How Odoo ERP Simplifies Inventory Management for Manufacturers

- January 23, 2025

- Posted by: Vasanth Anantharaman

- Categories: Blog, Odoo

Effective Odoo ERP inventory management is at the heart of a successful manufacturing operation. Manufacturers, whether large, medium, or small, face unique challenges when it comes to tracking raw materials, managing stock levels, and ensuring timely production. Odoo ERP inventory management provides an all-in-one solution. In this blog post, we will explore how Odoo for manufacturers can transform how inventory is handled.

Odoo ERP inventory optimization is critical for manufacturers to balance supply and demand while minimizing costs. Advanced tools from Odoo for manufacturers help achieve this balance through:

- Demand Forecasting: Odoo analyzes historical data and sales trends to forecast demand, enabling manufacturers to plan inventory levels.

- Minimum Stock Rules: With Odoo, manufacturers can set minimum stock levels for each product. The system automatically triggers a replenishment order when stock falls below this threshold.

- Stock Transfers and Multi-Warehouse Management: Odoo ERP streamlines stock transfers and ensures efficient inventory distribution for manufacturers with multiple locations.

These features reduce carrying costs and improve production efficiency by ensuring that the right materials are available at the right time.

How Does Odoo Manufacturing Software Help Manage Inventory?

The most common question Navabrind IT Solutions, an Odoo implementation partner, hears is how Odoo helps manufacturers manage inventory. Inventory management in manufacturing involves much more than just keeping track of stock. Manufacturers must ensure that raw materials are available when needed, production schedules are adhered to, and finished goods are delivered on time. Odoo manufacturing software simplifies these tasks through its powerful inventory management tools.

Below are some points on how users can experience the benefits of Odoo for manufacturers.

Odoo ERP Implementation for Medium-Sized Businesses

Real-Time Inventory Tracking: Odoo for manufacturers provides real-time visibility into inventory levels, ensuring that manufacturers always know what materials are available and where they are located. This feature reduces the risk of stockouts or overstocking, enabling smoother production cycles and efficient resource allocation.

Automation of Key Processes: With Odoo, manufacturers can automate repetitive tasks such as stock replenishment, purchase order creation, and inventory adjustments. Automation minimizes manual intervention, reducing errors and saving valuable time. For instance, Odoo’s reordering rules automatically trigger purchase or manufacturing orders when stock levels fall below predefined thresholds, ensuring uninterrupted production.

Integration with Manufacturing Workflows: Odoo ERP inventory management integrates with manufacturing, sales, and procurement modules. This ensures that inventory updates are automatically reflected across all operations. For example, when raw materials are consumed during production, inventory levels are adjusted in real-time, providing accurate data for procurement planning and production scheduling.

Barcode Scanning and Serial Number Tracking: Odoo for manufacturers supports barcode scanning and serial number tracking, enhancing accuracy in inventory handling. This feature is especially beneficial for manufacturers with high-value or serialized products, as it ensures precise stock control and traceability.

Batch and Lot Tracking: Odoo’s batch and lot tracking capabilities provide full traceability for industries requiring strict compliance, such as food or pharmaceuticals. Manufacturers can track materials from procurement to finished goods, ensuring quality control and regulatory compliance.

Multi-Warehouse Management: Manufacturers with operations spanning multiple locations can use Odoo to efficiently manage stock transfers and maintain optimal inventory levels across warehouses. Odoo for manufacturers allows visibility into stock availability at each location, simplifying logistics and distribution.

Benefits of Using Odoo ERP for Inventory Management in Manufacturing

The benefits of adopting Odoo ERP inventory management for manufacturing extend beyond operational efficiency. Here are some key advantages:

Centralized Inventory Control: Odoo manufacturing software offers a unified platform to manage inventory across multiple warehouses and locations. This centralization ensures data consistency, reduces duplication, and minimizes errors, allowing manufacturers to maintain better control over stock levels and streamline logistics.

Improved Production Planning: With real-time inventory updates integrated into manufacturing workflows, Odoo lets manufacturers plan production schedules more accurately. Manufacturers can prevent disruptions, avoid delays, and maintain steady production lines by knowing exactly what materials are available and when additional supplies will arrive. This integration also enhances coordination between departments, fostering a cohesive production process.

Reduction in Manual Errors: Traditional inventory systems often involve manual data entry, leading to inaccuracies in stock levels, order processing, and inventory tracking. Odoo manufacturing software eliminates this risk through automation. Tasks such as updating stock levels, generating purchase orders, and tracking shipments are automated, ensuring higher accuracy and freeing staff to focus on strategic tasks.

Data-Driven Decision-Making: One of Odoo’s standout features is its robust analytics and reporting tools. These tools provide manufacturers with detailed insights into inventory performance, including turnover rates, stock valuation, and demand patterns. With this data, manufacturers can make informed decisions on procurement, production planning, and inventory optimization. For example, manufacturers can identify slow-moving products and adjust purchasing strategies to reduce waste.

Cost Savings: Effective Odoo ERP inventory management translates directly into cost savings. Manufacturers can reduce carrying costs associated with excess stock by optimizing inventory levels. Automation reduces labor costs by minimizing the need for manual oversight. Improved inventory accuracy lowers the risk of production halts due to material shortages, further contributing to cost efficiency. For small manufacturers, these savings can make a significant impact on profitability.

Scalability for Growth: Odoo’s modular design allows manufacturers to scale their operations seamlessly. As businesses grow and expand into new markets, Odoo’s inventory management system can adapt to handle increasing stock complexity, additional warehouses, and new product lines. This scalability ensures that manufacturers can continue to rely on Odoo as their operations evolve.

Regulatory Compliance and Traceability: For manufacturers in regulated industries, such as pharmaceuticals or food production, Odoo for manufacturers provides essential tools for compliance. Features like batch tracking, lot numbers, and expiration date monitoring help manufacturers adhere to industry standards and ensure traceability throughout the supply chain. This not only safeguards quality but also builds trust with customers and partners.

Inventory Management for Small Manufacturers with Odoo ERP

Small manufacturers often face unique challenges in inventory management due to limited resources and budgets. Odoo ERP inventory management offers an affordable and scalable solution tailored to their needs.

Affordability: Odoo’s open-source nature makes it a cost-effective choice for small businesses. They can start with essential modules and add more as they grow.

Simplified Workflows: Odoo’s user-friendly interface and pre-configured workflows make it easy for small teams to adopt and use the system effectively.

Scalability for Growth: As small manufacturers expand, Odoo scales with them. Its modular architecture allows businesses to integrate additional features and modules without disrupting operations.

Enhanced Competitiveness: By leveraging advanced tools from Odoo manufacturing software, small manufacturers can compete with larger players by improving operational efficiency and customer satisfaction.

Resource Optimization: Odoo’s automation tools help small manufacturers make the most of limited resources, from inventory tracking to production scheduling. This ensures that even with smaller teams and budgets, operations run smoothly and efficiently.

Odoo ERP inventory management provides the perfect balance of functionality and affordability for small manufacturers looking to scale their operations.

Why Odoo ERP Stands Out for Manufacturing Inventory Management

Odoo ERP’s flexibility, scalability, and advanced features make it a standout choice for manufacturers seeking to optimize inventory management. Here’s why:

Flexibility Across Industries: Odoo’s customizable modules cater to diverse manufacturing sectors, including automotive, FMCG, e-commerce, and more.

Cloud-Based Deployment: Odoo’s cloud-based architecture allows remote access and mobile use, enabling manufacturers to manage inventory anytime.

Open-Source Customization: As an open-source platform, Odoo offers unparalleled customization options, allowing manufacturers to tailor the system to their unique needs.

These qualities position Odoo ERP as a transformative tool for manufacturers looking to stay competitive in an increasingly dynamic market.

To Wrap Up this blog post on Odoo ERP Inventory Management

Efficient inventory management is essential for manufacturers to meet customer demands, reduce costs, and maintain profitability. Odoo ERP inventory management provides a powerful solution to streamline operations, optimize inventory levels, and enhance decision-making. From small manufacturers to large enterprises, Odoo ERP’s manufacturing software and inventory tools cater to the unique needs of every business.

By integrating inventory with manufacturing, sales, and procurement workflows, Odoo empowers manufacturers to operate more efficiently and competitively. Whether you’re a small manufacturer looking to scale or an established player aiming to enhance efficiency, Odoo ERP offers the tools you need to succeed. Embrace Odoo ERP inventory optimization and take your manufacturing operations to the next level.

Frequently Asked Questions

1.How can Odoo ERP improve inventory management for manufacturers?

Odoo ERP inventory management streamlines and enhances inventory processes for manufacturers, enabling better control, accuracy, and efficiency. Here are the key ways it achieves this:

Real-Time Stock Visibility: Odoo ERP inventory optimization provides live updates on inventory levels, movements, and locations, ensuring manufacturers have accurate data to make informed decisions.

Automated Inventory Operations: Odoo ERP inventory management automates critical tasks like stock replenishment, order generation, and inventory adjustments, reducing manual errors and saving time.

Demand Forecasting: Leverages historical data and sales trends to predict inventory needs, ensuring optimal stock levels without overstocking or stockouts.

Integrated Supply Chain Management: Synchronizes inventory data with procurement, production, and sales modules, creating a unified workflow across departments and ensuring timely stock availability.

Barcode and IoT Integration: Simplifies inventory tracking with barcode scanning and IoT-enabled devices, ensuring accuracy and efficiency in stock handling processes.

Batch and Lot Tracking: Odoo manufacturing software enables users to track raw materials and finished goods at the batch or lot level, improving traceability and compliance with regulatory standards.

Multi-Warehouse Management: Allows seamless coordination across multiple warehouses, ensuring efficient stock transfers, optimized storage, and improved logistics.

Customizable Reporting and Dashboards: Offers detailed reports and visual dashboards that provide actionable insights into inventory performance and inefficiencies, helping manufacturers fine-tune their strategies.

Cost Reduction: Optimizes inventory levels to minimize carrying costs, reduce wastage, and prevent losses due to obsolescence or spoilage.

Scalability: Odoo for manufacturers adapts to users’ growing needs, allowing them to scale inventory operations as their business expands.

By leveraging Odoo ERP inventory management, manufacturers can achieve greater operational efficiency, reduce costs, and ensure a smoother production process, making it a vital tool for modern manufacturing businesses.

2. What are the key features of Odoo’s inventory management system for manufacturers?

Odoo for Manufacturers offers a robust inventory management system to streamline operations, reduce costs, and improve efficiency. Below are its standout features:

Real-Time Inventory Tracking: Use barcode scanning, serial number tracking, and IoT integration to gain instant visibility into stock levels, movements, and locations. This ensures accuracy and eliminates manual errors.

Automated Reordering: Define reorder rules based on demand forecasts and safety stock levels. Odoo automatically generates purchase or production orders to prevent overstocking and stockouts.

Batch and Lot Tracking: Track products and raw materials at the batch or lot level, enabling better traceability for compliance, quality control, and recall management.

Multi-Warehouse Management: Manage inventory across multiple warehouses and locations with ease. Odoo’s system allows seamless transfers, optimized storage, and efficient site coordination.

Demand Forecasting: Leverage historical data, sales trends, and seasonality to accurately predict inventory requirements, aligning supply with production and market demand.

Seamless Integration with Manufacturing Modules: Integrate inventory management with Odoo’s production planning and procurement tools to ensure smooth workflows and synchronized operations.

FIFO, LIFO, and Custom Valuation Methods: Support for multiple inventory valuation techniques allows manufacturers to align inventory accounting with business strategies.

Inventory Adjustments: Perform cycle counts, stock audits, and real-time inventory adjustments without disrupting operations.

Comprehensive Reporting and Dashboards: Access actionable insights through customizable dashboards and reports, enabling manufacturers to optimize inventory performance and identify inefficiencies.

Barcode Integration: Use barcode-enabled workflows to simplify stock operations like picking, packing, and inventory transfers for greater efficiency and accuracy.

Odoo for manufacturers empowers businesses to maintain optimal inventory levels, improve resource planning, and enhance operational efficiency, making it an ideal solution for modern manufacturing needs.

3.How does Odoo help reduce overstocking and stockouts in manufacturing?

Odoo manufacturing software helps manufacturers reduce overstocking and stockouts by providing real-time inventory visibility, automated workflows, and intelligent forecasting tools. It ensures that stock levels are continually optimized, aligning inventory with production needs and market demand. By centralizing inventory data and integrating it with procurement, production, and sales modules, Odoo enables manufacturers to make informed decisions and maintain just-in-time inventory.

The software’s demand forecasting capabilities analyze historical data, sales trends, and seasonality to accurately predict future needs. Based on these insights, manufacturers can set dynamic reorder points and safety stock levels, ensuring they always have the right amount of inventory without overburdening storage costs. If the stock falls below a certain threshold, Odoo manufacturing software can automatically trigger procurement or production orders, preventing stockouts and ensuring uninterrupted operations.

Odoo also integrates with IoT devices and barcode scanners, enabling real-time tracking of raw materials and finished goods across warehouses. This visibility minimizes discrepancies and helps manufacturers identify slow-moving or obsolete inventory. By focusing on high-demand items and reducing unnecessary stock, Odoo significantly cuts carrying costs and storage inefficiencies.

Additionally, the software’s reporting and analytics tools provide actionable insights into inventory performance.

Manufacturers can identify patterns, such as over-ordering specific materials or delayed stock movements, and adjust their strategies accordingly. With Odoo manufacturing software, businesses can streamline their supply chain, respond quickly to demand fluctuations, and achieve a balanced inventory—reducing the risk of overstocking and stockouts while enhancing operational efficiency and profitability.

4.Can Odoo ERP be integrated with existing manufacturing systems for inventory management?

Yes, Odoo ERP inventory optimization can be seamlessly integrated with existing manufacturing systems to enhance inventory management and operational efficiency. Odoo’s modular and API-driven architecture makes it highly adaptable, allowing manufacturers to connect it with various legacy systems, such as MES (Manufacturing Execution Systems), WMS (Warehouse Management Systems), and supply chain platforms. This integration enables a unified data flow across systems, ensuring real-time visibility into inventory levels, production workflows, and procurement activities.

Through Odoo’s integration capabilities, manufacturers can synchronize inventory data between Odoo ERP and existing systems without disrupting ongoing operations. For example, Odoo can pull data on raw material usage from MES systems and update stock levels in real time. Similarly, it can push demand forecasts and replenishment orders to supply chain platforms, automating procurement workflows. This interconnected approach minimizes data silos, reduces manual data entry, and ensures accurate inventory tracking.

Additionally, Odoo supports advanced features like barcode scanning, batch tracking, and serial number tracking, which can complement existing systems to streamline inventory processes. Manufacturers can implement Odoo ERP inventory optimization as a centralized hub while retaining specialized functions in their legacy systems. The flexibility of Odoo’s integration ensures that manufacturers can incrementally upgrade their inventory management capabilities without a complete system overhaul.

By integrating Odoo with existing manufacturing systems, manufacturers gain access to actionable insights and automated workflows, leading to improved resource planning, faster response times, and reduced operational costs. The scalability of Odoo also ensures that as business needs evolve, the ERP can adapt and grow alongside, making it a future-proof solution for inventory optimization in manufacturing environments.

5.How does Odoo ERP provide real-time inventory tracking for manufacturers?

Odoo manufacturing software offers comprehensive real-time inventory tracking capabilities, empowering manufacturers with instant visibility into their stock levels, movements, and usage. By using technologies like barcode scanning, serial number tracking, and integration with IoT-enabled devices, Odoo ensures that inventory data is updated in real-time as materials are consumed, products are manufactured, or shipments are dispatched. This eliminates the delays and inaccuracies often associated with manual inventory tracking, ensuring that manufacturers always have accurate stock data at their fingertips.

The software automates critical inventory processes, including stock replenishment, cycle counting, and internal transfers. With demand forecasting tools and intelligent reordering rules, manufacturers can maintain optimal inventory levels, avoiding both overstocking and stockouts. For example, if a specific raw material falls below a predefined threshold, Odoo can automatically generate a purchase order to replenish it. This level of automation minimizes human intervention, reduces errors, and ensures uninterrupted production.

Odoo’s real-time inventory tracking is seamlessly integrated with its procurement, production, and sales modules, creating a unified ecosystem for managing the entire supply chain.

Manufacturers can monitor raw materials, work-in-progress items, and finished goods in a single dashboard, gaining insights into stock availability across multiple warehouses or production sites. This integration enables manufacturers to align inventory with production schedules and customer demand, ensuring timely order fulfillment while reducing waste and inefficiencies.

Another advantage of Odoo manufacturing software is its ability to support advanced tracking techniques such as batch and lot tracking, which are particularly valuable in industries like food, pharmaceuticals, and electronics. Manufacturers can trace the movement of specific batches through the supply chain, ensuring compliance with regulations and enabling swift action in case of quality issues or recalls.

In conclusion, real-time inventory tracking with Odoo manufacturing software transforms inventory management from a reactive to a proactive process. By providing accurate, actionable insights into stock levels and movements, Odoo helps manufacturers reduce costs, improve operational efficiency, and enhance customer satisfaction through timely and reliable order fulfillment.

6. What are the benefits of using Odoo ERP for inventory optimization in manufacturing?

Using Odoo for manufacturers enables precise inventory optimization by providing real-time visibility into stock levels, demand forecasts, and supply chain movements. Odoo’s robust inventory management module automates key processes like stock tracking, reordering, and warehouse operations. With features like batch tracking and barcode scanning, manufacturers can reduce errors, prevent overstocking, and ensure just-in-time inventory management. This not only lowers carrying costs but also minimizes wastage caused by obsolete or expired materials, significantly improving operational efficiency.

Odoo for manufacturers seamlessly integrates inventory data with production schedules, procurement, and sales, ensuring smooth alignment across departments. Real-time data and automated workflows eliminate manual processes and silos, helping manufacturers respond quickly to changes in demand or disruptions in supply. By optimizing storage, transportation, and material usage, Odoo reduces costs while enhancing productivity and customer satisfaction. Whether for small manufacturers or large-scale operations, Odoo ERP provides the tools to build an agile, cost-efficient inventory system.

Schedule a conversation with us now!

Related Articles

-

Post

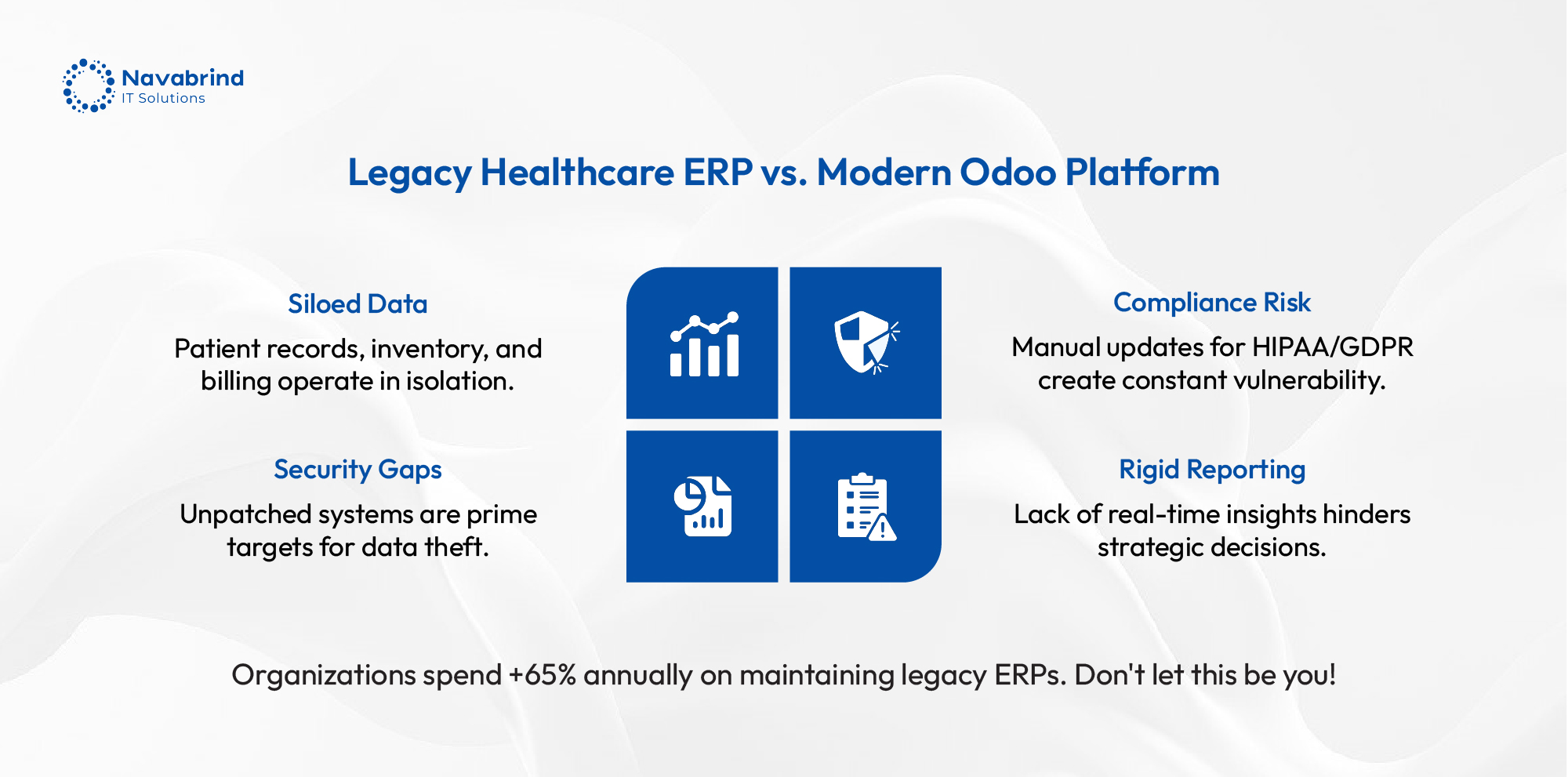

From Legacy Healthcare ERP to Odoo ERP: Why You Need Expert Odoo Migration Help

From Legacy Healthcare ERP to Odoo ERP: Why You Need Expert Odoo Migration Help February 11, 2026 Posted by: Tony Category: Uncategorized No Comments Why Healthcare Organizations Need Odoo ERP Migration Legacy healthcare ERP systems create barriers to efficiency. They are expensive to maintain, and struggle to integrate tools. This disconnect impacts patient care coordination, -

Post

From LLMs to Agentic AI: A Practical Guide to What They Mean and How to Choose

From LLMs to Agentic AI: A Practical Guide to What They Mean and How to Choose February 4, 2026 Posted by: Tony Categories: Artificial Intelligence, Blog No Comments As definitions, use cases, expectations, and investments around Large Language Models (LLMs), Retrieval-Augmented Generation (RAG), AI agents, and agentic AI continue to expand, many individuals and organizations -

Post

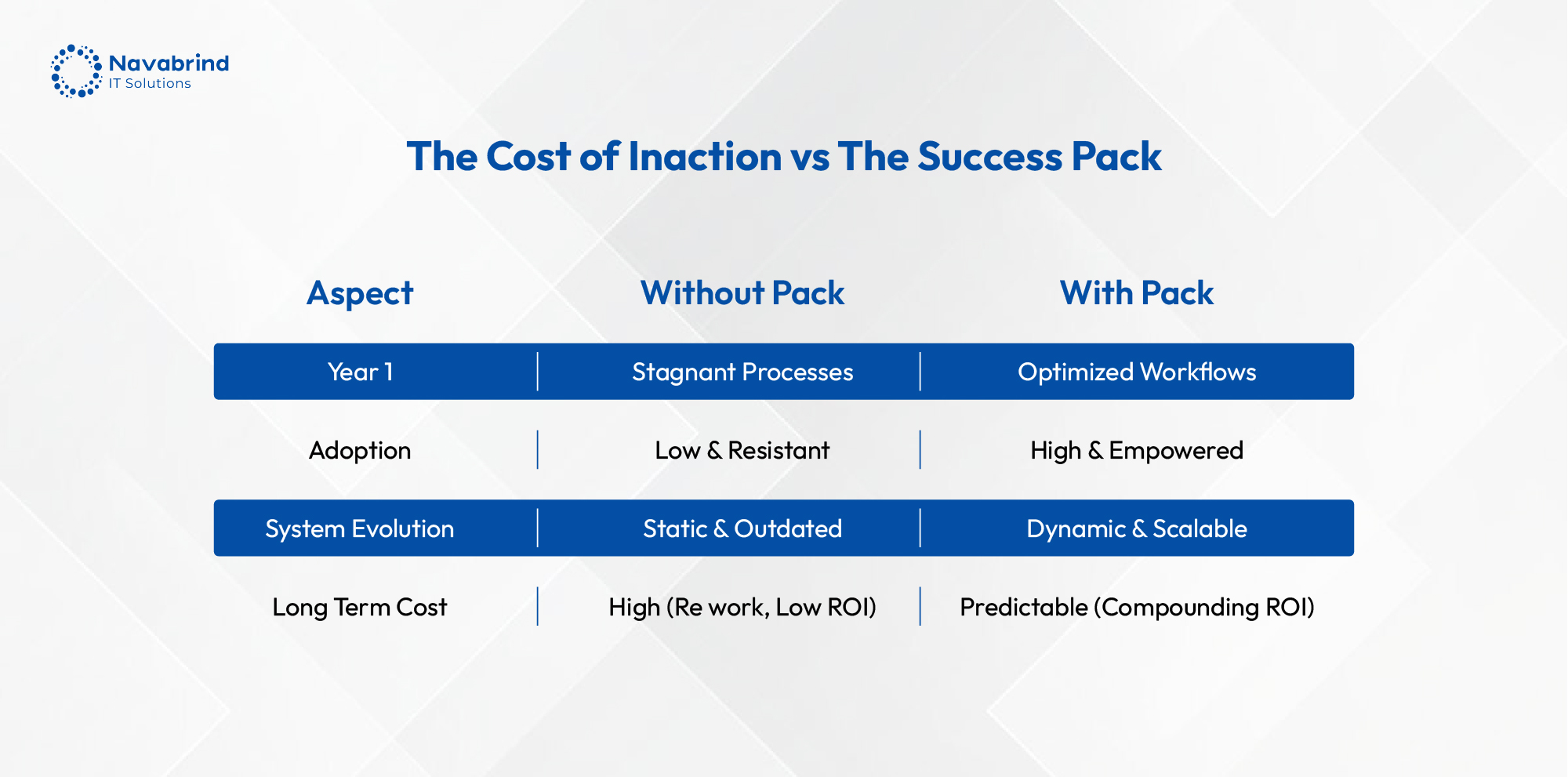

Beyond Go-Live: How Your Odoo Success Pack Drives Real, Long-Term ROI

Beyond Go-Live: How Your Odoo Success Pack Drives Real, Long-Term ROI February 3, 2026 Posted by: Category: Uncategorized No Comments The Implementation Myth Businesses mistakenly measure ERP success by completing the implementation phase while the actual measure of value is the operational transformation unlocked after go-live. The Odoo Success Pack is the framework engineered to

How can we help you?

Get in touch with a solutions consultant that can share best practices and help solve specific challenges.