Revealing Odoo Implementation Methodologies for the Electronics Industry

- June 24, 2025

- Posted by: Jaishree Jayabal Singh

- Categories: Blog, Odoo

The electronics industry is known for its complex supply chains, high-mix low-volume production models, strict compliance standards, and ever-evolving product life cycles. For manufacturers and distributors in this space, the right ERP solution must offer flexibility, real-time visibility, and scalability. That’s where Odoo ERP for Electronics Industry stands out, offering a modular platform capable of adapting to the nuanced workflows of electronics companies.

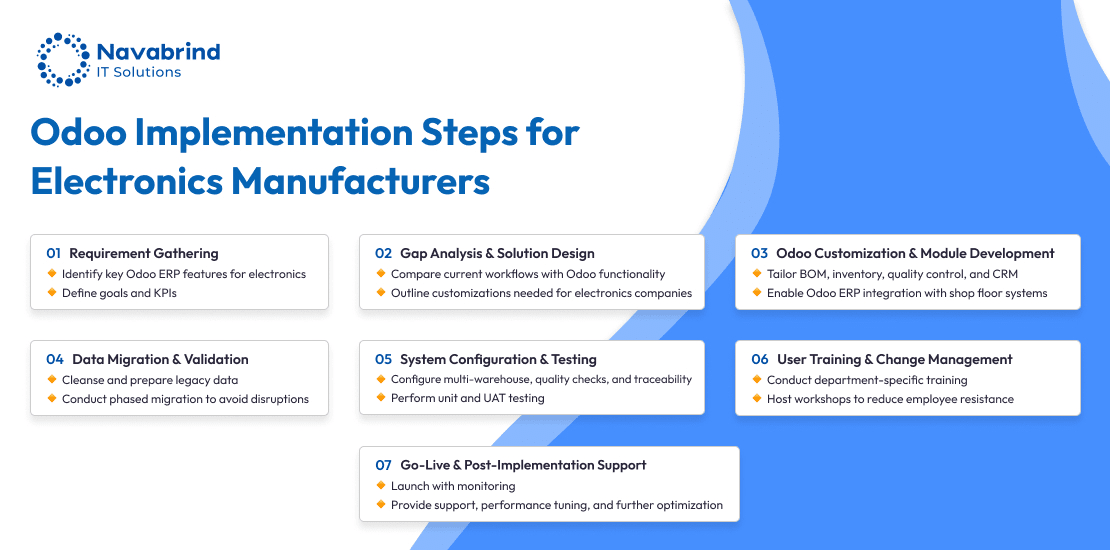

But choosing the right software is only the beginning. The success of Odoo implementation in electronics manufacturing hinges on the methodology behind the deployment. A structured, phase-wise implementation guided by industry best practices minimizes risks and ensures business continuity. From requirement analysis and data migration to module customization and user training, each step must be precisely executed—especially in an industry where downtime and data errors can be costly.

In this blog, we’ll reveal proven Odoo ERP implementation strategies tailored for the electronics sector. You’ll learn how expert Odoo consultants USA apply best practices, manage challenges, and leverage the platform’s full potential through disciplined project execution. Whether you’re a component manufacturer, OEM, or electronics distributor, understanding the right methodology can be the difference between a delayed project and a digital success story.

Key Pain Points in Electronics Manufacturing

Electronics manufacturing presents unique operational complexities that traditional ERP systems often fail to address effectively:

- Complex BOM (Bill of Materials) Management

Products typically consist of multiple components sourced globally, requiring precise version control, change tracking, and cost management. - Multi-Level Supply Chain Tracking

With global suppliers and logistics partners, maintaining visibility across all nodes in the supply chain becomes critical. - Compliance & Quality Control Demands

Regulatory standards (such as RoHS, REACH, and ISO) require traceability, documentation, and consistent quality checks. - High-Mix, Low-Volume Production Challenges

Electronics companies often produce a wide variety of SKUs in smaller batches, increasing complexity in scheduling, inventory, and changeovers.

How Odoo ERP Solves These Issues

Odoo ERP implementation in electronics manufacturing is tailored to provide comprehensive operational visibility and automation. It addresses the sector’s unique challenges by offering targeted solutions that optimize production, inventory, quality, and compliance processes.

Real-Time Inventory & Procurement Tracking

Odoo’s robust inventory module enables manufacturers to manage multi-warehouse operations with real-time stock tracking and automated procurement rules. Electronics companies benefit from just-in-time inventory management, integration with vendor portals for seamless reordering, and real-time visibility into raw materials and finished goods. These Odoo ERP features for electronics help reduce stock-outs and excess inventory while improving cash flow and delivery timelines.

Automated BOM & Work Order Management

Managing complex Bills of Materials is a critical need in electronics manufacturing. Odoo supports multi-level BOM hierarchies, dynamic updates with full revision history, and automatic generation of work orders and routing instructions. With Odoo customization for the electronics industry, manufacturers can keep their production aligned with engineering changes, eliminate manual data entry, and streamline the production lifecycle from planning to execution.

Quality Control & Traceability Modules

Compliance and traceability are non-negotiable in the electronics sector. Odoo’s quality management tools provide quality checks at every stage of production, along with lot and serial number tracking and non-conformance handling. These capabilities align with industry regulations and give companies the ability to trace defects or failures back to their source—an essential feature for audits and improving product quality.

Seamless Integration with IoT & Smart Manufacturing

Odoo ERP supports integration with IoT-enabled devices, barcode scanners, and smart shop floor systems. This enables real-time monitoring of equipment performance, delivery of digital work instructions, and predictive maintenance planning. These smart manufacturing features enhance overall equipment effectiveness (OEE) and bridge the gap between IT and OT systems in electronics production environments. With Odoo ERP integration USA, companies can digitize their operations and drive data-driven improvements on the shop floor.

Why Odoo Stands Out for Electronics Manufacturers

The breadth and depth of features in Odoo make it the best ERP for electronics manufacturers USA, particularly for companies seeking a cost-effective, scalable, and fully integrated solution. As an open-source platform, Odoo allows for deep customization and seamless integration with third-party tools like CAD systems, PLM, and IoT devices—ideal for digital transformation in electronics manufacturing.

By following a proven Odoo project methodology, businesses can ensure a smooth transition from legacy systems to a unified platform that supports continuous improvement, real-time decision-making, and long-term growth.

To get the most from your ERP journey, partner with an experienced Odoo Partner USA who understands the industry, offers tailored Odoo implementation steps for electronics, and provides ongoing support for enhancements and upgrades.

Challenges in implementing Odoo ERP in electronics industry and how to solve them

While Odoo ERP for Electronics Industry offers powerful tools to modernize operations, the path to successful implementation can come with hurdles. Electronics manufacturers often encounter common challenges that, if not addressed proactively, can derail timelines and affect adoption. Recognizing these roadblocks and planning solutions in advance is critical for the success of Odoo Implementation in Electronics Manufacturing.

Common Roadblocks in Odoo ERP Deployment

- Resistance to Change from Employees

One of the most frequent issues in ERP rollouts is employee pushback. Staff may fear added complexity or disruption to familiar processes, especially in electronics firms where precision and speed are non-negotiable. - Data Migration Complexities

Migrating data from legacy systems into Odoo ERP USA can be time-consuming and error-prone. The electronics sector, with its multi-tiered BOMs, inventory codes, and serialized components, makes clean, accurate data migration even more essential. - Customization Delays

While Odoo customization for the electronics industry offers high flexibility, over-customization or poor planning can result in delays. Misaligned expectations or vague requirements often lead to development bottlenecks.

Proven Solutions with the Right Approach

Working with an experienced Odoo Partner USA can help navigate these obstacles efficiently. Here’s how:

- Effective Change Management Strategies

Structured change management—including employee training, process documentation, and interactive workshops—helps teams understand and embrace the transition. Odoo consultants USA often implement phased rollouts and user acceptance testing to build confidence and reduce friction. - Phased Data Migration Approach

Rather than migrating all systems at once, a phased strategy that starts with critical modules like Inventory or Production reduces risk. This stepwise approach aligns with the best Odoo implementation steps for electronics, ensuring smoother onboarding and minimal downtime. - Clear Scope and Agile Customization

Adopting modular implementation and iterative development—key principles in Odoo project methodology—helps reduce delays and improves time-to-value. By prioritizing key Odoo ERP features for electronics, manufacturers can go live quickly and evolve the system as needed.

Choosing the Right Partner for Odoo ERP Implementation

Implementing an ERP system in electronics manufacturing is a strategic transformation, not just a technology upgrade. Partnering with the right Odoo Partner USA ensures success through deep industry expertise, tailored configuration of Odoo modules, and comprehensive support for each stage of deployment. This includes requirements gathering, customization, data migration, user training, and go-live. Trusted Odoo consultants USA also bring a proven Odoo project methodology, helping manufacturers adopt the system efficiently while minimizing disruption.

Unlike traditional ERPs that come with high upfront costs and lengthy deployment timelines, Odoo ERP USA offers a modular, scalable solution that fits businesses of all sizes. Organizations can choose to implement only the modules they need, with the flexibility of cloud or on-premise deployment. Odoo also integrates easily with third-party tools such as CAD systems and PLM platforms. These features make Odoo the best ERP for electronics manufacturers in the USA, whether you’re a growing startup or an established OEM serving global markets.

Choosing the Right Odoo Partner in the USA

Successfully adopting Odoo ERP for the Electronics Industry goes beyond just selecting the right software—it requires partnering with the right implementation expert. The electronics manufacturing sector has unique challenges such as multi-level BOMs, stringent quality requirements, and complex supply chains. To fully unlock the potential of Odoo ERP USA, it’s essential to work with an experienced and reliable Odoo Partner USA who understands the intricacies of your industry and tailors the system accordingly.

Why Work with an Odoo Certified Partner?

Choosing an Odoo Gold Partner ensures you’re working with a team that has demonstrated proven technical capabilities, extensive project experience, and direct collaboration with Odoo S.A. These partners offer distinct advantages, especially for Odoo Implementation in Electronics Manufacturing:

- Industry-Specific Expertise in Electronics Manufacturing

A seasoned partner brings domain knowledge of electronics manufacturing ERP solutions, including processes like component-level traceability, production scheduling, and compliance reporting. They understand the critical Odoo ERP features for electronics and can guide you through use cases relevant to your business. - Faster Implementation with Pre-Configured Templates

Gold partners often come equipped with pre-built templates and workflows designed for Odoo customization for electronics industry needs. This accelerates deployment and minimizes disruption while ensuring adherence to best practices in Odoo ERP implementation strategies. - Ongoing Support & Customization

Post-implementation support is vital. Whether it’s enhancing the system with new modules, fine-tuning workflows, or managing upgrades, a trusted partner provides long-term value through ongoing improvements. This includes assistance with Odoo ERP integration USA and aligning the ERP system with emerging technologies like IoT, PLM, or MES platforms.

Questions to Ask Before Hiring an Odoo Consultant

Before choosing among the many Odoo consultants in the USA, electronics companies should evaluate potential partners based on their methodology, technical expertise, and industry familiarity. Consider asking:

- Have you worked with electronics manufacturers before?

Prior experience with electronics firms ensures the consultant understands your operational challenges and regulatory requirements. It also indicates familiarity with relevant Odoo implementation steps for electronics, such as handling serialized components or configuring RMA processes. - What is your approach to data migration & integration?

Data is the foundation of any ERP. A reliable consultant should demonstrate a structured approach to data cleansing, legacy system integration, and third-party tool connectivity. This is essential for ensuring smooth transition and alignment with the overall Odoo project methodology. - Do you provide post-go-live support?

Implementation is just the beginning. Post-go-live support ensures your team gets the help they need during adoption, and that the system evolves with your business. Whether it’s training, reporting enhancements, or ongoing module additions, this support is key to realizing the full ROI from ERP software for electronics business.

Partnering for Long-Term Success

Odoo’s modular, scalable architecture makes it the best ERP for electronics manufacturers in the USA—but only when implemented thoughtfully. A capable Odoo Partner USA not only speeds up deployment but also ensures the ERP aligns with your business strategy. From configuring complex BOMs to integrating with IoT and quality control systems, the right partner helps you extract the most value from Odoo for electronics companies.

Take the time to vet your consultant, align on goals, and ensure their approach fits your vision. With the right guidance, Odoo Implementation in Electronics Manufacturing can be a strategic move that drives operational efficiency, digital transformation, and long-term growth.

Many of these challenges can be effectively mitigated by collaborating with the right Odoo consultants USA who specialize in electronics manufacturing ERP solutions. These experts offer tailored Odoo ERP implementation strategies, helping you align technology with business outcomes while ensuring compliance, scalability, and efficiency.

Ultimately, successful Odoo ERP integration USA depends on preparation, communication, and expert guidance. Whether you’re a growing component supplier or an established OEM, proactive planning with a trusted Odoo Partner USA ensures that your ERP journey supports—not disrupts—your operations.

Frequently Asked Questions

1. How to Implement Odoo ERP in Electronics Manufacturing Companies in the USA

Implementing Odoo ERP for Electronics Industry in U.S.-based electronics manufacturing companies begins with a thorough needs assessment. This phase focuses on mapping business processes, identifying inefficiencies, and understanding specific operational pain points such as complex BOM structures, inventory traceability, and quality control workflows. Collaborating with an experienced Odoo Partner USA ensures that the platform is aligned with the company’s strategic goals and regulatory environment. The goal is to define the scope of the Odoo implementation steps for electronics, starting with core areas like production, inventory, and procurement.

Once the scope is defined, the next step is configuration and customization. Electronics manufacturing often requires tailored workflows—such as multi-level BOMs, serial number tracking, or integration with CAD and IoT devices. With expert guidance from Odoo consultants USA, businesses can leverage relevant Odoo ERP features for electronics while introducing targeted enhancements through Odoo customization for the electronics industry. This stage also involves configuring Odoo ERP integration USA with third-party systems like PLM, MES, and vendor portals, ensuring a connected and intelligent ecosystem.

After configuration, a phased rollout is recommended using agile Odoo project methodology. Begin with pilot modules such as Inventory or Manufacturing, validate performance, then scale across Sales, Finance, and CRM. Training and user adoption play a crucial role—conduct workshops, create process documentation, and provide ongoing support to build internal confidence. By following this structured path and working with a proven Odoo Partner USA, electronics companies can ensure a smooth transition to a scalable, modern ERP software for electronics business, driving long-term efficiency and growth.

2. What is the Best Odoo ERP Implementation Methodology for the Electronics Industry in 2025?

The best Odoo ERP implementation methodology for the electronics industry in 2025 is a hybrid approach that combines agile principles with electronics-specific process templates. Electronics manufacturing is dynamic, requiring flexible ERP rollouts that can adapt to shifting product life cycles, compliance standards, and customer-specific requirements. Leading Odoo consultants USA now use modular deployment strategies—beginning with foundational modules such as Inventory and Manufacturing—before expanding to more advanced areas like Quality Management, CRM, and Procurement. This staged delivery ensures minimal disruption and faster ROI.

This methodology starts with discovery workshops to capture business objectives and system requirements, followed by gap analysis and solution design tailored for Odoo ERP for the Electronics Industry. The use of industry accelerators and pre-configured templates provided by a qualified Odoo Partner USA can significantly shorten the implementation timeline. Integration with hardware and software components—such as IoT, barcode scanners, and PLM systems—is handled using a plug-and-play approach supported by best-in-class Odoo ERP integration USA practices. Such strategies ensure end-to-end connectivity and operational visibility for Odoo for Electronics Companies.

Critical to this methodology is continuous feedback and iteration. Every stage includes validation, user testing, and change management support to increase adoption. Using this agile framework, Odoo ERP USA deployments are broken into sprints that deliver value incrementally. This also allows for adaptive Odoo customization for the electronics industry based on evolving business needs. In 2025, the most effective ERP deployments will not only automate workflows but also deliver strategic insights and compliance-ready operations—making this approach ideal for companies seeking the best ERP for electronics manufacturers in the USA.

3. Are there custom Odoo ERP solutions for US-based electronics companies?

Yes, there are highly tailored Odoo ERP solutions for electronics companies in the United States, specifically designed to address the unique challenges of this fast-paced and innovation-driven industry. Whether it’s managing complex BOMs, handling high-mix, low-volume production, or tracking serial numbers and regulatory compliance, Odoo ERP for Electronics Industry offers a robust and flexible foundation. These solutions are often delivered by an Odoo Partner USA who understands the nuances of electronics manufacturing and can implement the platform in a way that aligns with business objectives.

Odoo customization for the electronics industry is a critical element of these tailored solutions. It includes fine-tuning modules like Inventory, Manufacturing, Quality Management, and Procurement to support industry-specific workflows such as dynamic BOM management, IoT-enabled production monitoring, and vendor traceability. U.S.-based electronics manufacturers often require Odoo ERP integration USA with third-party platforms such as PLM, CAD systems, or testing equipment. These integrations are handled through specialized connectors and APIs, ensuring seamless data exchange and real-time visibility across departments.

By leveraging the right Odoo ERP implementation strategies, businesses in the electronics space can benefit from agile, phased rollouts with full transparency. Odoo consultants USA often use an industry-adapted Odoo project methodology, involving discovery workshops, configuration, UAT, and go-live support. This ensures that the ERP system not only fits the electronics domain but also scales as the business grows. The result is a flexible, cost-effective ERP software for electronics business that delivers high ROI, regulatory readiness, and long-term process efficiency.

4. Where can I find affordable Odoo ERP implementation services for electronics in the USA?

Finding affordable yet reliable Odoo Implementation in Electronics Manufacturing is crucial for small to mid-sized U.S. electronics companies looking to digitize operations without overspending. The most effective approach is to work with a certified Odoo Partner USA that offers scalable packages tailored for the electronics industry. These partners often provide pre-configured templates, reusable components, and industry accelerators that reduce both the time and cost of implementation. This allows businesses to access enterprise-grade Odoo ERP features for electronics without exceeding budget constraints.

Several Odoo consultants USA specialize in providing cost-effective solutions by employing lean project delivery models. These consultants focus on critical Odoo implementation steps for electronics, such as process mapping, core module deployment, and user training—often within a fixed-scope framework. Choosing a phased implementation approach also helps businesses spread costs while ensuring each module delivers tangible value before scaling. In many cases, initial deployment begins with Inventory, Procurement, and Manufacturing, followed by CRM, Quality, and Finance.

In 2025, the best strategy for affordable ERP deployment involves leveraging cloud-based Odoo ERP USA installations with limited upfront infrastructure investments. These setups are ideal for manufacturers who want flexibility, lower total cost of ownership, and access to real-time insights. By working with an experienced Odoo partner offering proven Odoo ERP implementation strategies and transparent pricing, U.S. electronics manufacturers can unlock the benefits of the best ERP for electronics manufacturers USA—including automation, traceability, and smarter decision-making—at a price point that aligns with their growth trajectory.

5. How do I identify an Odoo implementation partner for electronics companies in the USA?

Identifying the right Odoo Partner USA for your electronics business begins with evaluating the partner’s industry experience and technical capabilities. Look for firms that have a proven track record of Odoo Implementation in Electronics Manufacturing and understand the challenges of the sector—such as complex supply chains, component traceability, and frequent engineering changes. A reliable partner should demonstrate familiarity with core Odoo ERP features for electronics, including modules for manufacturing, quality control, inventory, procurement, and sales.

Another critical factor is the partner’s approach to Odoo ERP implementation strategies. A qualified firm will clearly outline their Odoo project methodology, which should include requirement gathering, business process mapping, module configuration, integration planning, and user training. Ask potential Odoo consultants USA about their experience with data migration, third-party Odoo ERP integration USA, and whether they provide post-go-live support. Partners who follow structured Odoo implementation steps for electronics are better equipped to manage risk and deliver on time and budget.

Lastly, consider scalability and support. The best ERP for electronics manufacturers USA is not a one-time installation, but an evolving platform. Ensure your implementation partner offers long-term support, Odoo customization for the electronics industry, and the ability to adapt your system as your product lines, compliance needs, or customer base changes. When working with an experienced Odoo partner, you get not just technical deployment, but a strategic advisor who can help future-proof your ERP software for electronics business.

6. Why choose Odoo ERP for your electronics manufacturing business in 2025?

As the electronics industry faces increasing pressure from global supply chain disruptions, tighter compliance regulations, and rising customer expectations, Odoo ERP for Electronics Industry stands out as a modern, integrated, and agile solution. In 2025, manufacturers require real-time visibility across operations, and Odoo ERP USA delivers exactly that—with features spanning inventory management, multi-level BOMs, quality assurance, and shop floor control. Unlike traditional systems, Odoo is modular, cost-effective, and designed to grow with your business.

One of the key advantages of Odoo for electronics companies is its ability to handle high-mix, low-volume production with ease. Through tailored Odoo ERP implementation strategies, manufacturers can align production with engineering changes, manage serialized components, and monitor performance in real-time. The platform also offers seamless Odoo ERP integration USA with PLM, CAD, IoT devices, and other third-party systems—making it ideal for digital-first manufacturers. Features like RMA tracking, customer-specific pricing, and vendor portal access further enhance its value for the electronics sector.

Additionally, Odoo’s adaptability is a game changer in 2025. Whether you’re a startup assembling smart devices or a large OEM managing hundreds of components, Odoo customization for the electronics industry enables your ERP to reflect your workflows. Supported by certified Odoo consultants USA, companies can implement step-by-step using a proven Odoo project methodology—starting with core functions and expanding as needed. This flexibility, combined with affordability and robust functionality, makes Odoo the best ERP for electronics manufacturers in the USA, empowering them to compete globally with confidence and speed.

7. What is Odoo ERP deployment timeline for electronics manufacturers?

The Odoo ERP deployment timeline for electronics manufacturers typically ranges from 12 to 24 weeks, depending on the complexity of operations and customization needs. For most electronics manufacturing ERP solutions, the timeline includes several defined stages: requirement analysis, system configuration, development/customization, data migration, testing, training, and go-live. When working with an experienced Odoo Partner USA, the process becomes smoother due to their knowledge of industry workflows and ability to align Odoo ERP features for electronics with specific business objectives. This timeline can be shortened if pre-configured templates are used and if the electronics company has a clear understanding of their internal processes.

A phased implementation using proven Odoo ERP implementation strategies helps reduce risk and ensures steady progress. The initial 2–3 weeks are typically dedicated to requirements gathering and solution mapping. This is followed by 6–8 weeks of configuration and customization, especially important for Odoo customization for electronics industry needs such as complex BOMs, quality control checkpoints, and traceability functions. Subsequent weeks focus on Odoo ERP integration USA with external systems (like PLM, IoT platforms, or CAD tools), data migration from legacy systems, and iterative testing. These Odoo implementation steps for electronics are essential to minimize errors and optimize system performance before going live.

It’s worth noting that Odoo ERP USA provides flexibility in deployment—either as a big bang or a modular rollout. A modular approach is often preferred for Odoo for electronics companies, as it allows teams to adapt gradually and reduces downtime. Additionally, Odoo consultants USA emphasize the importance of post-deployment support, system tuning, and user feedback loops as part of the extended deployment lifecycle. With the right Odoo project methodology and by working with an experienced Odoo partner, companies can meet their go-live targets and set the foundation for scalable, efficient operations—making Odoo the best ERP for electronics manufacturers in the USA seeking agility and long-term ROI.

Schedule a conversation with us now!

Related Articles

-

Post

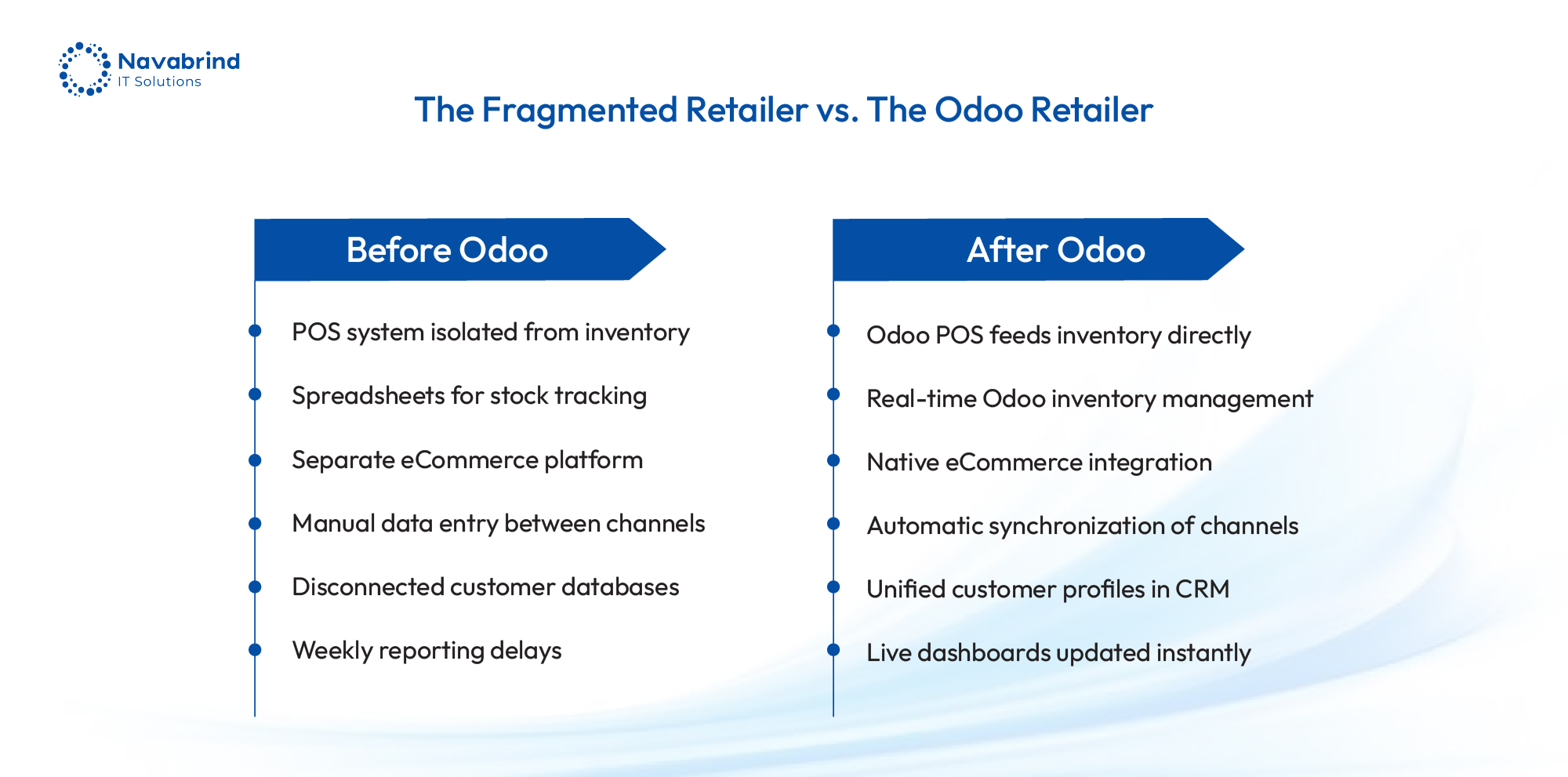

Odoo ERP for the Retail Industry: Driving Efficiency and Growth

Odoo ERP for the Retail Industry: Driving Efficiency and Growth February 27, 2026 Posted by: Vasanth Anantharaman Categories: Blog, Odoo for Retail industry No Comments Why the Retail Industry Runs Better on Odoo ERP Retail runs on dozens of disconnected apps. One tool for sales, another for stock, a third for loyalty. None speak to -

Post

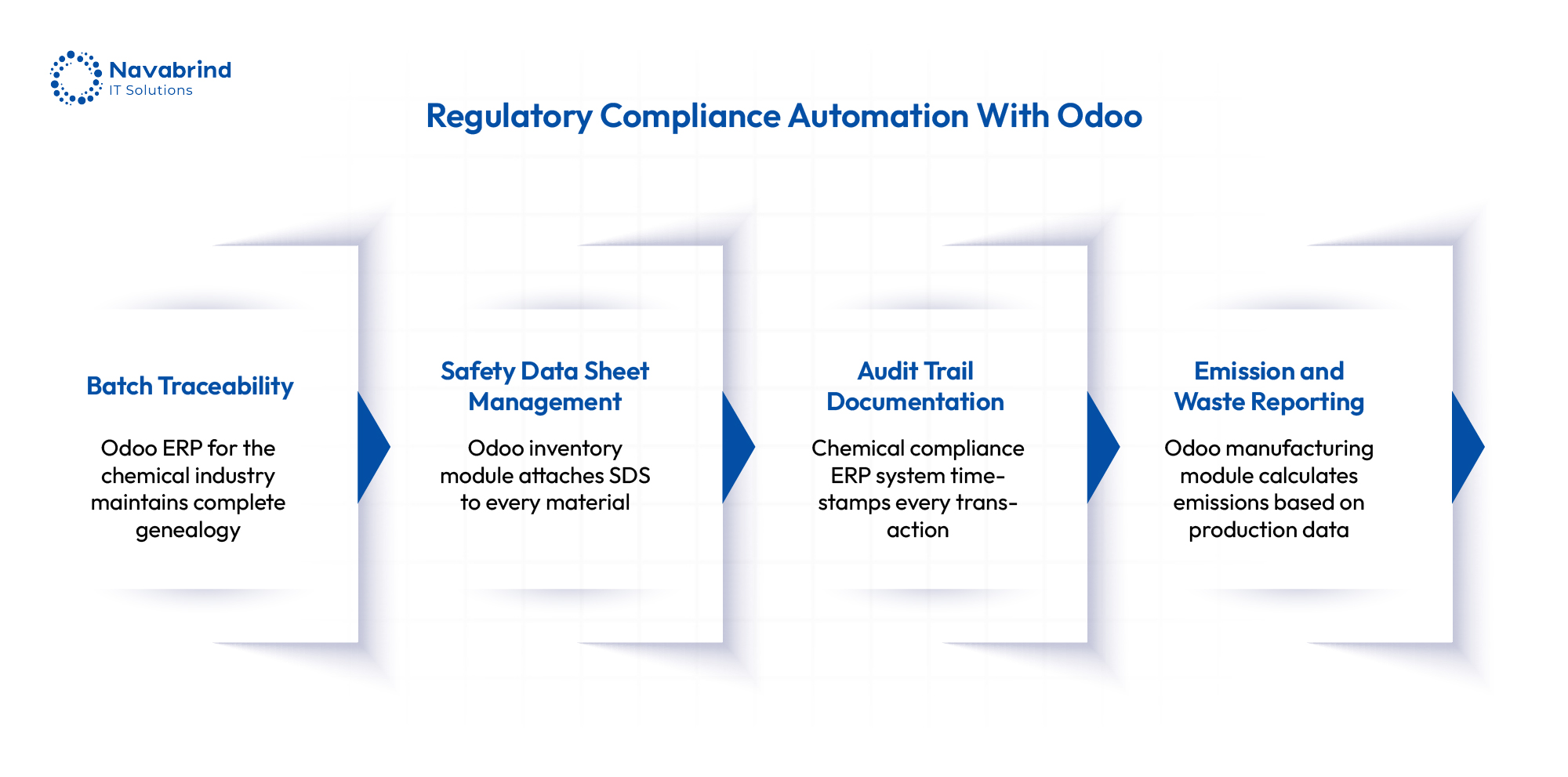

From Formula to Forecast: Odoo’s Transformative Edge in Chemical Manufacturing

From Formula to Forecast: Odoo’s Transformative Edge in Chemical Manufacturing February 27, 2026 Posted by: Jaishree Jayabal Singh Categories: Blog, Odoo ERP for Chemical Industry No Comments Odoo ERP for Chemical Industry Solves the Disconnection Problem Chemical manufacturing operates across multiple fronts, production floors, warehouse storage, laboratory testing, and regulatory reporting. Managing these as isolated -

Post

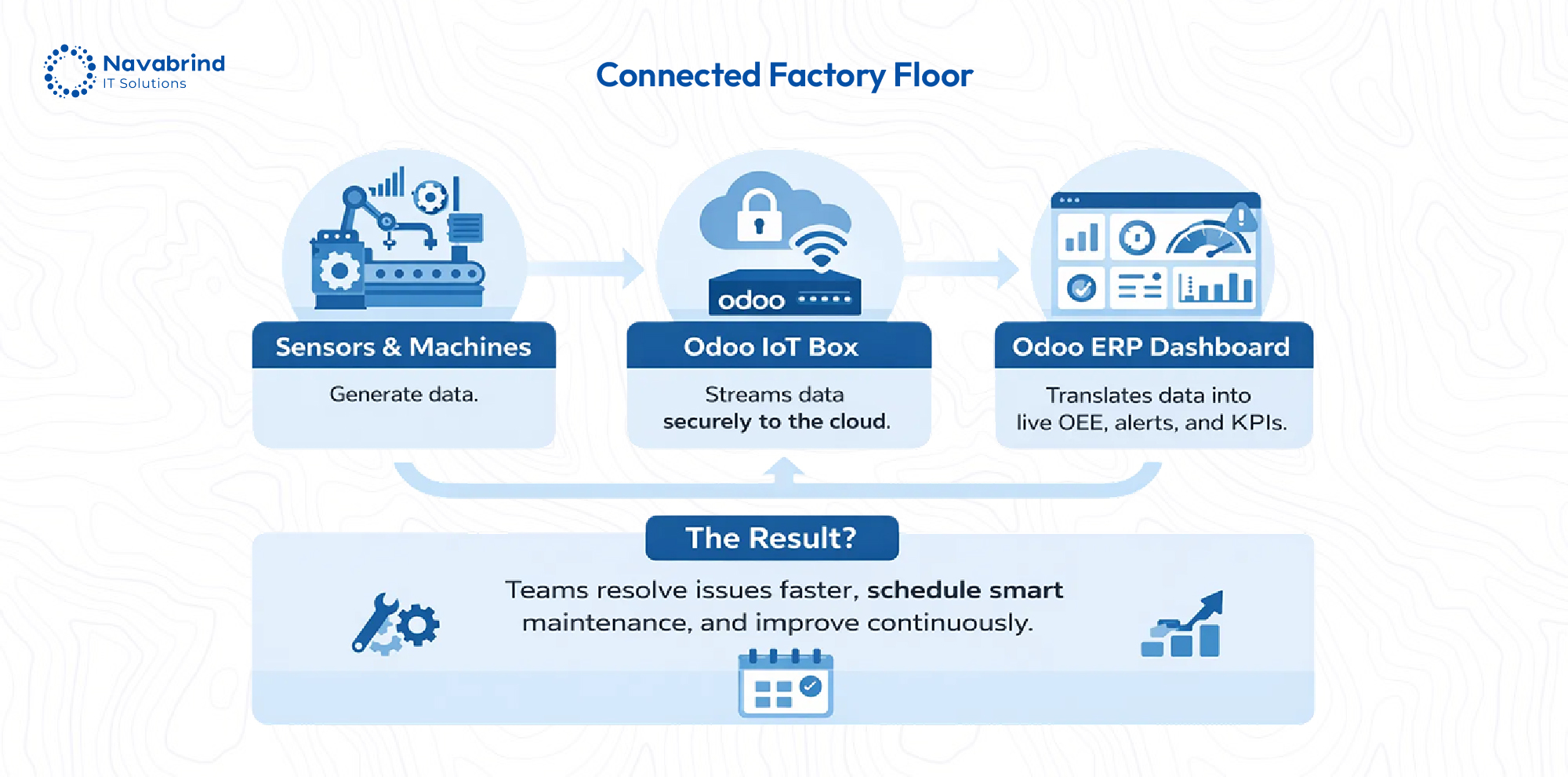

How Odoo ERP Helps Manufacturers Track Machine Efficiency and Move Toward Industry 4.0

How Odoo ERP Helps Manufacturers Track Machine Efficiency and Move Toward Industry 4.0 February 25, 2026 Posted by: Venkadesh Nagarajan Category: Uncategorized No Comments The Shift Toward Smart Manufacturing Machine efficiency is the core of manufacturing. Without it, cost control and scalability are impossible. Industry 4.0 accelerates this, merging IoT and data analytics to drive

How can we help you?

Get in touch with a solutions consultant that can share best practices and help solve specific challenges.