Odoo ERP Modules Every Manufacturing Business Should Consider

- May 21, 2025

- Posted by: Tony

- Categories: Blog, Odoo Manufacturing

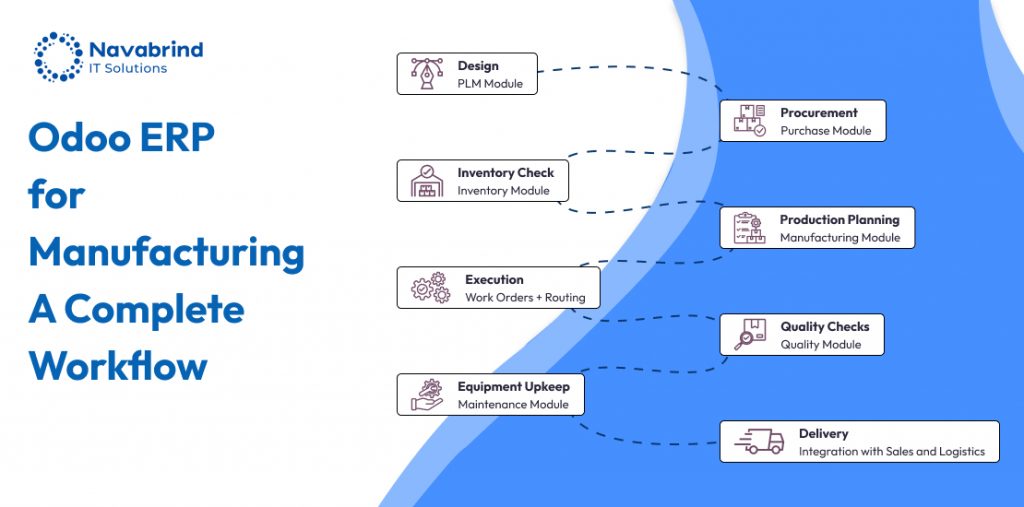

Odoo for manufacturing stands out as a powerful, modular ERP platform tailored to the needs of enterprises across industries. With its flexible and scalable architecture, Odoo ERP solutions offer businesses the ability to start with the basics and expand functionalities as operations grow. Whether it’s production scheduling, inventory management, equipment maintenance, or product lifecycle management, Odoo manufacturing ERP provides end-to-end visibility and control. By leveraging the right combination of Odoo ERP modules, manufacturers can automate workflows, monitor key performance indicators in real-time, and make faster, data-driven decisions.

This blog explores the best Odoo modules for manufacturers, focusing on the essential ERP modules for factories that deliver measurable results. From Odoo inventory and MRP modules to advanced Odoo apps for production, we’ll highlight the must-have Odoo ERP modules for manufacturing companies. You’ll discover top Odoo modules to streamline production and inventory, understand how Odoo helps manufacturers manage operations, and learn about the key ERP tools in Odoo for manufacturing success.

Why ERP Is Essential for Modern Manufacturing Competitiveness

Manufacturing businesses operate under constant pressure to improve speed, efficiency, and cost-effectiveness. Yet many factories continue to rely on fragmented systems—legacy software, spreadsheets, and manual processes—that operate in silos. These disconnected tools hinder visibility across departments, delay production timelines, cause inventory inaccuracies, and create operational bottlenecks. As manufacturing becomes more data-driven and complex, the inability to access real-time insights becomes a critical liability.

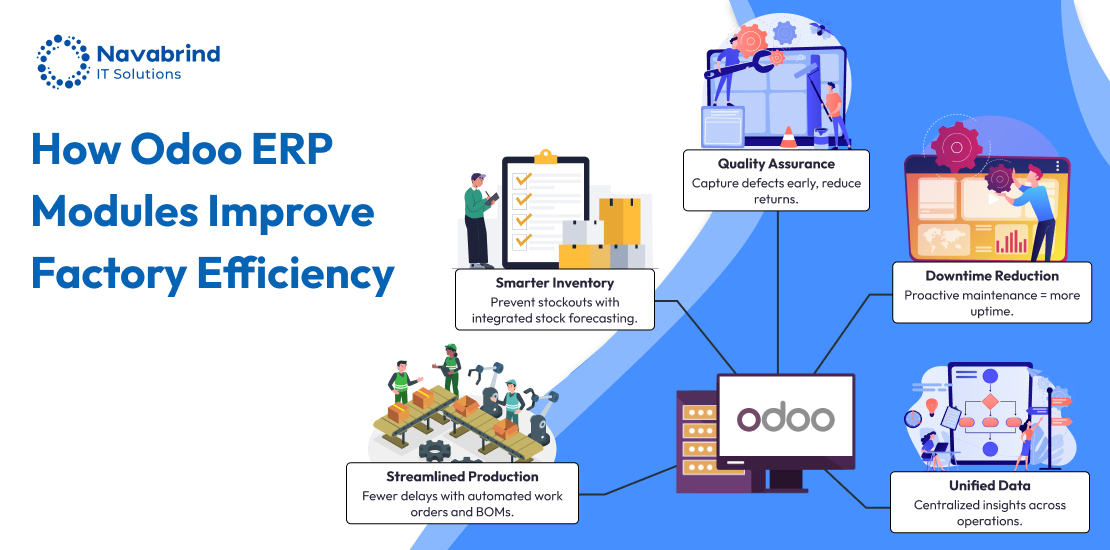

An integrated ERP for manufacturing business is no longer a luxury—it’s a strategic necessity. ERP systems consolidate operations, unify data flows, and provide a single source of truth across production, inventory, procurement, and quality. This integration empowers manufacturers to reduce errors, improve lead times, automate repetitive tasks, and increase overall responsiveness to market demands. In a landscape where agility and precision define competitiveness, ERP systems are foundational to achieving scalable, sustainable growth.

Odoo for manufacturing offers a future-ready solution with its modular and customizable architecture. Businesses can deploy only the Odoo ERP modules they need—such as Inventory, MRP, Maintenance, Quality, and PLM—and scale as operations expand. The platform is designed to support real-time shop floor management, efficient inventory planning, and predictive maintenance, all under one ecosystem. These Odoo ERP solutions aren’t just tools—they are enablers of digital transformation, helping manufacturers tackle complexity, enhance decision-making, and build resilient operations. With Odoo manufacturing ERP, companies gain access to the top Odoo modules to streamline production and inventory, ultimately delivering measurable gains in efficiency and productivity.

Odoo Manufacturing (MRP) Module: The Backbone of Smarter Production

Among the most powerful Odoo ERP modules available for factories, the Odoo Manufacturing (MRP) module is a cornerstone for streamlining and automating production workflows. This module is purpose-built for complex, multi-step manufacturing processes, offering advanced tools such as work centers, routings, bill of materials (BoM), and production planning. With Odoo for manufacturing, companies can efficiently manage every phase of the manufacturing lifecycle—from raw material consumption to finished goods delivery—within a unified digital environment.

One of the standout features of the Odoo manufacturing ERP module is its real-time scheduling and automation capabilities. Manufacturers can create multi-level BoMs, define custom routing paths, and allocate tasks to specific work centers with live visibility into each production stage. The system supports work order management, barcode scanning, lot and serial number tracking, and even on-the-fly production modifications—all critical features for modern manufacturing management with Odoo. These features make it one of the best Odoo modules for manufacturers seeking agility and operational excellence.

To share a real-world example: A mid-sized automotive component manufacturer and client was struggling with bottlenecks and production delays, deployed the Odoo MRP module. By configuring BoMs and routing workflows across multiple work centers, and using the visual production calendar, our client improved throughput by 22% within six months. This case underscores how Odoo helps manufacturers manage operations more efficiently and highlights the top Odoo modules to streamline production and inventory. With Odoo ERP solutions tailored to factory needs, manufacturers can eliminate inefficiencies, embrace predictive planning, and scale smarter—unlocking true value from their ERP for manufacturing business.

Odoo Inventory Module: Precision Stock Control for Scalable Manufacturing

An integral part of the Odoo manufacturing ERP ecosystem, the Odoo Inventory module delivers robust, real-time inventory control that is essential for modern manufacturing operations. This module features double-entry inventory management, ensuring that every stock movement—from receiving raw materials to delivering finished goods—is automatically recorded across the system. With built-in traceability, batch and serial number tracking, and multi-warehouse management, manufacturers gain unparalleled visibility into inventory flows and can meet stringent quality and compliance standards.

A key strength of the Odoo Inventory module is its integration with other Odoo ERP modules, especially MRP and Sales. When synchronized with the Odoo Manufacturing (MRP) module, it ensures raw material availability is aligned with production schedules, preventing costly delays. When linked to the Sales module, manufacturers can fulfill customer orders with confidence, as real-time stock levels inform both planning and promise dates. This makes it one of the best Odoo modules for manufacturers seeking accuracy and coordination across departments.

The benefits are tangible: users of Odoo for manufacturing experience significant reductions in stockouts and excess inventory, leading to lower carrying costs and higher customer satisfaction. In one case, a consumer electronics manufacturer implemented the Odoo Inventory and MRP modules together, resulting in a 30% improvement in order fulfillment accuracy and a 20% reduction in warehouse turnaround times. These outcomes exemplify how Odoo ERP modules improve factory efficiency, making the inventory module a must-have Odoo ERP module for manufacturing companies. Whether managing a single site or a global supply chain, this tool is among the most essential ERP modules for factories aiming to scale with confidence and precision.

Odoo Quality Management Module: Embedding Compliance and Excellence into Manufacturing

The Odoo Quality Management module, empowers factories to embed quality control directly into their production processes. By defining strategic quality checkpoints across operations—whether during incoming raw material inspection, in-process validation, or post-production testing—manufacturers can systematically catch issues early and uphold high standards.

This module supports a range of essential quality assurance functions including quality alerts, control points, and non-conformance tracking. Alerts can be triggered automatically at any stage, notifying relevant teams about potential deviations. Control points allow users to schedule quality checks on specific products, operations, or work centers, while non-conformance reports help track recurring defects and enforce corrective actions. These features transform quality control from a reactive process to a proactive system, integrated deeply with the broader Odoo ERP modules like Inventory, MRP, and PLM.

The true strength of the Odoo Quality module lies in its ability to reduce rework, prevent defective shipments, and ensure industry-specific compliance—from ISO standards to sector-specific certifications. For a food processing company, implementing Odoo Manufacturing ERP with integrated quality control checkpoints led to a 40% drop in product recalls within six months, proving how Odoo apps for production directly contribute to factory performance. As one of the best Odoo modules for manufacturers, it’s not only essential for maintaining standards but also for enhancing trust, brand equity, and bottom-line efficiency. For any factory looking to streamline operations and improve audit readiness, the Quality module is one of the most must-have Odoo ERP modules for manufacturing companies today.

Odoo Maintenance Module: Maximizing Uptime and Machine Efficiency in Manufacturing

In a modern manufacturing setup, even a brief unplanned machine failure can cascade into production delays, unmet delivery schedules, and increased operational costs. The Odoo Maintenance module is designed to mitigate such risks by enabling preventive and corrective maintenance strategies. As part of Odoo Manufacturing ERP, this module helps manufacturers shift from reactive repair models to proactive maintenance planning—essential for ensuring the reliability of critical equipment on the factory floor.

At its core, the Odoo Maintenance module integrates with MRP and equipment logs, allowing maintenance tasks to be automatically triggered based on usage cycles, performance metrics, or machine-specific thresholds. For instance, a CNC machine can be scheduled for preventive maintenance after completing a set number of production runs. The module also records historical maintenance data—repairs, technician notes, downtime periods—providing a holistic view of each asset’s lifecycle. This deep integration with other Odoo ERP solutions, such as Inventory (for spare part availability) and Manufacturing (to reschedule jobs), and enables teams to manage maintenance without interrupting production flow.

For ERP for manufacturing businesses, the benefits are tangible: reduced unplanned downtime, lower maintenance costs, and extended equipment lifespan. One automotive components manufacturer using Odoo apps for production reported a 30% improvement in mean time between failures (MTBF) and a drop in emergency repair incidents within a year of implementing Odoo Maintenance. As one of the best Odoo modules for manufacturers, it’s a vital tool in any digital transformation roadmap. For companies aiming to enhance asset reliability, minimize costly delays, and achieve factory efficiency, the Maintenance module stands out as a key ERP tool in Odoo for manufacturing success.

Odoo PLM Module: Driving Product Innovation and Operational Excellence

In industries where products are complex, customizable, or frequently updated—such as automotive, electronics, or industrial machinery—the ability to manage engineering changes efficiently is crucial. The Odoo PLM (Product Lifecycle Management) module, part of the broader Odoo ERP Solutions, provides manufacturers with a robust system for controlling product versions, streamlining change approvals, and fostering cross-functional collaboration. As one of the essential ERP modules for factories, Odoo PLM enhances product quality and speed-to-market by integrating engineering workflows directly into production processes.

This Odoo ERP Module allows users to define and track Engineering Change Orders (ECOs), apply version control to Bills of Materials (BoMs), and manage multi-level approvals—all within the same environment as the Odoo Manufacturing ERP. Engineering teams can collaborate in real-time, attach CAD files or technical documentation, and sync directly with Quality and Inventory modules to assess the downstream impact of any design changes. This kind of integration is critical for companies managing high product variability or operating in regulated environments, where traceability and compliance are non-negotiable.

The PLM module’s synchronization with BoM and Quality Control ensures that approved changes automatically cascade to the shop floor, reducing the risk of outdated instructions or unauthorized modifications. For ERP for Manufacturing Businesses, this translates to fewer production errors, lower rework rates, and tighter control over product development cycles. A manufacturer of customizable industrial pumps, for instance, used Odoo PLM to shorten its average change implementation time by 40%—demonstrating real, measurable benefits. As a result, Odoo PLM stands out as one of the best Odoo modules for manufacturers aiming to link engineering with execution and boost overall factory efficiency. It’s a true enabler for businesses looking to gain a competitive edge through innovation and operational alignment.

Other Odoo ERP Modules to Enhance Manufacturing Operations

Beyond the core production-focused modules, several additional Odoo ERP Modules contribute to streamlining and automating end-to-end processes in a manufacturing business. These supporting modules—Odoo Purchase, Odoo Sales, and Odoo Studio—complement the Odoo Manufacturing ERP ecosystem by enabling smart procurement, aligning production with market demand, and allowing factory-specific app customization. Together, they complete a comprehensive Odoo ERP solution that meets the evolving needs of modern manufacturers.

The Odoo Purchase module is essential for managing vendors, tracking procurement activities, and automating replenishment workflows. Manufacturers can configure rules for minimum stock levels, preferred suppliers, and lead times, enabling automatic reordering based on real-time inventory data. This tight integration with the Odoo Inventory and MRP modules ensures production never stalls due to raw material shortages. For companies seeking top Odoo modules to streamline production and inventory, Purchase stands out as a vital component in reducing procurement delays and managing supply chain risks.

On the demand side, the Odoo Sales module plays a crucial role in aligning manufacturing with sales forecasts. By feeding real-time order data directly into the Odoo for Manufacturing workflows, manufacturers can adjust production schedules dynamically and fulfill orders efficiently. This capability empowers manufacturers to be responsive to market changes and customer expectations. Odoo Studio offers a no-code/low-code environment to build custom ERP solutions, allowing businesses to design applications tailored to unique shop floor processes or reporting requirements. For instance, a factory might use Odoo Studio to create a mobile app for machine operators to log production data or initiate quality checks—extending the power of Odoo ERP modules deep into operational workflows.

Together, these tools represent some of the best Odoo modules for manufacturers seeking scalable, configurable, and future-ready ERP for manufacturing businesses. They not only improve visibility and control across departments but also help unlock factory-specific innovations—demonstrating how Odoo helps manufacturers manage operations with unmatched flexibility and precision.

Common Odoo-related Questions that Manufacturers Have

What is Odoo ERP, and how does it benefit manufacturing businesses?

Odoo ERP is an all-in-one business management platform designed to integrate and streamline critical business operations across departments. For manufacturers, this means consolidating production, inventory, procurement, sales, accounting, and more into a unified system. As a leading Odoo ERP solution, it offers flexibility and scalability, making it ideal for small factories and large industrial operations. The platform eliminates data silos, ensures real-time visibility, and simplifies workflow automation.

Implementing Odoo for Manufacturing helps businesses reduce operational inefficiencies by automating routine processes and improving coordination between departments. For instance, the connection between Odoo inventory and MRP modules ensures that raw materials are always available for production, thereby avoiding costly downtimes. This level of integration is essential for businesses looking to maintain agility in a competitive manufacturing landscape. With Odoo ERP modules, manufacturers can track production schedules, manage work orders, monitor equipment, and enforce quality controls — all from a single dashboard.

Odoo Manufacturing ERP delivers real-time analytics and KPI tracking, empowering managers with the insights needed for continuous improvement. Whether it’s optimizing labor allocation or forecasting material requirements, the ERP’s data-driven tools make decision-making strategic. Odoo helps manufacturers manage operations with greater accuracy and speed, resulting in increased output, reduced waste, and improved profitability. It’s no surprise that Odoo ERP solutions are increasingly being adopted by forward-thinking manufacturing businesses worldwide.

2. Which Odoo modules are most essential for manufacturing companies?

When evaluating the best Odoo modules for manufacturers, it’s important to consider the full scope of factory operations. At the core is the Manufacturing (MRP) module, which allows companies to define Bills of Materials (BOMs), manage work centers, plan production, and automate the creation of work orders. This module is essential for managing end-to-end production processes, from planning to execution. When paired with the Inventory module, businesses benefit from accurate stock level monitoring, lot and serial number tracking, and automated stock movements — forming the backbone of manufacturing management with Odoo.

The Purchase module is another critical piece, as it integrates with inventory and production to ensure timely procurement of raw materials. The Sales module links customer orders directly to production plans, enabling real-time manufacturing alignment with market demand. For businesses seeking to ensure product consistency and reduce defects, the Quality module enables the implementation of quality control points at various stages of the manufacturing process. The Maintenance module supports preventive and corrective maintenance schedules, helping minimize machine downtime — a vital requirement for efficient ERP for manufacturing business operations.

The PLM (Product Lifecycle Management) module allows manufacturers to manage engineering changes, collaborate on product development, and maintain version control of products. This module is particularly beneficial for companies with complex production cycles or regulated industries. These must-have Odoo ERP modules for manufacturing companies work together to form a comprehensive solution that streamlines production, boosts efficiency, and ensures end-to-end process control. Collectively, they represent the top Odoo modules to streamline production and inventory, helping manufacturers achieve operational excellence with fewer resources.

3. Can Odoo handle complex manufacturing processes like multi-level BOMs or work orders?

Yes, Odoo is equipped to manage complex manufacturing workflows, including multi-level Bills of Materials (BOMs), routings, and automated work order generation. The Odoo Manufacturing ERP module allows businesses to structure their production processes with precision, supporting discrete and process manufacturing. Whether you’re assembling multi-component products or managing intricate production dependencies, Odoo’s MRP capabilities make it one of the best Odoo modules for manufacturers seeking flexibility and depth.

Multi-level BOMs are essential for manufacturers producing finished goods that consist of sub-assemblies or semi-finished parts. With Odoo’s Manufacturing module, each level of the BOM can be managed independently and linked through routing and operation planning. This feature is crucial for manufacturing management with Odoo, as it helps production teams visualize the full production tree and sequence tasks accordingly. Combined with smart scheduling and resource allocation tools, these capabilities enhance factory efficiency and help reduce production delays and material wastage.

The work order management functionality in Odoo automates task assignments based on predefined routings and production calendars. This ensures that operators, machines, and materials are synchronized. Odoo ERP modules not only simplify complex manufacturing workflows but also improve traceability and compliance. These features demonstrate how Odoo helps manufacturers manage operations at a granular level.

4. How does the Inventory module support manufacturing operations?

The Inventory module in Odoo ERP plays a pivotal role in manufacturing by offering real-time visibility into raw material availability, stock levels, and product movements. For companies aiming to streamline operations, Odoo inventory and MRP modules work in tandem to ensure coordination between warehouse and production floors. This integration is vital for Odoo for Manufacturing, where on-time material provisioning directly impacts production timelines and customer fulfillment.

Odoo’s Inventory module supports advanced stock management features such as multiple warehouses, barcode scanning, batch and serial tracking, and automated replenishment rules. These tools are essential for manufacturers dealing with high-volume or multi-location inventory environments. The module’s ability to provide live updates helps production planners anticipate shortages or overstock situations in real time, which is a cornerstone of Odoo ERP solutions aimed at enhancing operational agility.

Beyond tracking and replenishment, the module also links tightly with Odoo apps for production such as the Manufacturing and Purchase modules. This ecosystem ensures that as soon as a manufacturing order is created, the system checks for stock availability and triggers procurement workflows if necessary. Such end-to-end integration underscores the power of essential ERP modules for factories and highlights key ERP tools in Odoo for manufacturing success. Odoo’s inventory capabilities are among the top Odoo modules to streamline production and inventory, making them indispensable for manufacturers focused on efficiency and scalability.

5. Can Odoo help manage equipment maintenance and quality control?

Yes, Odoo provides robust support for managing both equipment maintenance and quality control through its dedicated Maintenance and Quality modules. These Odoo ERP modules are particularly vital for manufacturers that rely on high-value machinery and rigorous production standards. As part of a comprehensive Odoo manufacturing ERP solution, these modules ensure that critical assets remain operational and that product quality meets or exceeds expectations throughout the production cycle.

The Maintenance module enables both preventive and corrective maintenance planning. Manufacturers can schedule periodic inspections, automate maintenance requests, assign technicians, and track equipment performance — all within the Odoo platform. This not only reduces unexpected breakdowns but also extends equipment lifespan, supporting overall factory efficiency. As a key component of manufacturing management with Odoo, the maintenance workflow integrates seamlessly with production schedules to minimize downtime and ensure continuous output.

The Quality module allows businesses to implement quality control points at various stages of production, including raw material intake, in-process checks, and final inspections. You can define quality control plans, record test results, and trigger corrective actions automatically. These features make Odoo one of the best Odoo modules for manufacturers looking to standardize and enforce compliance. Together, these Odoo ERP solutions play a crucial role in ensuring that your ERP for manufacturing business covers every operational aspect — from asset care to product reliability.

6. Is it possible to customize Odoo modules to fit unique manufacturing needs?

Absolutely. One of the standout advantages of Odoo ERP solutions is their modular, open-source architecture that allows extensive customization. Whether you’re a small workshop or a large-scale factory, you can tailor Odoo’s capabilities to your unique processes, industry regulations, or production methods. From configuring custom workflows to building entirely new Odoo apps for production, the platform adapts easily to the specific demands of your ERP for manufacturing business.

Customizations can include specialized dashboards, unique reporting structures, additional data fields, user role permissions, and automated triggers across your Odoo ERP modules. For example, if your production process includes a non-standard QA loop, you can tweak the Quality module accordingly. Or if you manage proprietary equipment with complex maintenance cycles, the Maintenance module can be extended to include custom scheduling logic. This ability to align digital tools with operational needs is essential for manufacturing management with Odoo, where no two production lines are exactly alike.

As your business grows, Odoo’s customizability ensures that your ERP evolves alongside it. You can start with the essential ERP modules for factories and gradually build out more advanced features like PLM or IoT integration. This modular and scalable approach is what makes Odoo one of the must-have Odoo ERP modules for manufacturing companies. These flexible key ERP tools in Odoo for manufacturing success empower manufacturers to improve efficiency, reduce costs, and maintain full control over their production environment.

Schedule a conversation with us now!

Related Articles

-

Post

AI Agents in Odoo ERP: Transforming eCommerce Order Fulfillment for US Retailers

AI Agents in Odoo ERP: Transforming eCommerce Order Fulfillment for US Retailers January 7, 2026 Posted by: Tony Categories: AI, Blog No Comments The US Retailer’s Dilemma in the Age of Instant Gratification The friction created by disconnected systems and manual processes contradicts the gratification consumers demand. This operational lag not only erodes margins but -

Post

How Odoo 19 AI Automation Cuts Retail Stockouts by 50%

How Odoo 19 AI Automation Cuts Retail Stockouts by 50% December 30, 2025 Posted by: Tony Categories: AI Workflow automation, Blog No Comments The Billion-Dollar Problem on Your Shelf When a customer encounters an empty shelf or a “temporarily unavailable” notice online, the result is a lost sale. The long-term cost is greater. It is -

Post

Why Packaging Companies Are Turning to Odoo For Higher Growth and Improved Efficiency

Why Packaging Companies Are Turning to Odoo For Higher Growth and Improved Efficiency December 24, 2025 Posted by: Tony Categories: Blog, Odoo No Comments The packaging industry in the USA and Europe stands at a critical crossroads. The sector faces mounting challenges, including volatile raw material and energy prices and increasingly stringent environmental regulations. In

How can we help you?

Get in touch with a solutions consultant that can share best practices and help solve specific challenges.