The Importance of Real-Time Data Management for Manufacturers Using Odoo ERP

- January 10, 2025

- Posted by: Vasanth Anantharaman

- Categories: Blog, Odoo

Manufacturing businesses create massive amounts of data. A large factory floor can generate over 1TB of production data each day. Many manufacturers still struggle to capture and use this valuable information properly.

Our firsthand experience with this challenge leads us to suggest Odoo ERP to our clients. Years of implementing Odoo ERP for manufacturers has taught us that up-to-the-minute data management isn’t optional – modern manufacturing operations depend on it. Manufacturers who use these data systems see their operational efficiency improve by up to 25%.

This blog post shows how to employ Odoo ERP for manufacturers and turn raw data into insightful information. You’ll learn about the key parts of real-time data management, practical steps to implement it, and proven ways to improve your production processes.

Understanding Real-Time Data in Manufacturing Operations

Real-time data forms the backbone of modern manufacturing operations and manufacturers need information that becomes available right after collection. Quick access to this data helps make informed decisions to keep production lines running smoothly.

Components of Real-Time Data in Manufacturing

Real-time data management focuses on three core components: velocity, volume, and variety. IoT sensors are a vital part of collecting this data. These sensors measure temperature, pressure, light and vibration patterns. Data is also collected from the very many departments that generate all types of forms be it text, numbers, visuals or other.

Key Data Points in Manufacturing Processes

Manufacturing operations track several essential metrics:

- Machine utilization and performance tracking

- Production throughput measurements

- Quality control metrics

- Energy consumption patterns

- Real-time inventory levels

These metrics help identify and resolve issues before they become problems. A machine’s underperformance triggers immediate alerts in our monitoring systems.

Role of Odoo ERP in Data Collection

Odoo ERP has proven its ability to streamline data collection and management. The system tracks inventory levels live as items move between locations, giving us accurate, current information about our stock levels.

Odoo’s manufacturing module integrates smoothly with other components. It can monitor quality control and production efficiency simultaneously. The system’s robust reporting and analytics tools help manufacturers make decisions based on analytical insights.

The system’s automation capabilities reduce manual tasks significantly. Users get instant access to critical business information – inventory levels, sales data, and customer figures. These features make Odoo ERP for manufacturers a great tool.

How Odoo ERP improves real-time data management in manufacturing

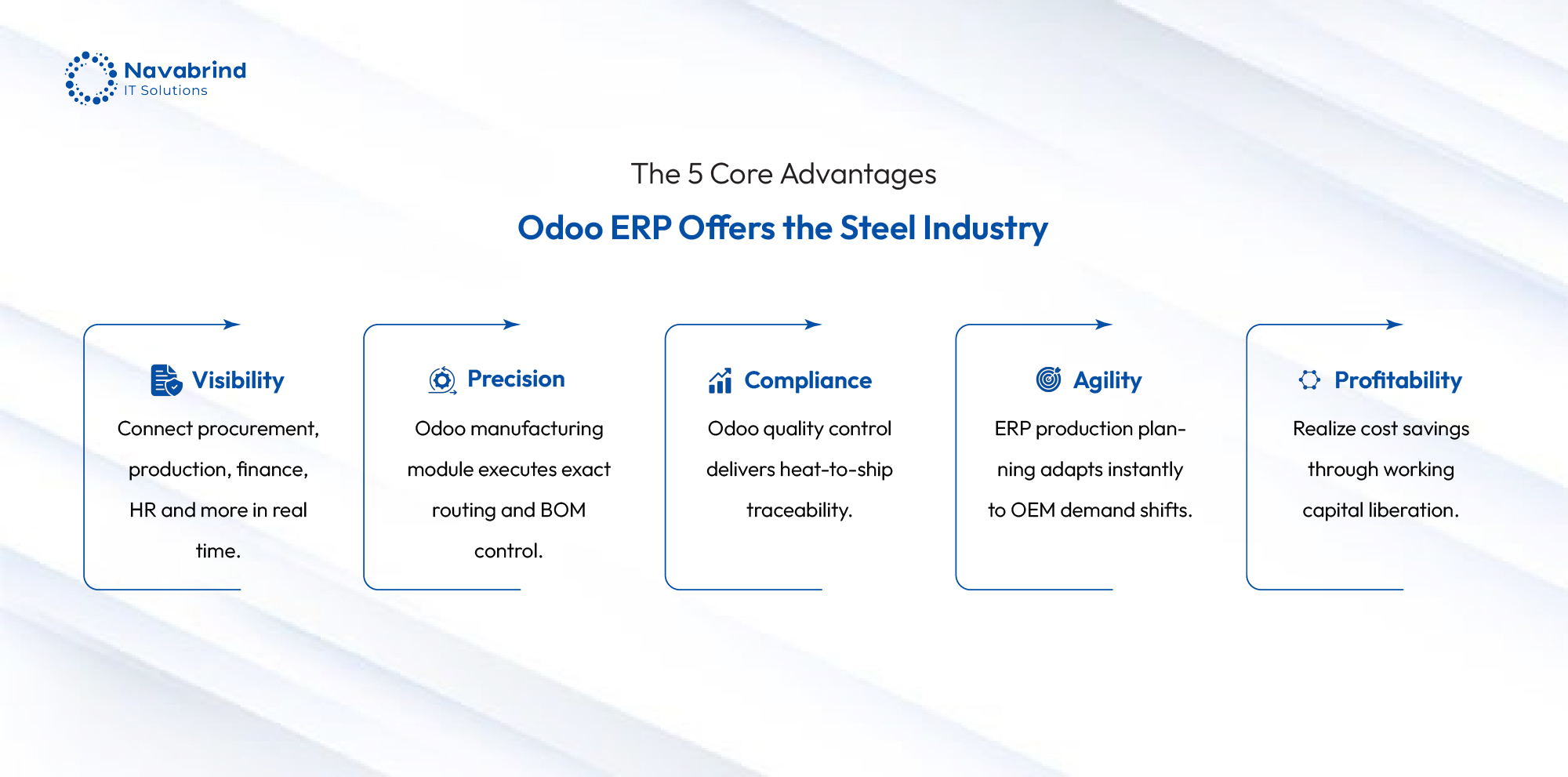

Odoo ERP enhances real-time data management by providing a single, centralized platform that integrates all aspects of a manufacturing business, from production planning and inventory to quality control and supply chain management. Unlike traditional ERP systems, which often operate in silos, Odoo’s modular yet interconnected architecture ensures that every department works from a unified data source. This eliminates discrepancies and ensures decision-makers have access to accurate, up-to-the-minute information.

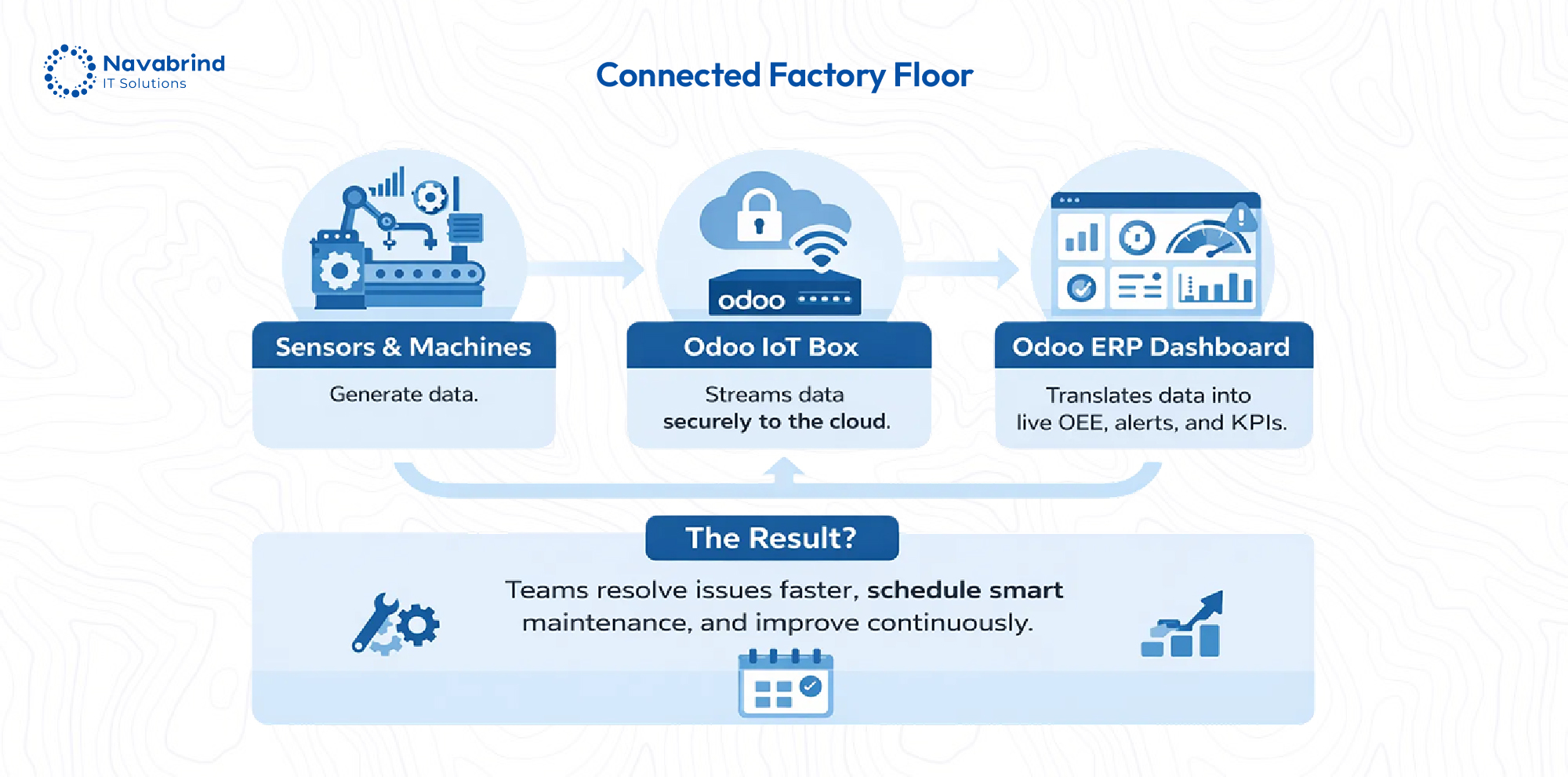

One of Odoo’s standout features is its IoT integration. By connecting IoT-enabled devices on the shop floor, Odoo captures critical machine data such as uptime, downtime, energy consumption, and production rates in real time. This data is then processed and displayed on dynamic dashboards accessible across departments. For instance, production managers can monitor the status of each machine in real time and immediately respond to inefficiencies or breakdowns, reducing downtime significantly.

Odoo also improves traceability by tracking the entire production lifecycle. From raw material procurement to finished goods delivery, each step is recorded in real-time, ensuring manufacturers can pinpoint the source of any issue quickly. Additionally, open-source Odoo ERP has built-in automation features that enable seamless data synchronization across modules, such as updating inventory levels automatically when raw materials are consumed in production. This level of real-time data management reduces manual errors, increases operational efficiency, and allows for faster, data-driven decision-making.

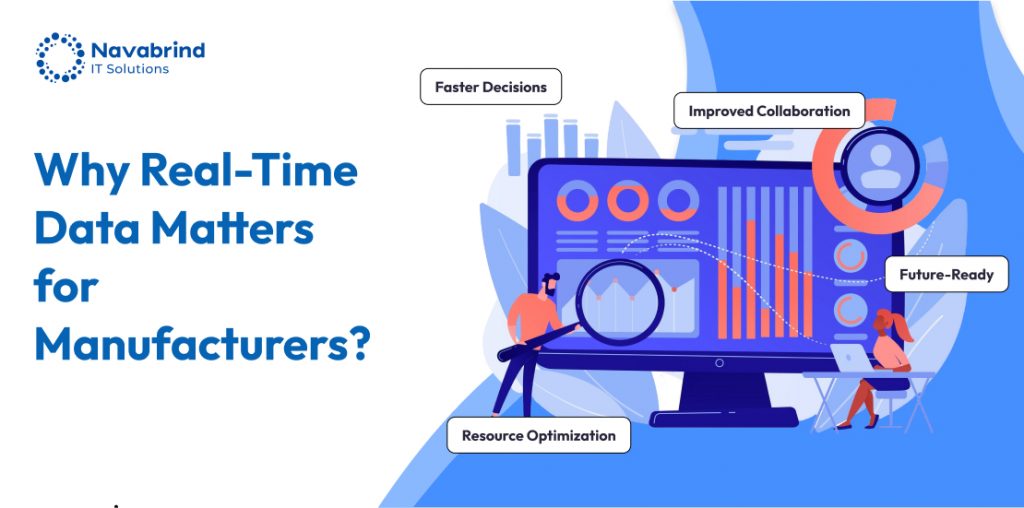

Benefits of real-time data management for manufacturing industries using Odoo

Odoo ERP for manufacturers offers significant benefits by enabling users to stay competitive in an increasingly data-driven world.

- Enhanced Operational Visibility: Real-time data management lets manufacturers gain a 360-degree view of their operations. For instance, Odoo provides live updates on raw material availability, machine utilization, and production schedules. This visibility enables businesses to anticipate potential bottlenecks and address them proactively. Such transparency ensures better coordination between departments.

- Faster and Informed Decision-Making: In manufacturing, delays in decision-making can have cascading effects, leading to missed deadlines and financial losses. Odoo’s ability to deliver real-time data across all modules, including sales, production, and procurement, ensures decision-makers have accurate information. For example, a sudden spike in demand can trigger immediate adjustments to production schedules and raw material orders, ensuring customer expectations are met without delays.

- Improved Quality Assurance and Compliance: Quality control is critical in manufacturing, and real-time data plays a vital role in maintaining high standards. Odoo’s quality module tracks every stage of production, instantly flagging deviations from set parameters. This ensures defects are identified and rectified quickly, minimizing waste and improving product consistency. Real-time data simplifies regulatory compliance by maintaining accurate records of materials used, processes followed, and certifications obtained.

- Inventory Optimization: As a manufacturing ERP, real-time inventory tracking is a game-changer. Odoo updates stock levels instantly as materials are consumed or products are finished. Inventory tracking helps manufacturers maintain optimal inventory levels, and prevent overstocking and stockouts. Automated reordering based on live data ensures that production lines remain uninterrupted, even during peak demand periods.

- Cost Efficiency and Waste Reduction: With real-time insights into machine performance and resource utilization, Odoo as manufacturing ERP identifies areas of inefficiency. For example, monitoring energy consumption in real time can highlight opportunities to reduce energy costs. Accurate production tracking minimizes waste by aligning output with demand and reducing surplus production.

- Regulatory Compliance Made Easier: Manufacturing industries often operate under strict regulatory frameworks. Odoo’s real-time data management ensures complete traceability of production processes and materials, simplifying audits and certifications. This not only ensures compliance but also builds trust with customers and stakeholders.

Implementing Real-Time Data Management Systems

For a manufacturing ERP, data collection in real time is vital, and the Internet of Things (IoT) plays a key role in turning traditional factories into smart manufacturing units.

Setting Up Data Collection Points

Accurate data collection depends on strategic sensor placement. Place sensors as close as possible to output points. The data collected can include:

- Machine status and performance metrics

- Production cycle times

- Quality control parameters

- Energy consumption data

- Environmental conditions

Configuring Odoo Sensors and IoT Devices

Odoo ERP for manufacturers showed that the ERPs IoT module works well in collecting data from devices of all types. Use an IoT box, a microcomputer device that connects multiple inputs through USB, Bluetooth, HDMI, and Wi-Fi. This setup helps monitor machine performance and track inventory levels live.

Leveraging Real-Time Analytics for Production Optimization

Odoo ERP for manufacturing shows how immediate analytics can improve production efficiency. Their manufacturing module offers clear visibility into production lines and allows users to track productivity, throughput, and cycle times.

Monitoring Production Metrics in Real-Time

The monitoring systems track important production metrics. Core focus areas include:

- Machine utilization rates

- Production yield percentages

- Equipment performance indicators

- Quality control measurements

- Cycle time variations

The Odoo maintenance module supports predictive and preventive maintenance strategies. It tracks equipment’s performance and repair histories.

Identifying and Resolving Bottlenecks

Advanced analytics help users spot production bottlenecks before they affect operations. Systems in the manufacturing ERP find inefficiencies in production, inventory, and maintenance. By analyzing equipment failure patterns, users can tackle potential issues early.

Optimizing Resource Allocation

Resource optimization presents complex challenges, but as a manufacturing ERP Odoo has created effective strategies that improve workforce performance while staying within budgets and timelines. Performance metrics guide resource allocation decisions. Regular assessment of equipment, personnel, and materials helps users find areas of excess or shortage. This analytical approach enables informed decisions about resource distribution. These optimization strategies have led users to experience notable improvements in their manufacturing processes. Teams now monitor performance indicators, track production efficiency, and find areas for improvement through customizable dashboards.

Ensuring Data Accuracy and Security

Data protection matters as much as data collection in today’s digital manufacturing world. Odoo ERP for manufacturers is high on security measures and aligns with precise data collection.

Data Validation Protocols

Validation protocols safeguard data integrity throughout the manufacturing process. The validation system we built has the following:

- Immediate data verification

- Automated error detection

- Cross-reference checking

- Quality control validation

- Input standardization

These protocols prevent data corruption that could disrupt operations significantly.

Security Measures for Real-Time Data

The security framework focuses on three vital areas:

- Data Encryption: Advanced encryption protects stored data and information in transit.

- Access Control: User roles and permissions align with job responsibilities.

- Regular Security Audits: Security assessments help us spot and fix potential vulnerabilities.

Users can maintain strict authentication protocols alongside these measures. Manufacturing ERP data needs protection from various threats because ransomware has become the leading cyber threat to manufacturing operations.

Backup and Recovery Systems

A backup strategy follows the industry-standard 3-2-1 rule:

- Three copies of critical data

- Two different storage media types

- One off-site backup location.

As a manufacturing ERP, Odoo performs automated backups at set intervals. This strategy works well since 30% of recovered tapes don’t work during critical moments. A disaster recovery plan ensures quick failover of essential workloads to keep operations running smoothly.

Efficiency is the cornerstone of successful manufacturing operations, and real-time data is pivotal. Odoo as a manufacturing ERP transforms raw, real-time data into actionable insights, enabling optimized processes for higher productivity.

Demand-Driven Production: Odoo ERP integrates live sales data with production planning, ensuring manufacturers produce precisely what is needed when it is required. This demand-driven approach reduces the risks of overproduction and unsold inventory. For example, a manufacturer can adjust production schedules in real time to align with sudden customer demand changes, avoiding shortages and excess stock.

Predictive Maintenance for Machines: Unplanned machine downtime can disrupt manufacturing operations. When integrated with IoT devices, Odoo ERP for manufacturers allows for monitoring equipment performance in real-time. Metrics such as vibration levels, temperature, and operating hours are analyzed to predict when a machine might require maintenance. By addressing potential issues before they escalate, manufacturers can reduce unplanned downtime, extend equipment lifespan, and save on maintenance costs.

Workflow Optimization:Identifying bottlenecks in real time is critical to maintain smooth operations. Odoo ERP provides live insights into production line performance, enabling managers to spot and address inefficiencies quickly. For example, if a particular production stage is slower than expected, resources can be reallocated immediately to resolve the issue and maintain overall workflow efficiency.

Labor Resource Management:Real-time data helps optimize labor allocation by providing insights into current workloads and production priorities. Odoo ERP for manufacturers ensures that labor resources are deployed efficiently, minimizing idle time and avoiding overburdening workers. For instance, if a high-priority order needs to be fulfilled, managers can reassign workers in real time to meet deadlines without compromising other operations.

Enhanced Collaboration Across Departments: Real-time data fosters better communication between departments, such as production, procurement, and sales. For instance, if a production delay occurs, the sales team is immediately informed and can manage customer expectations accordingly. This level of interdepartmental coordination enhances overall efficiency and customer satisfaction.

Data-Driven Continuous Improvement: Odoo’s ability to analyze real-time data over time gives manufacturers valuable insights for continuous improvement. Trends in machine performance, resource utilization, and production efficiency can be identified, allowing businesses to make strategic adjustments that drive long-term efficiency gains.

The Future Belongs to Manufacturers Who Adopt Real Time Data Management

Partnering with Navabrind IT Solutions enables manufacturers to fully leverage Odoo ERP for real-time data management, unlocking operational efficiency and cost savings. As an Odoo Gold Partner, we combine deep expertise in Odoo ERP implementation with delivering tailored solutions across industries. Our team ensures seamless integration of Odoo modules with IoT devices, custom workflows, and data-driven dashboards, empowering manufacturers to monitor operations in real time and make informed decisions. With a focus on aligning technology with business goals, we optimize Odoo for manufacturers, enabling predictive maintenance, inventory control, and production efficiency while reducing manual effort and errors. From consulting to deployment and support, Navabrind IT Solutions is the ideal partner to transform manufacturing operations through robust real-time data management powered by Odoo ERP.

Frequently Asked Questions

1.How does Odoo ERP improve real-time data management in manufacturing?

Odoo for manufacturers acts as the central nervous system of your operations, collecting, processing, and distributing data in real-time across your production ecosystem. Imagine having a tool that shows you exactly what’s happening on your shop floor, inventory, and supply chain – all at once! It seamlessly integrates various aspects of your manufacturing process, including:

- Inventory management

- Production planning

- Quality control

- Supply chain management

By centralizing data from these areas, Odoo ERP enables manufacturers to:

- Monitor production progress in real-time: Say goodbye to guesswork and hello to precise tracking!

- Identify bottlenecks instantly: Spot issues before they become major problems.

- Optimize resource allocation: Ensure your resources are always where they’re needed most.

2. Why is real-time data important for manufacturers using ERP systems?

In manufacturing, time is money, and information is power. Real-time data is the secret sauce that helps you confidently make split-second decisions. It’s like having a superpower that lets you see into the future of your production line!

Here’s why:

- Agility: Respond swiftly to market changes and customer demands.

- Accuracy: Make decisions based on up-to-the-minute information, not outdated reports.

- Efficiency: Eliminate time lags and reduce waste in your processes.

- Competitiveness: Stay ahead of the curve by adapting faster than your competitors.

Imagine being able to adjust your production schedule on the fly or reallocate resources instantly based on real-time demand. That’s the power of Odoo ERP!

3.What are the benefits of using Odoo ERP for real-time data processing in manufacturing?

Odoo ERP doesn’t just process data; it transforms it into your competitive edge. It’s like having a team of expert analysts working 24/7 to optimize your operations. Odoo for manufacturers, transforms data into actionable insights. Here are some key benefits:

Enhanced decision-making: Make informed choices based on real-time analytics and reports.

Improved quality control: Detect and address quality issues immediately, reducing defects and recalls.

Increased productivity: Streamline workflows and automate routine tasks, freeing up your team to focus on value-added activities.

Better customer satisfaction: Meet delivery deadlines consistently and respond quickly to customer inquiries.

4. How does Odoo ERP integrate real-time data across various manufacturing functions?

Odoo ERP for manufacturers is the ultimate multitasker, seamlessly connecting every aspect of your manufacturing process. It’s like having a universal translator who ensures all your departments speak the same language.

Production floor: Real-time updates on machine status, production progress, and work orders.

Inventory: Instant visibility into stock levels, reorder points, and material movements.

Supply chain: Live tracking of supplier deliveries and order statuses.

Quality control: Immediate flagging of quality issues and initiation of corrective actions.

Sales and customer service: Up-to-date information on production capacity and delivery timelines.

This integration ensures that everyone in your organization is on the same page and working with the most current information.

5.How can real-time data management with Odoo ERP reduce operational costs for manufacturers?

Odoo ERP for manufacturers reduces operational costs by providing real-time insights that streamline processes, eliminate inefficiencies, and optimize resource utilization. Here’s how:

Minimized Downtime: Odoo ERP integrates with IoT-enabled machines to track performance metrics like vibration and temperature, enabling predictive maintenance. This reduces unplanned downtime and extends the machine’s lifespan.

Inventory Optimization: Real-time inventory tracking prevents overstocking and stockouts. Automated reordering and demand forecasting ensure just-in-time inventory, reducing carrying costs and waste.

Resource Allocation: Odoo ERP provides insights into labor and machine utilization, enabling efficient resource distribution. This minimizes idle time and labor inefficiencies.

Streamlined Production: Real-time visibility into workflows helps identify bottlenecks. Managers can adjust schedules or reallocate resources to accelerate production and lower delays.

Quality Control: Odoo tracks quality metrics in real time, allowing immediate detection and resolution of defects. This reduces waste and rework costs while improving product quality.

Energy Savings: Real-time monitoring identifies energy-intensive operations, enabling manufacturers to optimize equipment usage and reduce utility costs.

Procurement Efficiency: Integrated procurement and inventory data eliminate costly emergency purchases and improve supplier negotiations with accurate forecasting.

Automation: Odoo ERP automates tasks like inventory tracking and report generation, reducing manual errors and operational inefficiencies.

6.Can Odoo ERP support predictive maintenance using real-time data in manufacturing?

Yes, Odoo ERP for manufacturers supports predictive maintenance by leveraging real-time data to monitor machine performance and anticipate potential issues before they occur. Predictive maintenance reduces downtime, extends equipment lifespan, and lowers maintenance costs—key benefits for manufacturers striving for operational efficiency.

IoT Integration for Real-Time Monitoring: Odoo ERP for manufacturers integrates IoT-enabled devices on the shop floor to track critical metrics such as temperature, vibration levels, and operating hours. This data is continuously collected and analyzed to identify anomalies and patterns that indicate potential equipment failures.

Dynamic Maintenance Scheduling:Using real-time data, Odoo ERP for manufacturers enables dynamic scheduling of maintenance activities. Instead of following fixed maintenance intervals, manufacturers can act based on the actual condition of machinery, optimizing maintenance resources and reducing unnecessary downtime.

Improved Resource Allocation:Real-time insights from Odoo allow manufacturers to plan resources effectively. For example, maintenance teams can focus on high-risk equipment while minimizing disruptions to production schedules.

Cost Savings and Efficiency: Predictive maintenance supported by Odoo ERP for manufacturers reduces costs by minimizing emergency repairs, avoiding unplanned production halts, and extending the life of critical assets. Manufacturers can also optimize spare parts inventory, ensuring parts are available when needed without overstocking.

Schedule a conversation with us now!

Related Articles

-

Post

How Odoo ERP Helps Manufacturers Track Machine Efficiency and Move Toward Industry 4.0

How Odoo ERP Helps Manufacturers Track Machine Efficiency and Move Toward Industry 4.0 February 25, 2026 Posted by: Venkadesh Nagarajan Category: Uncategorized No Comments The Shift Toward Smart Manufacturing Machine efficiency is the core of manufacturing. Without it, cost control and scalability are impossible. Industry 4.0 accelerates this, merging IoT and data analytics to drive -

Post

How Odoo ERP Drives Efficiency in the Steel Industry

How Odoo ERP Drives Efficiency in the Steel Industry February 18, 2026 Posted by: Tony Categories: Blog, Odoo No Comments The High-Stakes Race of Auto Parts Manufacturing Your OEM demands a production schedule shift, but procurement can’t confirm steel availability. The sales team lacks real-time inventory data for a quote and your shop floor operates -

Post

Odoo Database Migration Guide: From Homegrown Retail ERP to Odoo ERP Without Downtime

Odoo Database Migration Guide: From Homegrown Retail ERP to Odoo ERP Without Downtime February 18, 2026 Posted by: Tony Category: Uncategorized No Comments The Need for Smooth Odoo Database Migration If your outdated software, disparate applications, and an unsupported ERP begin to hinder work, you are no longer dealing with a minor technical issue, but

How can we help you?

Get in touch with a solutions consultant that can share best practices and help solve specific challenges.