Top 5 Manufacturing Pain Points Solved with Odoo ERP

- May 6, 2025

- Posted by: Vasanth Anantharaman

- Categories: Blog, Odoo Manufacturing

Manufacturing operates in a high-pressure environment marked by fluctuating demand, global competition, supply chain disruptions, and rising operational costs. For manufacturers to remain competitive, agility, efficiency, and real-time visibility are non-negotiable. Unfortunately, many companies still struggle with legacy systems or fragmented tools that fail to deliver the insights and control required to thrive in this complex landscape.

This is where Odoo ERP for manufacturing stands out as a powerful, modular, and highly customizable solution. Designed to solve some of the most pressing pain points in the manufacturing industry, Odoo empowers businesses to centralize operations, automate workflows, and gain data-driven insights across departments. Whether you’re dealing with bottlenecks in production planning, poor inventory management, or lack of integration across functions, Odoo ERP solutions provide the tools needed to overcome these hurdles.

In this blog post, we’ll explore the top manufacturing challenges solved with Odoo, and how the ERP’s rich functionality—including the Odoo Manufacturing module—helps optimize core functions like MRP, quality control, and compliance. You’ll learn how ERP for the manufacturing industry is no longer just a back-office tool, but a strategic enabler of performance and growth.

By highlighting key Odoo ERP benefits and real-world use cases, we’ll demonstrate why Odoo is one of the best ERP solutions for solving manufacturing bottlenecks—and how manufacturers can experience real value by customizing their ERP system to fit their needs.

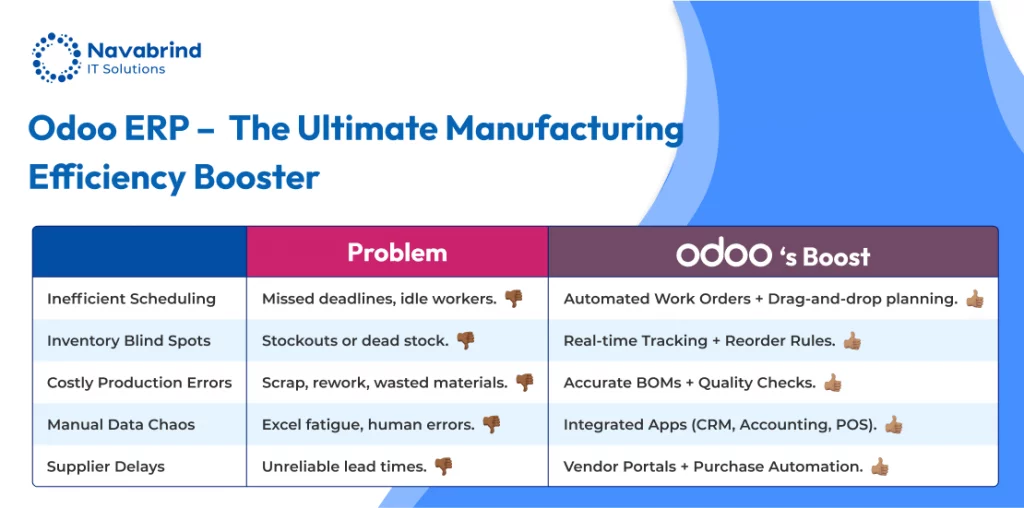

Pain Point #1: Inefficient Production Planning and Scheduling

A critical pain point in the manufacturing industry is inefficient production planning and scheduling. Many manufacturers still rely on manual spreadsheets or disconnected systems that fail to provide a real-time overview of production capacity, raw material availability, and order priorities. This results in missed deadlines, underutilized resources, and production issues that impact profitability.

Odoo ERP for manufacturing addresses these issues with its robust Manufacturing module, designed to streamline planning across every stage of production. With Odoo ERP features for manufacturing, businesses can define and manage Bills of Materials (BoMs), work centers, routings, and manufacturing orders from a single, integrated dashboard. The system’s Master Production Schedule (MPS) tool allows for accurate forecasting based on demand, capacity, and inventory levels, helping manufacturers align resources with actual production needs.

By implementing Odoo ERP solutions, manufacturers gain the ability to schedule operations with precision, reduce machine idle time, and improve on-time delivery rates. The ERP also supports Material Requirements Planning (MRP), enabling real-time coordination between procurement, inventory, and production departments. This helps avoid both stockouts and overproduction.

Streamlining production planning with Odoo ERP not only enhances operational efficiency but also allows decision-makers to respond faster to changing market conditions. For manufacturers looking to scale, automate, and improve visibility, Odoo ERP benefits are both immediate and long-term. It’s no surprise that many leading companies now consider Odoo the best ERP for solving manufacturing bottlenecks.

Pain Point #2: Poor Inventory Visibility and Control

One of the top manufacturing challenges solved with Odoo ERP is the persistent lack of inventory visibility and control. For many manufacturers, fragmented systems lead to inaccurate stock levels, misplaced inventory, and inefficient warehouse operations. These issues disrupt production schedules, cause delays, and inflate operational costs.

Odoo ERP for Manufacturing offers an advanced inventory management module tightly integrated with other business functions such as production, procurement, and sales. This real-time, unified approach enables manufacturers to monitor raw materials and finished goods with complete accuracy. The system’s dynamic inventory tracking supports batch numbers, serial numbers, barcodes, and multi-warehouse operations, giving manufacturers total control over their stock.

By using Odoo Manufacturing Module, businesses gain automated stock replenishment capabilities through defined reordering rules, minimum stock thresholds, and real-time alerts. These features eliminate overstocking and stockouts, which are common pain points in the manufacturing industry. With Odoo ERP features for manufacturing, manufacturers can streamline their supply chain, reduce lead times, and optimize warehouse efficiency.

For enterprises seeking reliable ERP software for production issues, Odoo ERP solutions offer customizable dashboards, smart filters, and detailed reporting. These tools provide deep insights into inventory trends, turnover rates, and storage costs—empowering manufacturers to make data-driven decisions.

How Odoo ERP solves inventory management issues in manufacturing is a testament to its comprehensive design and flexibility. Whether managing raw materials, work-in-progress, or finished products, Odoo provides manufacturers with the control they need to scale efficiently and reduce waste. It’s one of the key reasons why Odoo is considered a leading ERP for manufacturing industry needs today.

Pain Point #3: Lack of Real-Time Data and Insights

In the manufacturing industry, decisions must be made quickly and accurately to maintain efficiency, reduce downtime, and meet production targets. However, many manufacturers struggle with siloed data and outdated reporting tools. This lack of real-time visibility into operations is a critical pain point.

Odoo ERP for manufacturing addresses this challenge by providing a centralized platform that unifies data from production, inventory, sales, procurement, and finance into one cohesive system. The Odoo Manufacturing module is equipped with powerful dashboards and advanced reporting tools that enable stakeholders to monitor KPIs, track production performance, and respond proactively to problems.

With Odoo’s real-time analytics capabilities, manufacturers can identify inefficiencies and predict future outcomes, making it an ideal ERP for manufacturing industry players. The platform’s built-in business intelligence tools allow users to create customized reports and visualizations without needing external software.

Odoo ERP features for manufacturing include real-time alerts, timeline-based production tracking, and live inventory levels. These capabilities help manufacturers maintain control over fast-moving processes and detect issues before they escalate. For businesses searching for ERP software for production issues, Odoo delivers the transparency and control required to thrive in a competitive market.

How Odoo helps manufacturers is not just about capturing data—it’s about transforming that data into insights. With integrated modules and automation, manufacturers no longer need to rely on static reports. Instead, they benefit from continuous, data-driven decision-making across departments.

This is why top manufacturing challenges solved with Odoo ERP often begin with visibility. From machine uptime tracking to order fulfillment status, Odoo ensures every part of the operation is visible in real time.

Pain Point #4: Inflexible Production Scheduling and Resource Allocation

A persistent challenge in the manufacturing industry is the inability to adapt production schedules in real-time. Traditional ERP systems or manual scheduling tools often fail to accommodate sudden changes—whether it’s a supply chain delay, a rush order, or a machine breakdown. This inflexibility results in production hurdles, wasted resources, missed deadlines, and higher operational costs.

Odoo ERP for manufacturing offers a robust solution through its dynamic Odoo Manufacturing module, which enables manufacturers to build, adjust, and optimize production schedules with ease. With intuitive drag-and-drop tools and rule-based planning, manufacturers can allocate resources based on availability, workload, and delivery priorities—transforming how they manage operations.

Another pain point in the manufacturing industry is aligning workforce, machinery, and materials at the right time. Odoo’s integrated ERP software for production issues solves this by synchronizing work orders, labor assignments, and inventory levels in real-time. The system enables quick decision-making and seamless adjustments to accommodate real-world disruptions.

What sets Odoo ERP features for manufacturing apart is the platform’s ability to simulate various production scenarios before execution. This ensures manufacturers can test capacity and identify constraints early—making streamlining production planning with Odoo ERP not just possible but efficient and cost-effective.

Manufacturers dealing with high-mix, low-volume production—such as those in automotive, electronics, or custom machinery—benefit from Odoo’s advanced planning and scheduling (APS) capabilities. These features allow for granular control over every production stage, helping companies reduce lead times and improve customer satisfaction.

How Odoo helps manufacturers is by turning inflexible, reactive planning into agile, responsive scheduling—powered by automation and real-time data. For enterprises seeking the best ERP for solving manufacturing bottlenecks, Odoo proves to be the platform of choice, enabling them to scale production while keeping operations lean and efficient.

This flexibility is one of the top Odoo ERP benefits and a major reason manufacturers choose Odoo ERP for operations. With better resource utilization, accurate production timelines, and built-in forecasting, Odoo empowers manufacturers to stay ahead of market demands and operational challenges.

Pain Point #5: Complex Compliance and Quality Management Requirements

Another pain point in the manufacturing industry is ensuring consistent product quality while meeting evolving regulatory standards. From ISO certifications and environmental regulations to sector-specific requirements like EMEA, CAPA, and PPAP, manufacturers must manage compliance protocols that traditional systems struggle to support.

This is where Odoo ERP for manufacturing provides a strategic advantage. Through its powerful Odoo Manufacturing module, the platform offers built-in tools for quality control, compliance tracking, and process standardization—making it an effective manufacturing ERP solution on the market today.

How Odoo helps manufacturers address these challenges is by enabling automated quality checks at every stage of production. Whether it’s raw material inspection, in-process quality audits, or final product verification, Odoo’s ERP software for production issues ensures that defects are caught early—reducing rework, returns, and reputational risk.

Manufacturers can create customized quality control points, link them to specific operations or product batches, and define acceptance criteria, ensuring full traceability and accountability. This level of customization makes Odoo ERP customization vital for industries with strict compliance and quality management needs, such as automotive, pharmaceuticals, and electronics.

Odoo ERP features for manufacturing include detailed documentation workflows and audit trails, helping companies demonstrate compliance with internal policies and external regulations. This is essential for passing audits, minimizing legal exposure, and securing customer trust.

For businesses dealing with stringent regulatory frameworks, streamlining production planning with Odoo ERP also extends to compliance alignment. Real-time data visibility ensures proactive decision-making and allows for quick adjustments to meet changing compliance standards without disrupting production.

The ability to configure approval flows, track non-conformities, and integrate CAPA procedures makes Odoo the best ERP for solving manufacturing bottlenecks caused by compliance failures and poor quality control.

Real-World Impact: Odoo ERP Benefits in Action

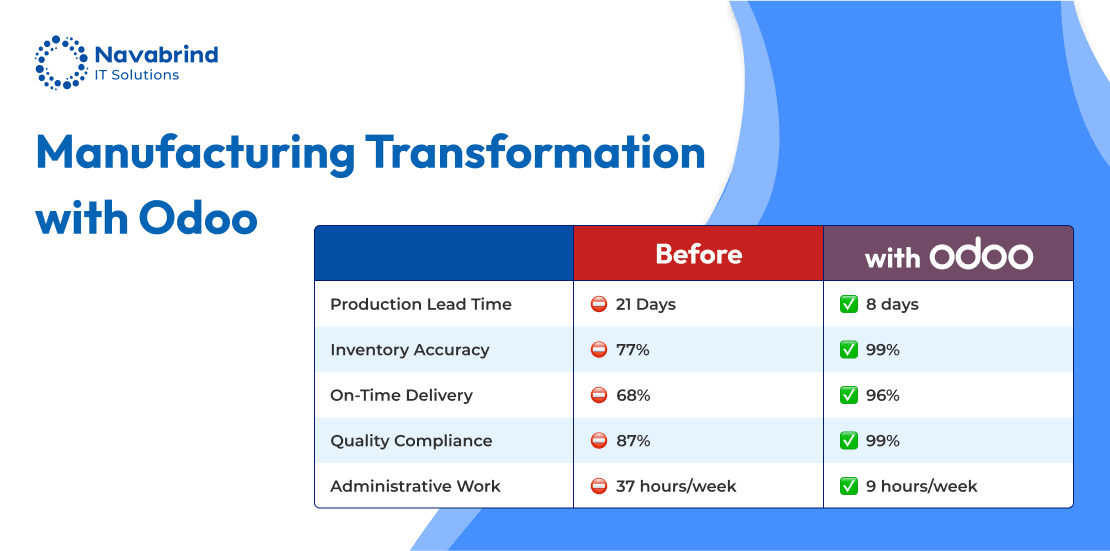

The true value of any ERP system lies in the measurable outcomes it delivers. With Odoo ERP for manufacturing, organizations have witnessed transformative gains across critical operational metrics.

- 72% Reduction in Manual Effort

Manufacturers who replaced outdated systems with the Odoo Manufacturing module report a 72% decrease in manual, repetitive tasks. By automating production planning, inventory tracking, quality control, and workflow approvals, Odoo significantly reduces human errors and labor costs—streamlining operations from shop floor to shipment.

- 80% Boost in Customer Satisfaction (CSAT)

Thanks to real-time visibility across the supply chain, on-time delivery rates have soared. By implementing Odoo ERP features for manufacturing, such as demand forecasting, order fulfillment automation, and after-sales support tracking, businesses have seen their CSAT scores increase by up to 80%—a clear indication of improved customer experience and service reliability.

- 45–75% Increase in Profit Margins

Clients leveraging Odoo ERP customization to address specific pain points in the manufacturing industry—including complex MRP workflows, BOM optimization, and multi-level routing—have recorded profit margin growth of up to 75%. These gains are attributed to smarter resource allocation, lower wastage, optimized procurement, and minimized downtime.

- 95% On-Time Delivery

With powerful ERP software for production issues, manufacturers have tightened delivery cycles and improved scheduling accuracy. Odoo’s real-time dashboards and integrated modules ensure production issues are identified and resolved proactively—enabling an average 95% on-time delivery rate.

- 500+ Custom Workflows Deployed

Through extensive Odoo ERP customization, manufacturers have tailored the platform to meet unique requirements such as PPAP, APQP, EMEA, and CAPA standards. Navabrind IT Solutions alone has implemented 500+ custom workflows, helping businesses achieve seamless regulatory compliance without disrupting production flow.

Why Choose Odoo ERP for Manufacturing

Odoo ERP for manufacturing offers the ideal blend of flexibility, scalability, and cost-effectiveness—making it the preferred ERP for the manufacturing industry across sectors such as automotive, electronics, textiles, chemicals, and more.

Unlike rigid, one-size-fits-all platforms, Odoo stands out for its modular open-source architecture, allowing manufacturers to implement only the features they need and scale as operations evolve. This approach not only accelerates time-to-value but also ensures a higher return on investment (ROI). From production planning and inventory control to quality assurance, equipment maintenance, and financial management, every module in the Odoo Manufacturing module is designed to address core manufacturing challenges.

-

Solving Top Manufacturing Challenges

Whether it’s minimizing unplanned downtime, eliminating stockouts, or meeting strict compliance requirements, Odoo ERP solves critical production issues through end-to-end process automation and real-time visibility. It helps manufacturers tackle key pain points in the manufacturing industry such as disconnected systems, manual errors, and lack of accurate data for decision-making.

-

Customization for Industry-Specific Needs

One of the major Odoo ERP benefits is its ability to support deep customization. Odoo can be tailored to meet sector-specific needs—such as integrating with manufacturing standards like PPAP, EMEA, APQP, CAPA, and advanced MRP systems. Through these industry-specific ERP solutions, Odoo supports discrete and process manufacturing, and batch production environments.

-

Powerful Features for Real-Time Operations

With robust Odoo ERP features for manufacturing, businesses can gain real-time control over production lines, automate order management, track inventory across multiple locations, and ensure quality with built-in checkpoints.

-

Proven Business Outcomes

From improved shop floor efficiency to higher CSAT scores and increased profit margins, Odoo ERP benefits in manufacturing are well documented. As a fully integrated, cloud-ready system, Odoo enables better collaboration and faster decision-making. No wonder more and more manufacturers are asking: Why do manufacturers choose Odoo ERP for operations? The answer lies in its ability to transform fragmented workflows into synchronized, agile, and data-driven processes.

Partnering with the Right Experts

Choosing the right technology is only half the battle—executing it effectively requires the guidance of a seasoned implementation partner like Navabrind IT Solutions.

As a trusted provider of Odoo ERP for manufacturing, Navabrind IT Solutions brings over a decade of experience delivering manufacturing ERP solutions tailored to unique industry needs. We don’t just implement software—we partner with manufacturers to transform how they operate, helping them solve persistent pain points in the manufacturing industry with AI-powered, future-ready ERP deployments.

Our expertise spans the entire ERP lifecycle. From strategic consulting and business process mapping to customization, integration, data migration, and post-implementation support, we offer end-to-end Odoo ERP implementation services. Whether you’re a discrete manufacturer needing advanced production scheduling, a batch producer aiming to streamline inventory management, or a process manufacturer focused on quality and compliance, Navabrind IT Solutions delivers.

Customization & Integration Expertise

Navabrind IT Solutions specializes in customizing the Odoo Manufacturing module to address production-specific challenges, such as automating BOM management, optimizing resource allocation, or integrating with third-party systems like PPAP, APQP, EMEA, CAPA, and MRP tools. This approach enables manufacturers to eliminate hurdles and unify their operations.

Solving Real Manufacturing Problems

Our solutions are rooted in addressing real-world manufacturing problems—from poor visibility and production delays to excessive manual intervention and disconnected systems. We leverage powerful Odoo ERP features for manufacturing to help you streamline production planning, solve inventory management issues, and improve decision-making with real-time data.

Focused on ROI and Scalability

With over 300 successful Odoo ERP projects across global manufacturing firms, Navabrind IT Solutions ensures that every implementation delivers on key business metrics—faster turnaround times, reduced operational costs, higher CSAT scores, and improved profit margins. We believe Odoo is the best ERP for solving manufacturing bottlenecks, and we ensure it’s tailored to your operations, no matter how complex.

Frequently Asked Questions

1. What are the biggest pain points in manufacturing that Odoo ERP solves?

The manufacturing industry faces numerous operational challenges, from inventory mismanagement to production inefficiencies, which can hinder growth and profitability. Odoo ERP for manufacturing is designed to address these pain points in the manufacturing industry by providing an all-in-one manufacturing ERP solution. Key issues it resolves include poor inventory tracking, production delays, cost overruns, manual data errors, and supply chain disruptions. By leveraging the Odoo Manufacturing Module, businesses gain real-time visibility into their operations.

A critical challenge in manufacturing solved by Odoo ERP is inefficient inventory control. Without proper systems, manufacturers often struggle with stockouts, excess inventory, or misplaced materials. Odoo ERP features for manufacturing eliminate these problems through automated stock alerts, batch/lot tracking, and integrated procurement tools, ensuring optimal inventory levels. Additionally, the system’s production planning capabilities help manufacturers avoid hurdles by aligning resources with demand.

Another major pain point in manufacturing is lack of cost control, where unexpected expenses or material waste eat into profits. Odoo ERP benefits manufacturers by providing accurate Bill of Materials (BOMs), real-time cost tracking, and waste analysis tools, helping businesses maintain tighter budgets. The ERP software for production issues integrates with accounting and CRM modules, eliminating manual data transfers and reducing errors. For manufacturers looking to streamline production planning with Odoo ERP, the platform offers drag-and-drop scheduling, shop floor management, and predictive maintenance features—making it one of the best ERPs for the manufacturing industry.

2. How does Odoo improve inventory management for manufacturers?

Effective inventory management is a cornerstone of successful manufacturing, yet many businesses struggle with stock inaccuracies, supply chain gaps, and inefficient replenishment processes. Odoo ERP for manufacturing tackles these pain points by offering a comprehensive inventory management system that enhances visibility, automation, and control. As a leading ERP for the manufacturing industry, Odoo provides tools like real-time stock tracking, multi-warehouse management, and automated reorder rules, ensuring manufacturers always have the right materials at the right time.

One of the standout Odoo ERP features for manufacturing is its ability to track inventory across multiple locations while minimizing manual intervention. The system supports barcode scanning, serial/lot number tracking, and cycle counting, reducing errors caused by human input. For businesses wondering how Odoo helps manufacturers optimize stock levels, the answer lies in its dynamic replenishment strategies. The software analyzes demand patterns, lead times, and supplier performance to generate smart purchase recommendations, preventing both shortages and overstocking.

Beyond basic stock control, the Odoo Manufacturing module goes further by integrating inventory with production and procurement. This means purchase orders are automatically generated when stock reaches predefined thresholds, and production schedules adjust based on material availability. Such streamlining of production planning with Odoo ERP not only cuts delays but also reduces carrying costs. Manufacturers dealing with global supply chains benefit from vendor portals and dropshipping automation, making Odoo a top choice for solving manufacturing challenges.

3. Can Odoo Reduce Production Downtime?

Production downtime is one of the most critical pain points in the manufacturing industry, leading to delayed orders, lost revenue, and operational inefficiencies. Odoo ERP for manufacturing directly addresses this challenge through its advanced Odoo manufacturing module, which includes preventive maintenance schedules, automated work orders, and real-time machine monitoring. These Odoo ERP features for manufacturing enable businesses to transition from reactive troubleshooting to proactive maintenance, significantly reducing unplanned stoppages. By leveraging manufacturing ERP solutions like Odoo, companies can ensure their equipment operates at peak efficiency.

One of the key ways Odoo helps manufacturers reduce downtime is through its predictive maintenance capabilities. The system tracks equipment usage and automatically schedules maintenance before failures occur, preventing costly production halts. Additionally, the Odoo Manufacturing Module provides shop floor dashboards that give managers instant visibility into machine performance, allowing them to quickly identify and resolve issues. This level of operational transparency is why many consider Odoo the best ERP for solving manufacturing bottlenecks, particularly where equipment reliability is crucial.

Beyond maintenance, Odoo ERP for Manufacturing streamlines production workflows to eliminate delays caused by manual processes. The software automates work order creation and resource allocation, ensuring that tasks are assigned efficiently and production lines keep moving. For manufacturers looking to streamline production planning with Odoo ERP, the platform’s Gantt charts and drag-and-drop scheduling tools make it easy to optimize timelines and reduce idle time. These Odoo ERP benefits collectively contribute to smoother operations, making it a top choice for businesses seeking to solve top manufacturing challenges with Odoo ERP.

4. Does Odoo Help Control Manufacturing Costs?

Controlling costs is a major concern in the manufacturing industry, where unexpected expenses—such as material waste, production inefficiencies, and supply chain delays—can quickly erode profits. Odoo ERP for Manufacturing provides robust tools to tackle these challenges in manufacturing solved by ERP, including accurate Bill of Materials (BOMs), real-time cost tracking, and waste analysis reports. These Odoo ERP features for manufacturing empower businesses to maintain tighter budgets, reduce waste, and improve overall profitability. By implementing Manufacturing ERP Solutions like Odoo, companies gain better visibility into their expenses.

A standout feature of Odoo ERP for Manufacturing is its ability to track material usage and waste at every stage of production. The system compares actual consumption against projected BOMs, flagging discrepancies that could indicate inefficiencies or theft. This level of detail is invaluable for manufacturers looking to control manufacturing costs with ERP software. Additionally, Odoo’s cost analysis reports break down expenses by product, department, or production line, helping businesses identify areas for improvement. These capabilities explain why manufacturers choose Odoo ERP for operations, as it provides the financial insights needed to stay competitive in a tight market.

Beyond material costs, Odoo helps manufacturers reduce overhead by automating manual processes that often lead to errors and rework. The software integrates seamlessly with accounting, procurement, and inventory management, eliminating redundant data entry and ensuring accurate financial records. For businesses struggling with supply chain cost overruns, Odoo’s vendor management tools and purchase automation help negotiate better terms and avoid rush-order premiums.

5. How Does Odoo Handle Complex Production Scheduling?

Complex production scheduling is one of the most persistent pain points in the manufacturing industry, where inefficient planning leads to missed deadlines, resource conflicts, and costly delays. Odoo ERP for Manufacturing rises to this challenge with its comprehensive suite of Odoo ERP features for manufacturing, including intuitive drag-and-drop planning, visual Gantt charts, and real-time shop floor control. These Manufacturing ERP Solutions empower businesses to create optimized schedules that account for machine availability, workforce capacity, and material requirements.

A key advantage of the Odoo Manufacturing Module is its ability to dynamically adjust schedules when unexpected changes occur. Whether it’s a machine breakdown, a delayed shipment, or a rush order, the system recalculates timelines and redistributes resources to minimize disruption. This agility is why many consider Odoo the best ERP for solving manufacturing bottlenecks, particularly in industries with volatile demand or custom production requirements. The software also provides conflict detection alerts, ensuring that managers can proactively address scheduling issues before they impact delivery dates. For manufacturers wondering how Odoo helps manufacturers maintain efficiency in complex environments, this intelligent scheduling capability provides a compelling answer.

Beyond day-to-day operations, Odoo ERP for Manufacturing offers advanced tools for long-term production planning. The system’s capacity planning features allow businesses to forecast future workloads and make informed decisions about equipment purchases or staff hiring. Additionally, integration with other modules like inventory management and purchasing means that production schedules automatically adjust based on material availability. These Odoo ERP benefits make it possible to solve top manufacturing challenges with Odoo ERP, from last-minute order changes to seasonal demand fluctuations. By providing both macro-level visibility and micro-level control, Odoo delivers the flexibility that modern manufacturers need.

6. Is Odoo Suitable for Small Manufacturers or Only Large Enterprises?

A common misconception about ERP for Manufacturing Industry solutions is that they’re only viable for large corporations with extensive IT budgets. However, Odoo ERP for Manufacturing breaks this mold by offering scalable solutions that cater to both small manufacturers and large enterprises. Small factories can start with basic Material Requirements Planning (MRP) functionality to manage their core operations, while larger organizations can expand into advanced modules like Product Lifecycle Management (PLM) and Quality Management. This flexibility is a key reason why manufacturers choose Odoo ERP for operations, regardless of their size or complexity.

For small manufacturers dealing with pain points in the manufacturing industry like manual inventory tracking or disjointed processes, Odoo Manufacturing Module provides an affordable yet powerful solution. The software’s user-friendly interface and modular design allow businesses to implement only what they need initially, then add features as they grow. This approach makes Odoo ERP benefits accessible even to companies with limited technical resources. Meanwhile, the system’s cloud deployment options eliminate the need for expensive hardware investments, further lowering the barrier to entry for smaller players in the manufacturing ERP solutions market.

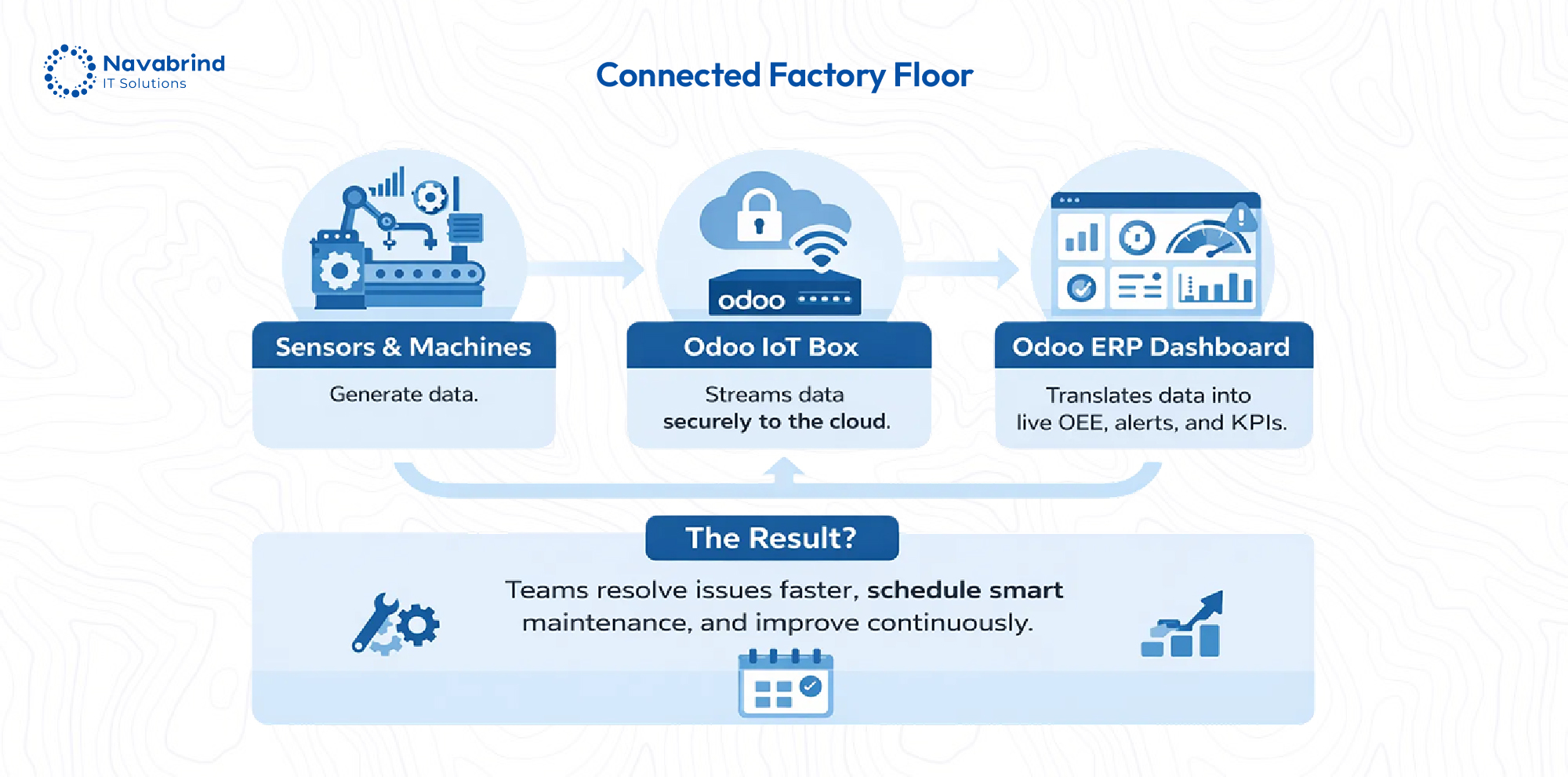

At the enterprise level, Odoo helps manufacturers tackle sophisticated challenges through its advanced Odoo ERP features for manufacturing. Large-scale operations can leverage multi-plant coordination, intercompany transactions, and IoT integrations to manage complex supply chains and global production networks. The platform’s open API architecture also allows seamless connectivity with legacy systems and specialized equipment, making it ideal for manufacturers looking to solve top manufacturing challenges with Odoo ERP in highly technical environments. Whether it’s a startup machine shop or a multinational industrial manufacturer, Odoo’s scalable framework proves it’s truly the best ERP for solving manufacturing bottlenecks across the entire spectrum of business sizes.

Schedule a conversation with us now!

Vasanth Anantharaman

Related Articles

-

Post

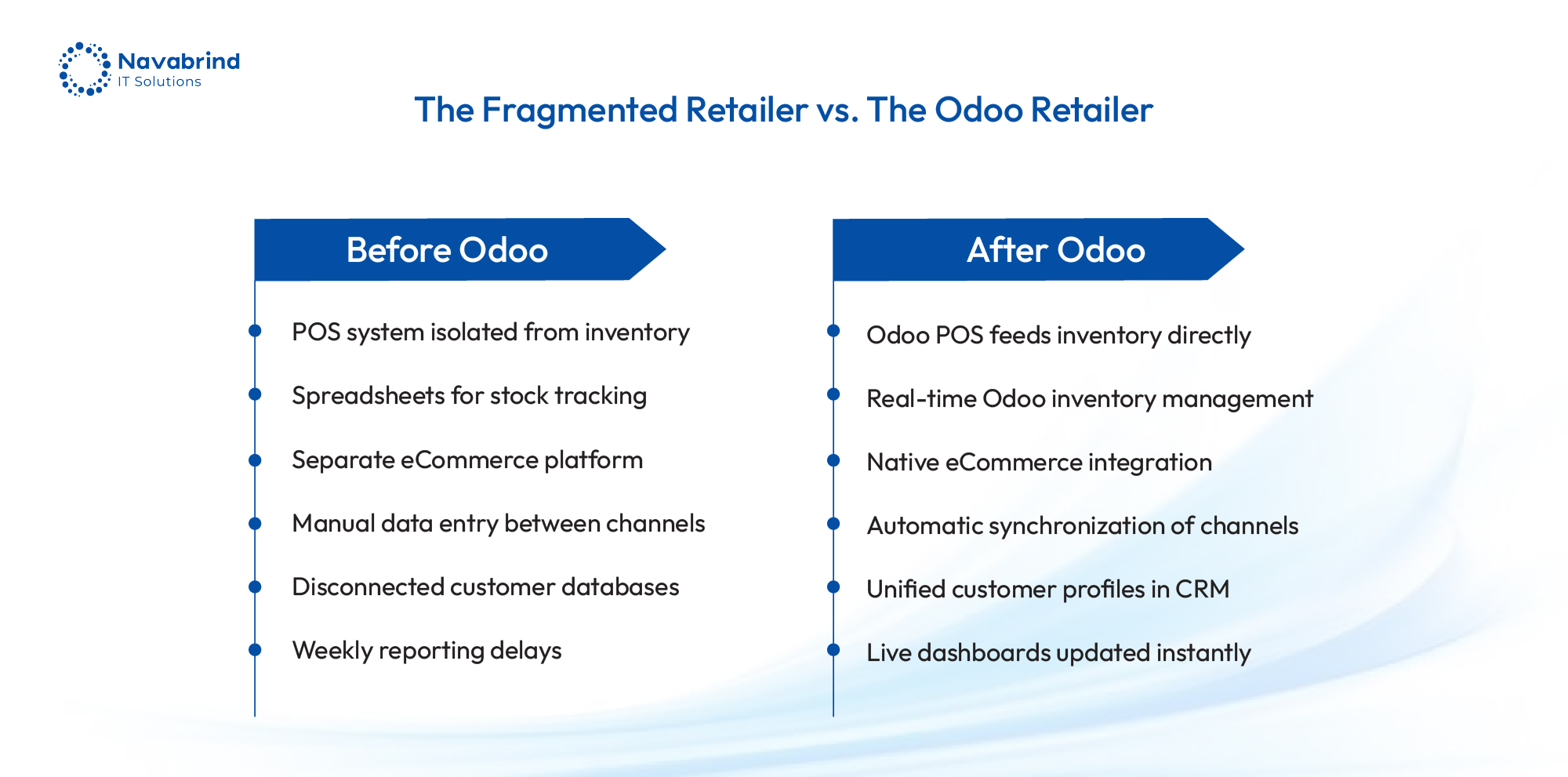

Odoo ERP for the Retail Industry: Driving Efficiency and Growth

Odoo ERP for the Retail Industry: Driving Efficiency and Growth February 27, 2026 Posted by: Vasanth Anantharaman Categories: Blog, Odoo for Retail industry No Comments Why the Retail Industry Runs Better on Odoo ERP Retail runs on dozens of disconnected apps. One tool for sales, another for stock, a third for loyalty. None speak to -

Post

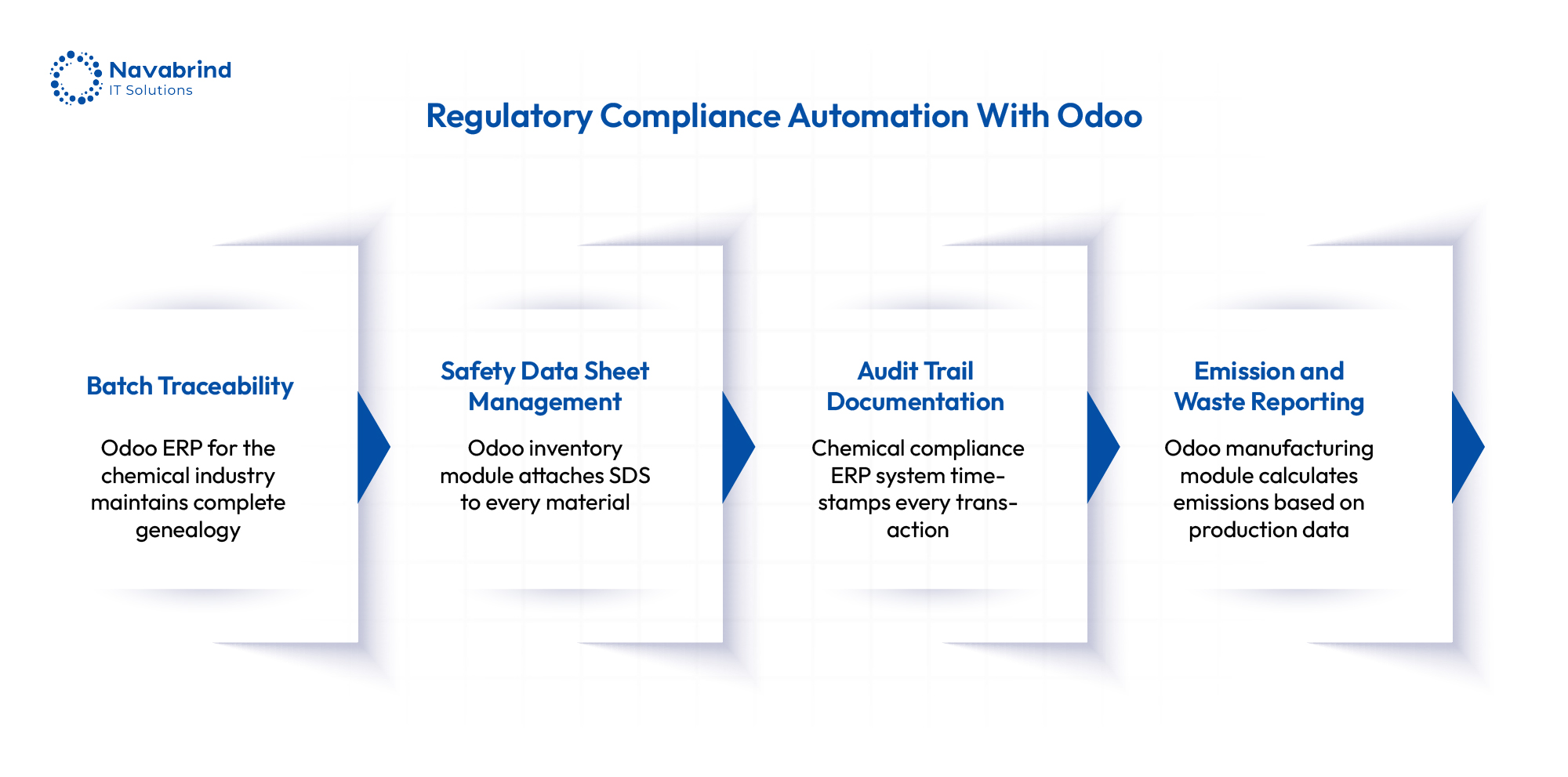

From Formula to Forecast: Odoo’s Transformative Edge in Chemical Manufacturing

From Formula to Forecast: Odoo’s Transformative Edge in Chemical Manufacturing February 27, 2026 Posted by: Jaishree Jayabal Singh Categories: Blog, Odoo ERP for Chemical Industry No Comments Odoo ERP for Chemical Industry Solves the Disconnection Problem Chemical manufacturing operates across multiple fronts, production floors, warehouse storage, laboratory testing, and regulatory reporting. Managing these as isolated -

Post

How Odoo ERP Helps Manufacturers Track Machine Efficiency and Move Toward Industry 4.0

How Odoo ERP Helps Manufacturers Track Machine Efficiency and Move Toward Industry 4.0 February 25, 2026 Posted by: Venkadesh Nagarajan Category: Uncategorized No Comments The Shift Toward Smart Manufacturing Machine efficiency is the core of manufacturing. Without it, cost control and scalability are impossible. Industry 4.0 accelerates this, merging IoT and data analytics to drive

Vasanth Anantharaman

How can we help you?

Get in touch with a solutions consultant that can share best practices and help solve specific challenges.