How Odoo ERP Drives Efficiency in the Steel Industry

- February 18, 2026

- Posted by: Tony

- Categories: Blog, Odoo

The High-Stakes Race of Auto Parts Manufacturing

Your OEM demands a production schedule shift, but procurement can’t confirm steel availability. The sales team lacks real-time inventory data for a quote and your shop floor operates on yesterday’s information. This reality defines most steel and auto parts manufacturing companies. Disconnected systems create costly delays and missed opportunities. This is where an Odoo ERP steel industry solution becomes important. Navabrind IT Solutions provides an integrated platform that turns data into action, transforming friction into a competitive advantage.

Why Odoo ERP Drives Steel and Auto Parts Manufacturing

Master complex steel industry supply chains and volatile demand. Discover how the Odoo manufacturing module for steel, integrated Odoo inventory management, and Odoo quality control to create an integrated ERP steel supply chain. Unlock the main benefits of ERP in steel production, enhanced ERP production planning, Odoo cost savings, and an ERP for the metal industry. Transform operations with steel ERP software.

The Odoo ERP steel industry solution delivers an integrated ERP steel supply chain, addressing steel ERP software advantages. Its Odoo manufacturing module for steel optimizes ERP production planning, while Odoo inventory management steel eliminates waste. Odoo quality control ensures compliance, and the platform’s flexibility provides a scalable ERP for the metal industry. This approach unlocks the benefits of ERP in steel production, driving Odoo cost savings and growth for fabricators and auto parts manufacturers.

The High-Stakes Race of Auto Parts Manufacturing

The auto parts manufacturing sector operates under intense, unrelenting pressure. Strict Just-In-Time (JIT) delivery mandates from automakers leave no room for error, while global competition and rising material costs compress margins. The accelerating transition to Electric Vehicles (EVs) disrupts supply chains and demands adaptation to new component specifications.

- Operational Challenges: How does your business manage thousands of SKUs with precision? How do you guarantee complete traceability for warranty claims or safety recalls? Can your production line adapt when an OEM shifts demand or alters a design?

- The Fragmented Reality: Manufacturers are hampered by disconnected systems, spreadsheets, standalone software, and manual processes that create information silos. This fragmentation means procurement lacks real-time visibility into shop floor material usage, sales teams quote based on outdated inventory data, and production schedules are built on assumptions, not facts.

- The Integrated Solution: An Odoo ERP steel industry platform is engineered to be your command center. It creates a smooth, integrated ERP steel supply chain, synchronizing the process from steel procurement to final assembly and delivery. This steel ERP software delivers the benefits of ERP in steel production, absolute control and end-to-end visibility.

- The Functional Advantage: The Odoo manufacturing module for steel enables ERP production planning. Odoo inventory management provides stock accuracy across warehouses, eliminating shortages and excess. Embedded Odoo quality control protocols within the steel ERP enforce standards and component traceability.

- The Strategic Outcome: You implement an ERP for the metal industry designed to grow with your business. This integration drives measurable Odoo cost savings by reducing waste, optimizing labor, and preventing expensive delays. Navabrind IT Solutions specializes in deploying this tailored digital nerve center, transforming complex, disjointed operations into a streamlined and agile enterprise.

The Challenges of the Auto Parts Manufacturing Ecosystem

Success in auto parts manufacturing depends on navigating a complex, tightly interdependent ecosystem of pressures. The most significant challenge is the volatile, multi‑tiered supply chain. Your production line is highly sensitive to fluctuating steel and aluminum prices, and even a minor delay from a sub‑supplier can disrupt your Just‑In‑Time commitments to OEMs.

You also face an inventory labyrinth—excessive capital tied up in raw materials, mislocated work‑in‑progress, and difficulty fulfilling aftermarket orders for legacy parts. This operational friction erodes margins and weakens your competitive agility.

At the same time, you must guarantee precision and full traceability under stringent AS/ISO standards while managing shop‑floor scheduling across mixed production runs. These daily complexities create financial blind spots, making project‑based costing and ASC 606 revenue compliance particularly challenging.

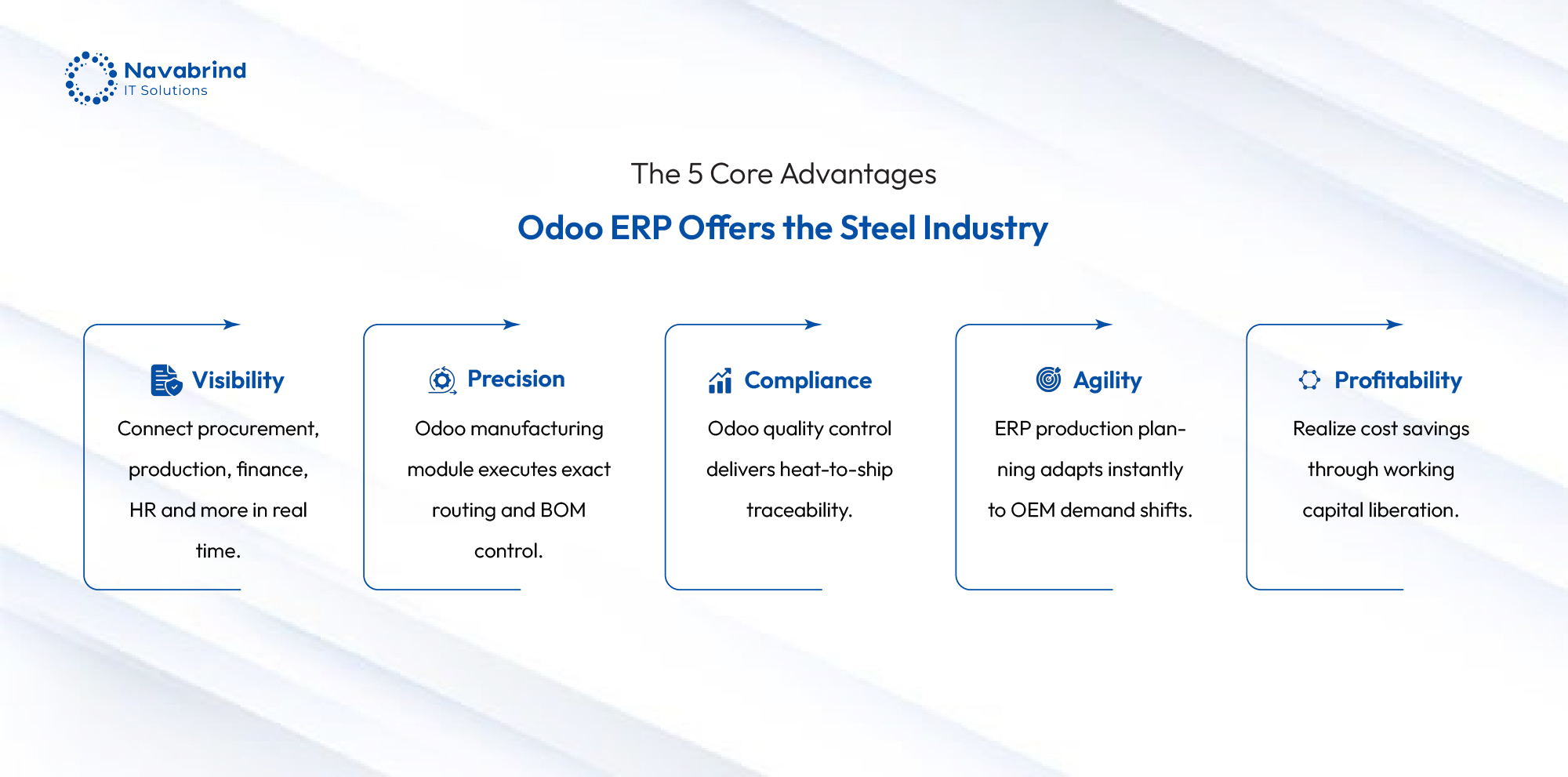

To overcome this, you need more than a collection of disparate tools. You need a unified Odoo ERP platform tailored for the steel and metal industries. This specialized system delivers the core advantages of steel‑focused ERP software, transforming your integrated steel supply chain with Odoo‑driven production planning and quality control.

The result is an ERP for the metal industry that unlocks the full benefits of ERP in steel production—from Odoo‑powered inventory efficiency and manufacturing control to measurable cost savings and plant‑level performance improvements, all managed through the Odoo manufacturing module for steel.

The ERP Advantage: Building Your Digital Nerve Center with Odoo

In a manufacturing environment, Odoo ERP functions as a central platform that transmits signals between procurement, production, sales, and finance, replacing fragmented decision‑making with unified visibility. This integrated ERP in the steel supply chain eliminates information lag and delays. When your shop floor consumes material, Odoo inventory automatically updates procurement. When an OEM order changes, the system reprioritizes work orders in real time.

This synchronization is the defining advantage of steel‑focused ERP software. You gain an ERP foundation for the metal industry that delivers the core benefits of ERP in steel production: speed and control. The Odoo manufacturing module for steel executes this intelligence, while embedded Odoo quality control ensures compliance with industry standards.

This is how you achieve meaningful Odoo cost savings in steel plant operations—not through isolated tools, but through a connected platform that operates as a single, intelligent system.

Core ERP Features That Drive Auto Parts Success

1. Supply Chain & Procurement Agility

Odoo ERP for the steel industry transforms procurement with automated vendor scorecards, tracking on-time delivery, pricing consistency, and defect rates. Material requirement planning runs against live sales orders and accurate forecasts. The purchase order transmits real-time status; the system flags supplier delays before they impact production. This visibility lets buyers intervene early, securing alternative sources or expediting shipments. Procurement transforms from a cost center into a strategic asset, protecting margins and customer commitments.

2. Shop Floor Control & Precision Manufacturing

The Odoo manufacturing module for steel delivers precision across the production floor. Detailed production scheduling optimizes machine utilization and labor allocation. Work orders include routing instructions, accurate bills of materials, and real‑time labor tracking. Machine integration via IoT feeds live OEE (overall equipment effectiveness) data directly into dashboards.

The embedded Odoo quality control steel ERP enforces in‑process checkpoints, automates First Article Inspection documentation, and manages the Non‑Conformance Report lifecycle. Components carry lot and serial traceability throughout the value chain.

This is ERP production planning for steel executed with disciplined rigor, delivering the full benefits of ERP in steel production.

3. Intelligent Inventory & Warehouse Management

Odoo inventory management for the steel industry eliminates guesswork. Real-time stock accuracy spans materials, work-in-progress, finished goods, and aftermarket components across the locations. Barcode and RFID integration eliminates picking and shipping errors. The system applies valuation methods, FIFO, LIFO, or weighted average. Automated reorder points trigger purchase requisitions when stock hits defined thresholds. You never carry excess safety stock or scramble for components.

4. Financial Control & Strategic Insight

Odoo ERP in the steel industry tracks every direct and indirect cost against production runs and customer orders. Revenue recognition complies with ASC 606 standards for complex, multi-deliverable contracts. Customizable executive dashboards present live KPIs, gross margin by product line, on-time delivery percentage, inventory turnover ratios, and plant-wide equipment effectiveness. Leadership makes decisions based on current truth. These are the crucial ERP software advantages that separate market leaders from struggling suppliers.

Implementation of an Odoo ERP for the steel industry requires measurable, predictable financial and operational returns. These are not theoretical benefits, they are outcomes our clients consistently achieve.

30% Reduction in Inventory Carrying Costs

Odoo inventory modules provides real-time visibility across materials, work-in-progress, and finished goods. Automated reorder points and accurate demand forecasting prevent capital-hoarding safety stock. You free working capital tied up in stagnant inventory and redirect it toward growth initiatives.

20% Improvement in On-Time, In-Full Delivery to OEMs

Your integrated ERP for the steel supply chain synchronizes procurement, production scheduling, and shipping. ERP production planning for steel operates against live customer demand. When an OEM accelerates a deadline, the Odoo manufacturing module reprioritizes work orders. Sales confirms delivery dates with confidence. Your OTIF score climbs, securing preferred supplier status and repeat business.

15% Increase in Shop Floor Productivity

Operators spend time fabricating components, not searching for materials or interpreting handwritten traveler sheets. The Odoo manufacturing module for steel delivers work instructions, accurate bill of materials, and real-time labor tracking at the machine. Supervisors monitor OEE through live dashboards, identifying and eliminating micro-stoppages.

Complete Traceability for Recalls

When an OEM issues a recall, you identify affected components in seconds. Odoo quality control enforces lot and serial traceability from steel receipt through final shipment. Every heat number, operator, and inspection checkpoint is recorded. You contain liability exposure, protect your brand reputation, and satisfy customer audit requirements.

Real-Time Financial Visibility

Finance no longer needs to wait until month‑end reconciliations to understand profitability. Odoo ERP for the steel industry integrates job costing directly into production transactions. Every labor hour, kilogram of material, and machine minute is captured and costed in real time. Gross margin by product line, customer profitability, and plant‑wide inventory turnover appear on executive dashboards that update continuously.

This transformation delivers the full benefits of ERP in steel production: improved working capital efficiency, operational excellence, compliance certainty, and strategic agility. You deploy a scalable ERP foundation for the metal industry that drives sustained Odoo‑driven cost savings and enhanced steel plant performance over the long term.

Shift Gears for the Future with Odoo ERP

The benefits of Odoo in steel production extend beyond operational metrics. You gain a scalable ERP architecture for the metal industry that can absorb new product lines, additional facilities, and evolving customer requirements without friction. You realize Odoo‑driven cost savings in steel plant operations through waste elimination, productivity gains, and working capital optimization. These are the steel ERP software advantages that distinguish industry leaders from obsolete suppliers.

Defend outdated methods and accept diminishing margins, eroding market share, and escalating compliance risk. Or seize control with a purpose‑built Odoo ERP solution for the steel industry that transforms complexity into competitive leverage.

Frequently Asked Questions

1. What features does the Odoo manufacturing module for steel include and how does it support Odoo manufacturing execution in steel plants technical use?

The Odoo manufacturing module for steel delivers multi-level BOM, production routing, and real-time work order execution. Odoo manufacturing execution in steel plants captures live labor tracking and IoT machine integration for OEE monitoring. ERP production planning steel synchronizes shop floor operations with procurement and sales. This Odoo ERP for the steel industry creates an integrated ERP steel supply chain. Co-product, by-product, and scrap management handle steel-specific production realities. These ERP software advantages for the still industry define how Odoo ERP improves steel production efficiency across the manufacturing stage.

2. How does Odoo inventory management steel handle heavy materials like coils, sheets, and bars, and how does this demonstrate how Odoo ERP helps reduce inventory cost in steel value proposition?

Odoo inventory management for steel supports multiple units of measure—tons, kilograms, pieces, and linear meters. Lot tracking captures heat numbers and mill certificates, ensuring full traceability. Location‑based inventory tracks material across yards, warehouses, and WIP staging areas, giving you precise visibility at every step.

Barcode and RFID integration streamline receiving and picking, while automated reorder points trigger procurement with precision. This is how Odoo ERP reduces inventory costs in steel operations, delivering measurable Odoo‑driven cost savings and plant‑level outcomes through working capital liberation.

3. Can Odoo quality control steel ERP manage certifications and traceability requirements, and what is the process for how Odoo manages quality compliance in steel compliance?

Odoo’s quality control module for the steel industry enforces in‑process inspection checkpoints at every stage of the production routing. First Article Inspection records are generated automatically and stored permanently, ensuring consistent documentation. Non‑Conformance Reports trigger structured corrective action workflows with complete audit trails, turning quality issues into controlled improvement cycles.

Full lot and serial traceability links finished components backward to raw material certificates and forward to customer shipments, creating an unbroken chain of custody. This is how Odoo manages quality compliance in demanding steel environments. The Odoo ERP platform for the steel industry delivers genealogical traceability in seconds—critical when responding to OEM recall requests with speed, accuracy, and confidence.

4. What measurable Odoo cost savings steel plant operations can I expect, and what Odoo ERP reporting benefits for steel factories analytics validate these outcomes?

Clients achieve 30% inventory carrying cost reduction through Odoo inventory management steel accuracy. Shop floor productivity increases by 15% via ERP production planning steel eliminating idle time. On-time delivery improves by 20% through integrated ERP steel supply chain synchronization. Scrap and rework costs decline with proactive Odoo quality control steel ERP. Odoo ERP reporting benefits for steel factories include real-time gross margin dashboards, inventory turnover analytics, and customer profitability reports. These Odoo cost savings steel plant outcomes are documented examples of Odoo ERP success in steel manufacturing.

5. How does an ERP for the metal industry accommodate growth and changing product mixes, and what do Odoo vs other ERP for steel industry comparisons reveal about platform flexibility?

Odoo ERP for the steel industry is modular. Multi-company, multi-warehouse, and multi-currency operations are native capabilities. Adding production lines or acquiring facilities requires configuration, not reimplementation. Odoo vs other ERP for steel industry comparisons highlight this flexibility. The platform scales from one plant to global enterprise without migrating systems. This makes Odoo the scalable ERP for metal industry choice for growing steel manufacturers.

6. How long does implementation take, what does Navabrind IT Solutions methodology include, and can you share examples of Odoo ERP success in steel manufacturing case study from client deployments?

As an Odoo Gold Partner, Navabrind IT Solutions implements Odoo ERP for the steel industry. The duration of the implementation is determined by the number of modules to be implemented, integrations required, quantity of data to be migrated and several other factors. We begin with a Discovery and Process Mapping the clinents workflows and compliance mandates. Phased Implementation deploys the Odoo manufacturing module, Odoo inventory module, Odoo quality control, and finance modules incrementally. Training and Change Management ensures confident adoption. Ongoing Support provides optimization. Examples of Odoo ERP success in steel manufacturing include achieving 30% inventory reduction and 20% OTIF improvement within six months.

Schedule a conversation with us now!

Related Articles

-

Post

How Odoo ERP Drives Efficiency in the Steel Industry

How Odoo ERP Drives Efficiency in the Steel Industry February 18, 2026 Posted by: Tony Categories: Blog, Odoo No Comments The High-Stakes Race of Auto Parts Manufacturing Your OEM demands a production schedule shift, but procurement can’t confirm steel availability. The sales team lacks real-time inventory data for a quote and your shop floor operates -

Post

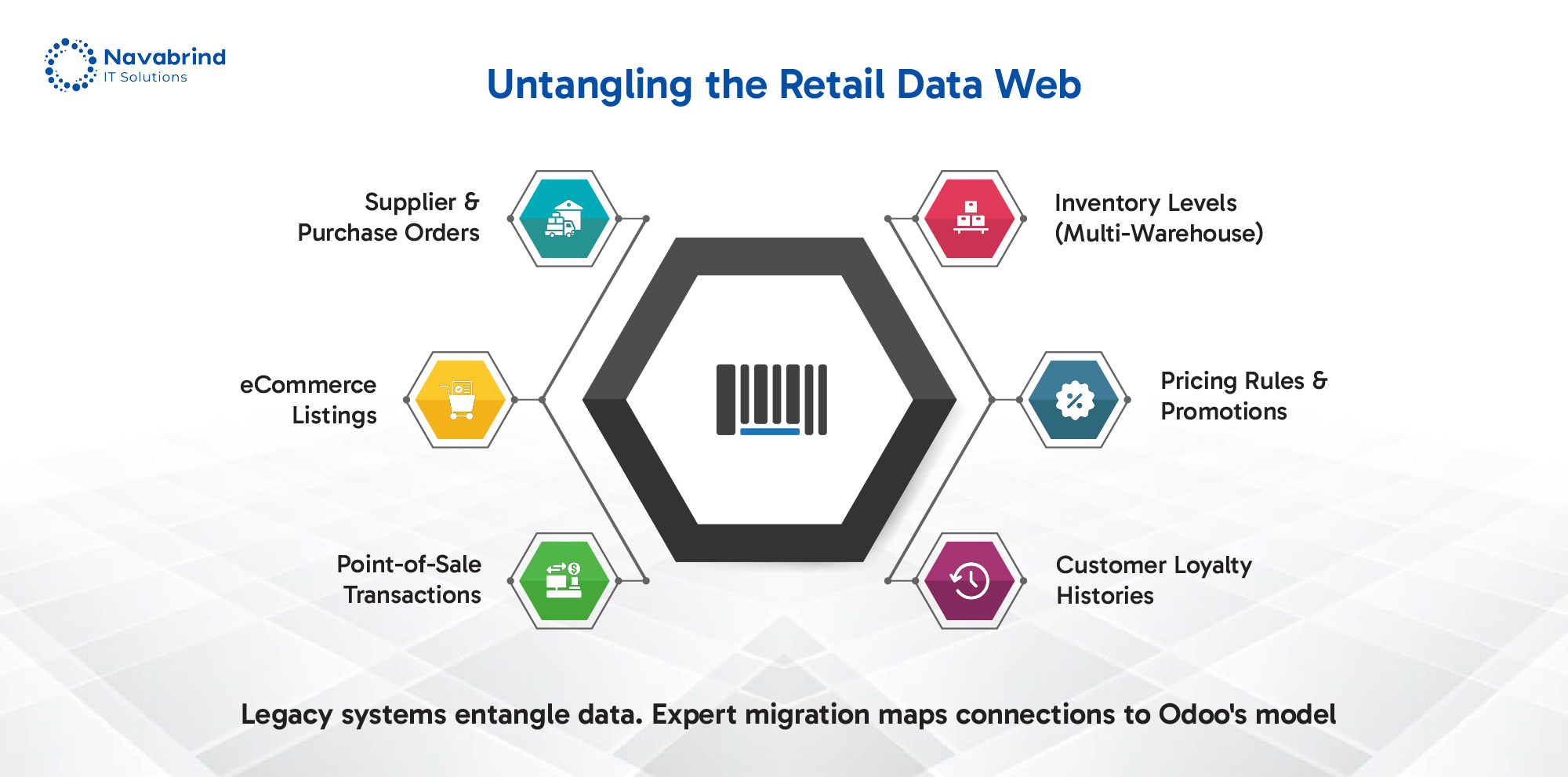

Odoo Database Migration Guide: From Homegrown Retail ERP to Odoo ERP Without Downtime

Odoo Database Migration Guide: From Homegrown Retail ERP to Odoo ERP Without Downtime February 18, 2026 Posted by: Tony Category: Uncategorized No Comments The Need for Smooth Odoo Database Migration If your outdated software, disparate applications, and an unsupported ERP begin to hinder work, you are no longer dealing with a minor technical issue, but -

Post

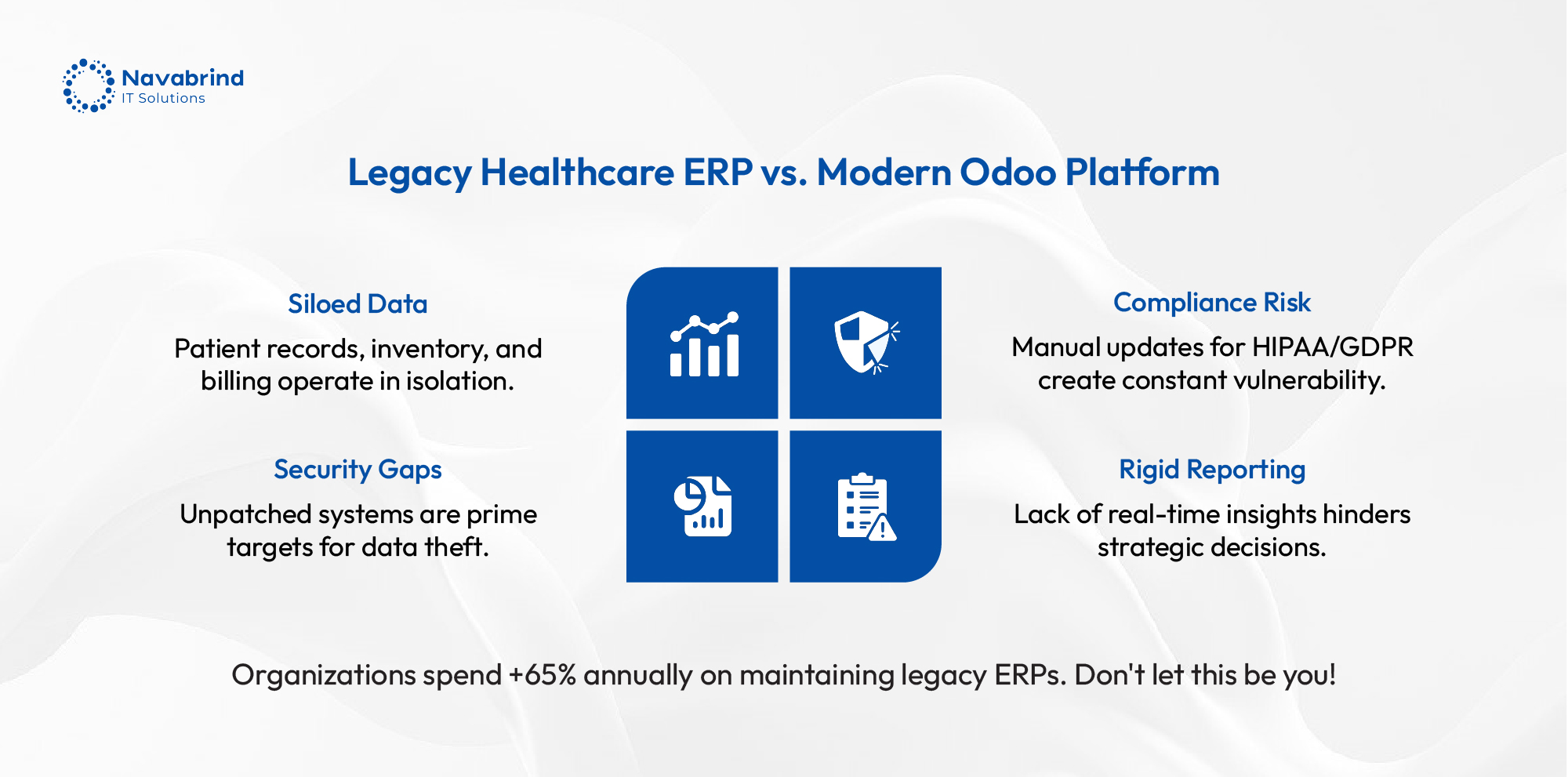

From Legacy Healthcare ERP to Odoo ERP: Why You Need Expert Odoo Migration Help

From Legacy Healthcare ERP to Odoo ERP: Why You Need Expert Odoo Migration Help February 11, 2026 Posted by: Tony Category: Uncategorized No Comments Why Healthcare Organizations Need Odoo ERP Migration Legacy healthcare ERP systems create barriers to efficiency. They are expensive to maintain, and struggle to integrate tools. This disconnect impacts patient care coordination,

How can we help you?

Get in touch with a solutions consultant that can share best practices and help solve specific challenges.