The Hidden Costs of Delaying Your Manufacturing ERP Migration to Odoo

- April 22, 2025

- Posted by: Tony

- Categories: Blog, ERP Migration

Manufacturers operating without a modern ERP system often face hidden costs that escalate over time. Delaying your Odoo ERP migration for manufacturing can lead to inefficiencies in inventory management, production planning, and supply chain coordination, resulting in increased operational expenses and lost revenue. Manual processes and disconnected systems create data silos, making real-time decision-making nearly impossible. Without an integrated ERP, manufacturers struggle with inaccurate demand forecasting, production bottlenecks, and excessive downtime, all of which impact profitability. Migrating to Odoo ERP at the right time ensures that these issues are resolved before they start draining resources.

Beyond operational inefficiencies, delaying ERP migration also raises concerns about Odoo ERP data integrity and security. Legacy systems often lack robust security measures, leaving sensitive business data vulnerable to breaches. Additionally, outdated systems may not support Odoo ERP platform compatibility, causing integration challenges with third-party applications and future software upgrades. A proactive migration enables manufacturers to leverage Odoo ERP performance management, ensuring streamlined workflows, automated reporting, and optimized resource utilization. Investing in Odoo ERP migration for manufacturing today prevents escalating costs and positions businesses for long-term growth and scalability.

The Growing Financial Burden of Legacy Manufacturing ERP

Manufacturing companies relying on legacy ERP systems face increasing financial strain that extends beyond operational expenses. Businesses using outdated on-premise ERP solutions often allocate up to 60% of their IT budget to maintenance, while those that transition to modern Odoo ERP migration for manufacturing significantly reduce these costs. A delay in upgrading not only increases IT expenditures but also impacts scalability, efficiency, and long-term profitability.

Escalating Maintenance and Support Costs

Legacy ERP systems demand constant upkeep, requiring specialized IT professionals to monitor, troubleshoot, and support aging infrastructure. This leads to rising labor costs and prolonged downtime. Additionally, modifying outdated systems often requires custom code, introducing bugs that necessitate frequent fixes. With Odoo ERP platform compatibility, manufacturers can eliminate the need for excessive manual intervention while ensuring seamless integrations with modern applications.

Hidden Infrastructure Expenses

Maintaining legacy ERP infrastructure comes with hidden costs, including:

- Hardware maintenance and replacement

- Specialized licensing fees

- Integration costs with modern technologies

- Security updates and patches

Failure to migrate to a modern ERP like Odoo increases technical debt, making it progressively more expensive to keep outdated systems functional. With Odoo ERP data integrity and security, manufacturers can protect sensitive business data and minimize cybersecurity risks associated with legacy platforms.

Lost Revenue Opportunities from Outdated Systems

Legacy ERP systems hinder revenue growth by creating inefficiencies in supply chain management, production planning, and customer service. System vulnerabilities expose manufacturers to risks, including data breaches and operational disruptions. Over time, outdated software becomes increasingly rigid, slowing down response times and preventing manufacturers from capitalizing on new market opportunities. Implementing Odoo ERP performance management enhances system responsiveness, streamlines workflows, and enables manufacturers to scale efficiently without costly delays.

Operational Inefficiencies Are Costing You Money

Outdated manufacturing systems introduce inefficiencies that disrupt the entire production ecosystem. Manufacturers relying on manual processes experience a 23% increase in operational costs and a 22% rise in administrative expenses. Delaying an Odoo ERP migration for manufacturing prolongs these inefficiencies, driving up costs and limiting business agility.

Manual Process Overhead and Labor Costs

Legacy systems force manufacturers to rely on labor-intensive workflows that drain resources. Employees spend excessive hours gathering operational data, leading to productivity losses and higher labor costs. With Odoo ERP performance management, companies can automate routine processes, reduce manual workloads, and improve overall efficiency.

Inventory Management Inefficiencies

Poor inventory tracking creates major financial risks. Organizations without modern ERP systems experience:

- Rush shipping costs due to negative inventory

- Cash flow issues from excess stock

- Customer dissatisfaction when inventory accuracy drops below 90%

Without Odoo ERP data integrity and security, manufacturers struggle with real-time inventory visibility, forcing them to maintain surplus stock as a safeguard. Odoo ERP platform compatibility enables seamless inventory tracking, reducing waste and optimizing stock levels.

Production Planning Bottlenecks

Ineffective production planning disrupts multiple aspects of manufacturing, leading to machine utilization dropping 20-30% below optimal levels. These issues arise from:

- Lack of real-time scheduling validation

- Poor tracking of resource conflicts

- Missing immediate production data

Delaying an Odoo ERP migration for manufacturing results in twice the production delays compared to modern solutions. With Odoo ERP performance management, manufacturers gain 99% inventory accuracy and cut inventory costs in half, ensuring smooth operations and optimized production planning.

The Real Cost of Delayed Odoo ERP Migration for Manufacturing

Postponing an Odoo ERP migration for manufacturing has significant financial consequences that go beyond direct operational expenses. Studies show that companies delaying ERP upgrades suffer lower ROI, rising inefficiencies, and missed growth opportunities.

Employee Productivity Loss

Legacy ERP systems reduce workforce efficiency, increasing training costs by 35% annually and causing 30% higher employee turnover due to system frustration. New employees take twice as long to become proficient with outdated systems, while 71% of workers lose over two hours per week struggling to access company information. Upgrading to Odoo ERP platform compatibility enhances user experience, accelerates onboarding, and improves overall workforce productivity.

Customer Satisfaction Impact

Outdated ERP systems weaken customer relationships by slowing response times and reducing service quality. Companies that delay their Odoo ERP migration for manufacturing experience declining customer satisfaction scores. The impact on order fulfillment is particularly severe—businesses postponing ERP upgrades see reduced on-time delivery rates, while those adopting Odoo ERP performance management achieve 98% delivery accuracy, leading to higher customer retention.

Missed Process Optimization Opportunities

Delaying ERP migration results in major financial losses over time. Manufacturers postponing Odoo ERP data integrity and security upgrades miss out on 35% potential inventory cost reductions and fail to optimize supply chain operations. Meanwhile, competitors leveraging Industry 4.0 technologies through Odoo ERP platform compatibility significantly improve efficiency. Companies resisting migration face 40% higher operational costs than those with modern ERP systems, putting them at a long-term competitive disadvantage.

Data Security Risks and Compliance Costs

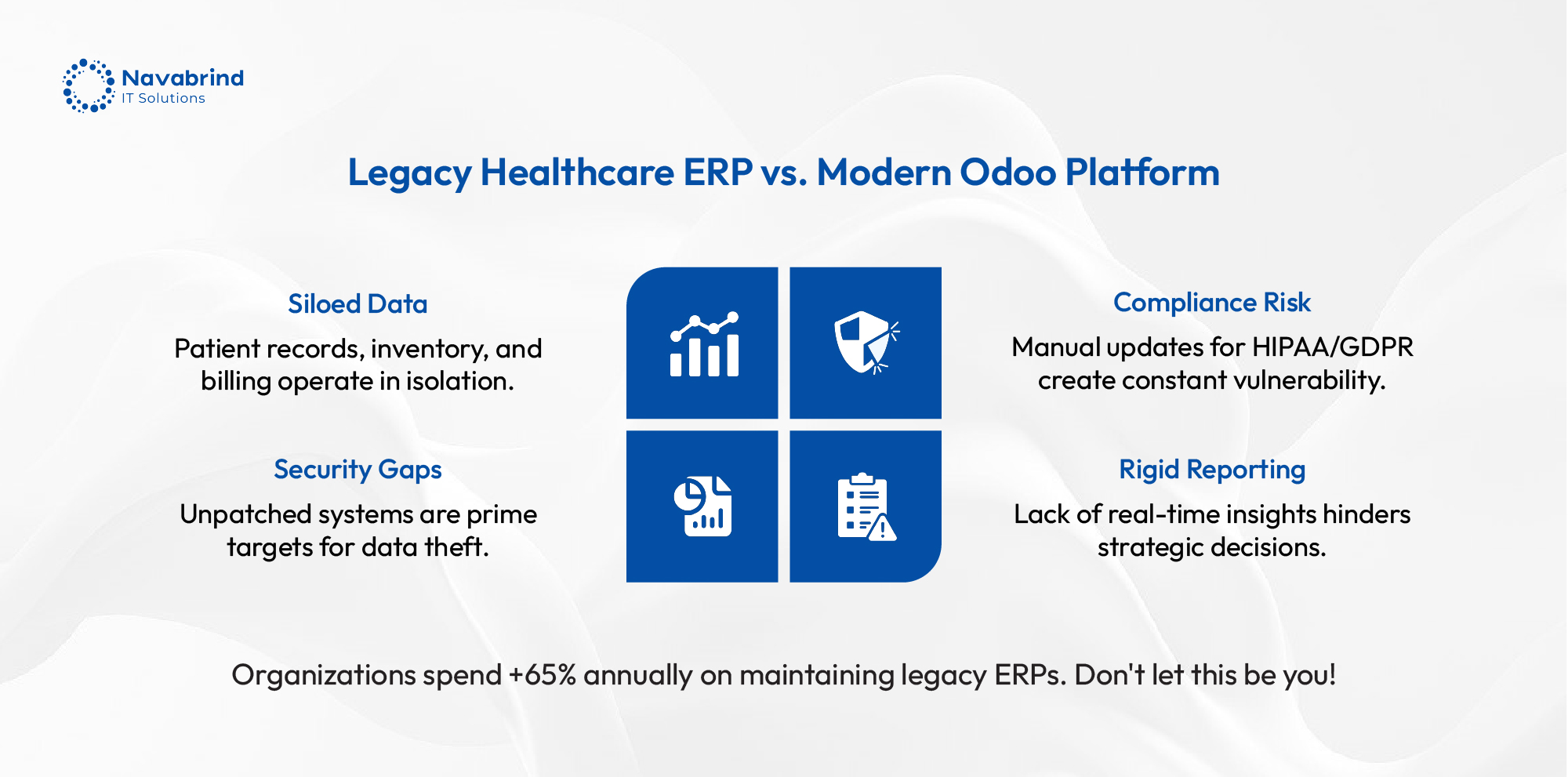

Security flaws in legacy manufacturing systems are becoming a major threat to business operations. Research shows manufacturing makes up over 65% of industrial ransomware attacks. This creates an urgent need for Odoo ERP data integration and security for manufacturing.

Outdated Security Measures

Legacy ERP systems lack many security features because developers created them before modern cyber threats emerged. Manufacturing companies with old systems face challenges such as:

- No current security patches and updates

- Poor compatibility with modern security protocols

- Weak monitoring and logging capabilities

- Not enough protection against new threats

These problems get worse as systems get older and eventually, manufacturing units can’t keep up with security protocols.

Regulatory Non-Compliance Penalties

Companies pay heavy fines when their legacy systems don’t meet regulatory standards. Manufacturers handling sensitive data face bigger risks from outdated ERP systems that can’t maintain compliance. Data breaches from outdated ERP systems come with massive costs. Odoo ERP for manufacturing offers encryption and improved security features that prevent these expensive breaches.

Impact on Business Growth and Scalability

Outdated manufacturing ERP systems limit business expansion, reduce market agility, and hinder digital transformation. Companies relying on legacy systems grow 35% slower than those adopting modern solutions like Odoo ERP migration for manufacturing, leading to competitive disadvantages.

Limited Market Expansion Capabilities

Data reveals that 75% of businesses experience system slowdowns when scaling operations. These roadblocks appear as:

- Inability to handle increasing transaction volumes

- Insufficient support for new business units

- Barriers to entering new markets

- System crashes during peak periods

As companies grow, these challenges intensify, reducing operational efficiency and profitability. Businesses delaying their Odoo ERP migration for manufacturing see lower ROI, while competitors benefit from improved Odoo ERP performance management and scalability.

Integration Challenges with Modern Tools

Legacy systems struggle with Odoo ERP platform compatibility, making it difficult to connect with modern business applications. Research shows that ERP implementations often fail due to integration issues. Manufacturers using outdated systems face challenges when integrating:

- Cloud-based applications

- Mobile workforce solutions

- Advanced analytics and AI platforms

- Digital commerce channels

Maintaining these outdated connections drains IT budgets, while businesses adopting Odoo ERP data integrity and security benefit from seamless, real-time data synchronization.

Innovation Constraints

Old ERP systems divert IT budgets toward maintenance rather than innovation, restricting companies from:

- Adopting emerging technologies

- Exploring new business models

- Responding quickly to market changes

- Advancing digital transformation initiatives

Odoo ERP migration for manufacturing offers an expandable, future-ready platform that supports innovation and agility. Companies using modern ERP solutions reduce inventory costs by 35%, free up capital, and significantly lower IT maintenance expenses. While legacy system users spend 3% of revenue on outdated ERP upkeep, businesses with Odoo ERP performance management cut this cost to 0.1%, freeing resources for growth and technological advancement.

Are you ready to engage in Odoo ERP performance management and partner with Navabrind IT Solutions for your Odoo ERP migration?

Partnering with Navabrind IT Solutions for Odoo ERP migration for manufacturing ensures a smooth transition with minimal disruption. As an Odoo Gold Partner, we bring deep expertise in manufacturing ERP implementation, optimizing processes like inventory management, production planning, procurement, and supply chain automation. Our team customizes Odoo to fit your business needs, integrating real-time tracking, automated workflows, and advanced reporting for better decision-making and cost efficiency. With proven experience across industries, we ensure a smooth migration, maximizing ROI and operational efficiency for manufacturers looking to scale and modernize.

Frequently Asked Questions

1. What are some hidden costs associated with delaying ERP migration for manufacturers?

Delaying the migration to a modern ERP system like Odoo can lead to hidden costs that significantly impact a manufacturer’s bottom line and operational efficiency.

- Escalating Maintenance Costs: Legacy systems often require extensive maintenance to remain operational. Manufacturers may spend up to 80% of their IT budget on maintaining outdated systems, leaving minimal resources for innovation or scaling operations.

- Increased Security Vulnerabilities: Outdated ERP systems lack modern security protocols, exposing manufacturers to cyber threats. Data breaches, ransomware attacks, and system downtimes can result in both direct financial losses and reputational damage.

- Lost Revenue Opportunities: Legacy systems often lack the capabilities to support new revenue streams, such as multi-channel sales or data-driven manufacturing initiatives. This can result in missed opportunities to capitalize on emerging markets.

- Missed Process Optimization: Without real-time insights or automated workflows, manufacturers experience higher operational costs and reduced productivity. Delaying Odoo ERP migration for manufacturing means postponing access to features like dynamic inventory management and real-time production tracking.

2. How does an outdated ERP system impact customer satisfaction in manufacturing?

Outdated ERP systems directly affect customer satisfaction due to inefficiencies in production, inventory management, and order processing.

- Slower Response Times: Legacy systems often fail to provide real-time data, leading to delayed responses to customer inquiries or service issues. Manufacturers using outdated systems report a 12% decline in customer satisfaction scores.

- Reduced On-Time Delivery Rates: Legacy systems lack the tools for precise inventory tracking and production planning. This can lead to lower on-time delivery rates—often falling below 88%. Modern ERP solutions like Odoo ERP for manufacturing can improve delivery performance to 98% by providing real-time data and automated order management.

- Limited Customization and Scalability: Legacy systems are less adaptable to changing customer needs, resulting in a diminished ability to meet specific client requirements.

- Odoo ERP Data Integrity and Security: By migrating to Odoo, manufacturers can ensure accurate and secure data flow across departments, enabling faster, more reliable service.

Investing in a modern ERP like Odoo enhances operational efficiency and provides customers with the high-quality experience they expect.

3. What are the security risks of using legacy manufacturing ERP systems?

Legacy ERP systems pose significant security risks, in the increasingly digitized landscape of manufacturing.

- Inadequate Protection Against Emerging Threats: Older systems are often incompatible with modern security protocols and lack the ability to address new cyber threats. As a result, manufacturing accounts for over 65% of industrial ransomware attacks.

- Limited Monitoring Capabilities: Legacy systems lack advanced monitoring tools, making it harder to detect suspicious activities in real-time.

- Compatibility Challenges: Outdated ERPs are often unable to integrate with modern cybersecurity tools, leaving gaps in protection. Transitioning to Odoo ERP platform compatibility ensures seamless integration with up-to-date security technologies.

- Data Integrity Risks: Without robust encryption and compliance features, legacy systems expose sensitive manufacturing data to theft. Odoo offers data integrity and security features like role-based access control and end-to-end encryption to mitigate such risks.

Odoo ERP migration for manufacturing ensures uninterrupted operations and protects sensitive manufacturing data.

4. How does delaying ERP migration affect a manufacturer's ability to expand and innovate?

Delaying ERP migration hinders growth and innovation by limiting operational flexibility and scalability.

- Slower Market Expansion Rates: Companies relying on legacy systems experience 35% slower market expansion compared to those using modern ERP solutions. Outdated systems struggle to handle increased workloads or adapt to new market demands.

- Integration Challenges: Legacy ERPs are often incompatible with modern tools, such as IoT devices or advanced analytics platforms, restricting manufacturers from leveraging data-driven innovations.

- Higher Maintenance Costs: Businesses using legacy systems allocate 50% to 90% of their IT budget to maintenance, leaving little room for innovation or strategic initiatives.

- Limited Performance Optimization: Delaying migration to solutions like Odoo ERP performance management prevents access to tools for optimizing production processes, such as real-time KPI tracking and automated workflows.

By implementing Odoo ERP, manufacturers can achieve greater operational agility, enabling them to innovate and expand more effectively.

5. What are the potential c. What are the potential cost savings of migrating to a modern ERP system like Odoo for manufacturing?

Migrating to Odoo ERP offers substantial cost savings while enhancing operational efficiency.

- Inventory Accuracy: Odoo’s advanced inventory features, such as automated replenishment and lot tracking, can achieve 99% accuracy, reducing inventory-related costs.

- Operational Cost Reduction: Companies using Odoo report up to a 35% reduction in operational costs through features like automated production scheduling and real-time data analysis.

- Reduced Inventory Costs: By optimizing stock levels and minimizing excess inventory, Odoo helps manufacturers cut on-hand inventory costs by as much as 50%.

- Security Risk Reduction: Odoo’s data integrity and security features, including encryption and compliance tools, lower the financial risks associated with data breaches and cyberattacks.

- Resource Allocation for Innovation: By streamlining operations and reducing maintenance costs, Odoo frees up resources that can be redirected toward R&D, product development, and market expansion.

Investing in Odoo ERP migration for manufacturing delivers significant ROI, enabling manufacturers to achieve long-term growth.

Schedule a conversation with us now!

Related Articles

-

Post

From Legacy Healthcare ERP to Odoo ERP: Why You Need Expert Odoo Migration Help

From Legacy Healthcare ERP to Odoo ERP: Why You Need Expert Odoo Migration Help February 11, 2026 Posted by: Tony Category: Uncategorized No Comments Why Healthcare Organizations Need Odoo ERP Migration Legacy healthcare ERP systems create barriers to efficiency. They are expensive to maintain, and struggle to integrate tools. This disconnect impacts patient care coordination, -

Post

From LLMs to Agentic AI: A Practical Guide to What They Mean and How to Choose

From LLMs to Agentic AI: A Practical Guide to What They Mean and How to Choose February 4, 2026 Posted by: Tony Categories: Artificial Intelligence, Blog No Comments As definitions, use cases, expectations, and investments around Large Language Models (LLMs), Retrieval-Augmented Generation (RAG), AI agents, and agentic AI continue to expand, many individuals and organizations -

Post

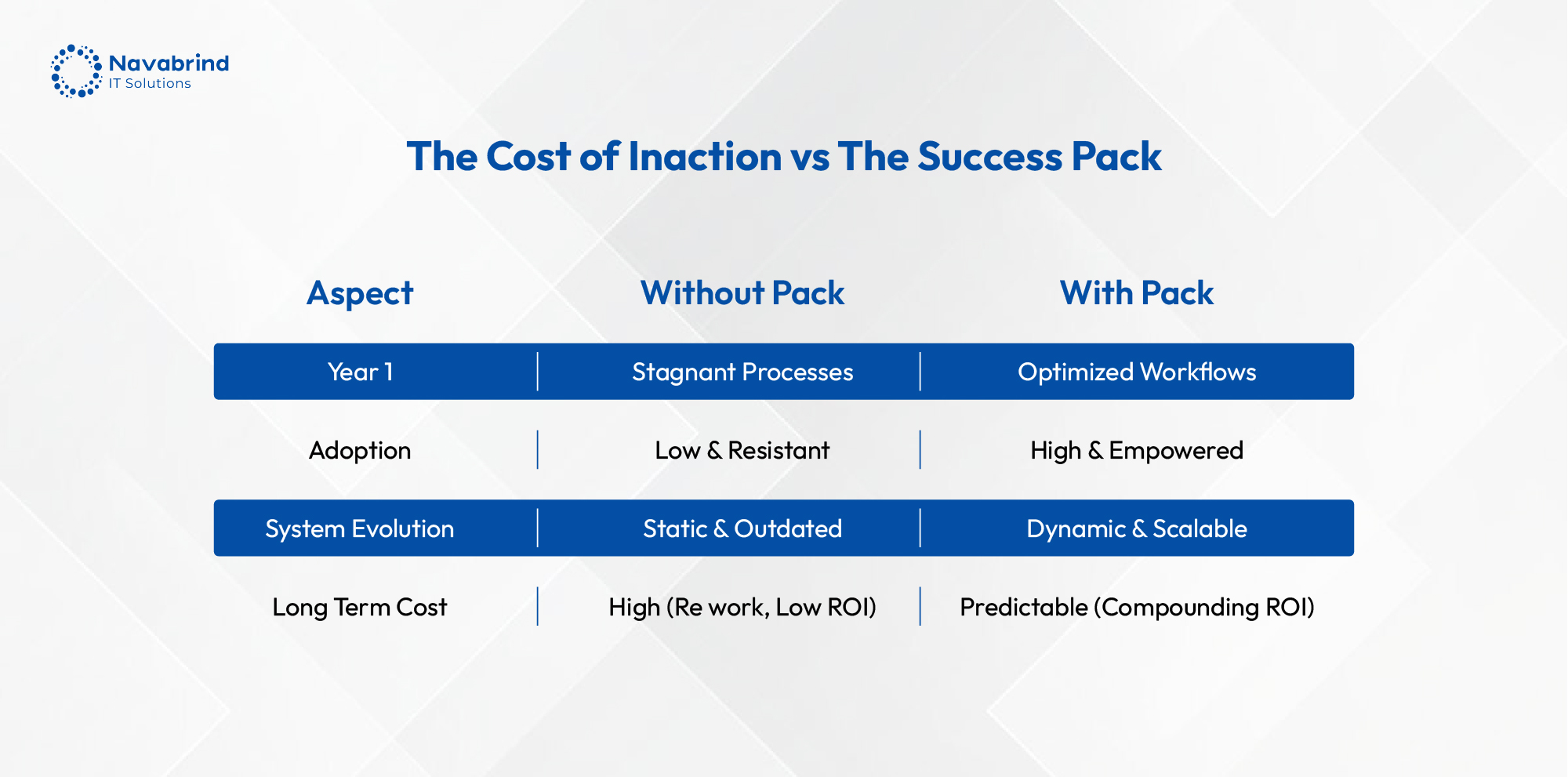

Beyond Go-Live: How Your Odoo Success Pack Drives Real, Long-Term ROI

Beyond Go-Live: How Your Odoo Success Pack Drives Real, Long-Term ROI February 3, 2026 Posted by: Category: Uncategorized No Comments The Implementation Myth Businesses mistakenly measure ERP success by completing the implementation phase while the actual measure of value is the operational transformation unlocked after go-live. The Odoo Success Pack is the framework engineered to

How can we help you?

Get in touch with a solutions consultant that can share best practices and help solve specific challenges.