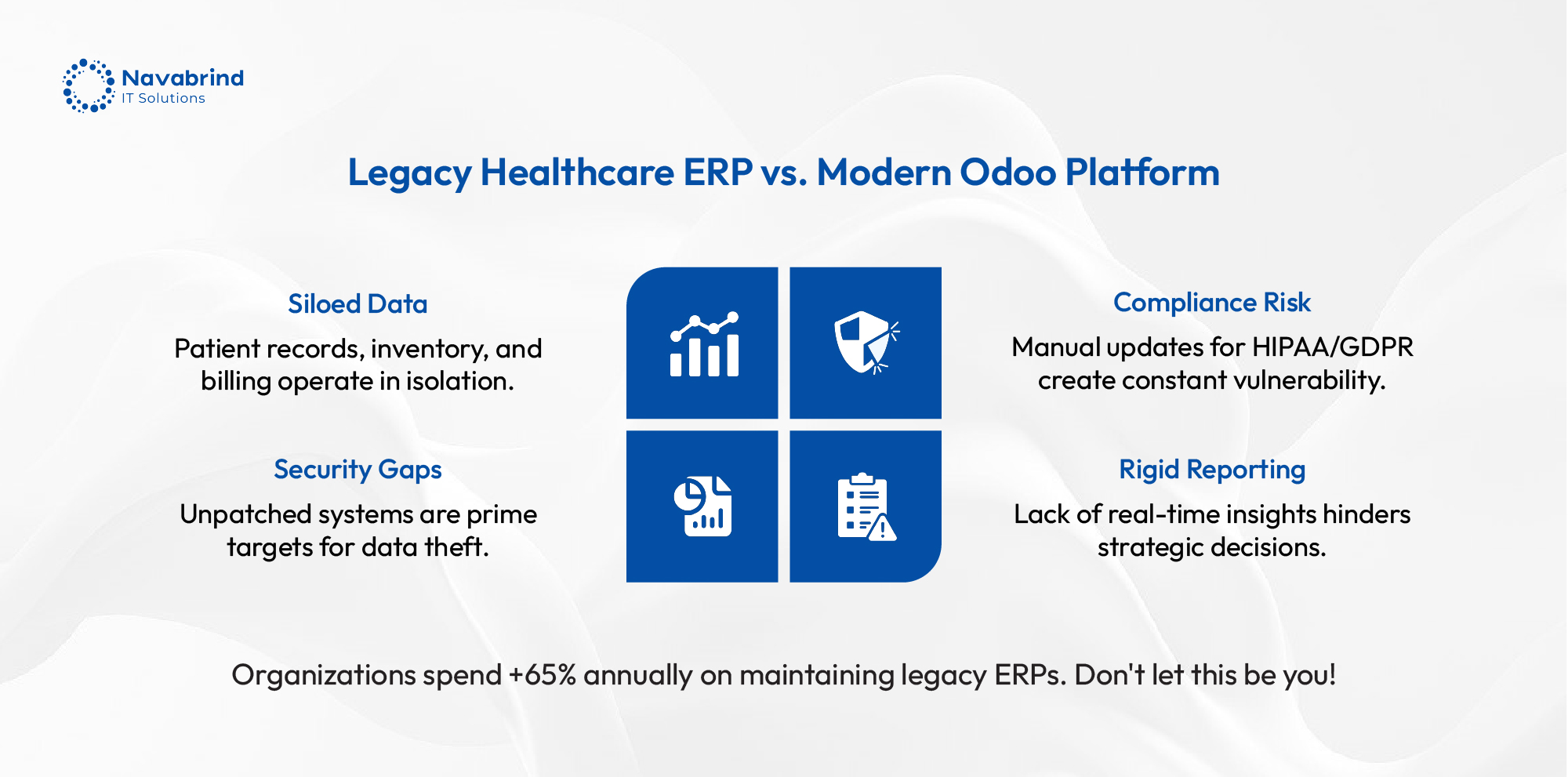

From Legacy Healthcare ERP to Odoo ERP: Why You Need Expert Odoo Migration Help

From Legacy Healthcare ERP to Odoo ERP: Why You Need Expert Odoo Migration Help February 11, 2026 Posted by: Tony Category: Uncategorized No Comments Why Healthcare Organizations Need Odoo ERP Migration Legacy healthcare ERP systems create barriers to efficiency. They are expensive to maintain, and struggle to integrate tools. This disconnect impacts patient care coordination, -

Post

From LLMs to Agentic AI: A Practical Guide to What They Mean and How to Choose

From LLMs to Agentic AI: A Practical Guide to What They Mean and How to Choose February 4, 2026 Posted by: Tony Categories: Artificial Intelligence, Blog No Comments As definitions, use cases, expectations, and investments around Large Language Models (LLMs), Retrieval-Augmented Generation (RAG), AI agents, and agentic AI continue to expand, many individuals and organizations -

Post

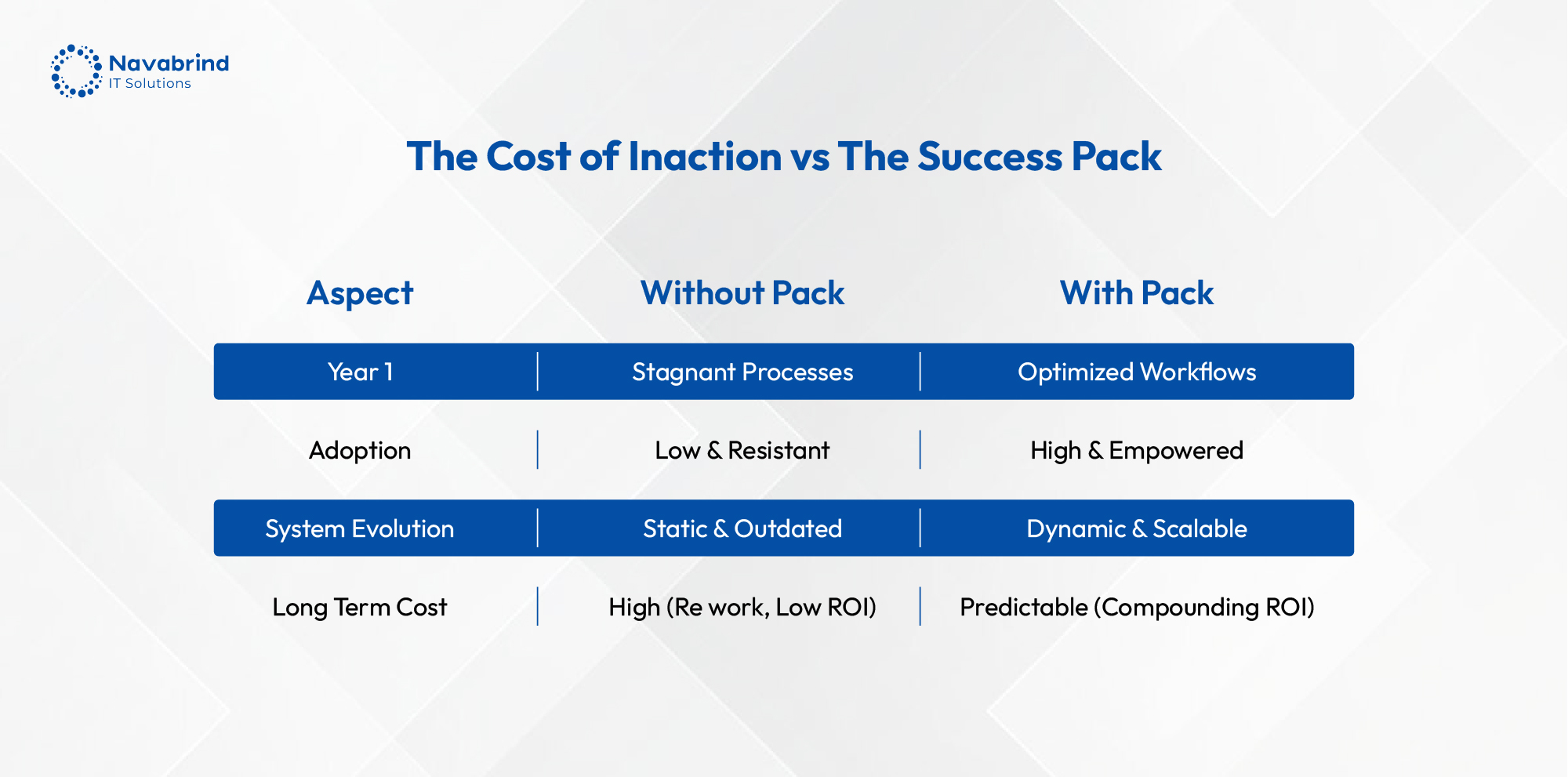

Beyond Go-Live: How Your Odoo Success Pack Drives Real, Long-Term ROI

Beyond Go-Live: How Your Odoo Success Pack Drives Real, Long-Term ROI February 3, 2026 Posted by: Category: Uncategorized No Comments The Implementation Myth Businesses mistakenly measure ERP success by completing the implementation phase while the actual measure of value is the operational transformation unlocked after go-live. The Odoo Success Pack is the framework engineered to

How can we help you?

Get in touch with a solutions consultant that can share best practices and help solve specific challenges.