Smart Manufacturing Starts Here: Odoo ERP for Advanced Data Management

- July 2, 2025

- Posted by: Tony

- Categories: Blog, Odoo Manufacturing

Manufacturing companies face mounting pressure to digitalize operations, yet 70% of digital transformation initiatives fail to reach their goals. Smart factories promise enhanced efficiency and productivity, however, many organizations struggle to find the right technology foundation to build upon. In this scenario, Odoo ERP for manufacturing emerges as a crucial offering for companies pursuing smart factory success. This comprehensive ERP system specifically addresses the complex demands of manufacturers in an Industry 4.0 setting, providing real-time visibility, automated workflows, and data-driven insights that modern manufacturing requires.

The Smart Factory and Manufacturing Challenges

The manufacturing sector stands at a pivotal point where 84% of manufacturers are actively using or evaluating smart manufacturing with ERP technology. This surge in digital adoption reflects a fundamental shift, as a majority of manufacturers in 2025 have embarked on their digital transformation journey.

Current state of smart manufacturing with ERP

Manufacturing facilities are rapidly evolving into interconnected hubs where advanced automation technologies and Internet-connected systems drive operations. Notably, technology investments now account for 30% of manufacturing operating budgets in 2024, up from 23% in 2023. The focus has shifted primarily toward cloud solutions, generative AI, and 5G technologies, which deliver the highest return on investment.

Why traditional ERPs fall short compared to Odoo ERP for manufacturing

Traditional on-prem Enterprise Resource Planning systems, once the backbone of manufacturing operations, now struggle to meet modern smart factory demands. These legacy systems suffer from monolithic architectures that resist modification. Consequently, they create data disconnects, leading to partial visibility that impedes collaboration and strategic planning.

Traditional ERPs also face significant limitations in data processing capabilities and real-time analytics. Their rigid structures make it challenging to integrate with emerging technologies like IoT devices and AI systems. These systems rely heavily on manual interventions for routine tasks such as purchase order management and supplier document confirmation, making them inefficient for modern manufacturing needs.

The manufacturing landscape demands greater agility and integration capabilities that legacy ERPs cannot provide. Their inability to support real-time decision-making and predictive insights limits an organization’s ability to mitigate risks proactively. This gap between traditional ERP capabilities and modern manufacturing requirements underscores the need for more advanced solutions.

Odoo ERP for data-driven manufacturing processes

Odoo’s manufacturing module stands out as a powerful solution for modern production facilities, primarily through its ability to provide comprehensive control over manufacturing operations. The system connects every aspect of production, from shop floor activities to enterprise-level planning.

Real-time production visibility and control

Production managers gain instant access to vital manufacturing data through Odoo’s centralized platform. The system tracks work orders in real-time, enabling supervisors to monitor progress and identify bottlenecks instantly. The platform provides detailed insights into material usage, resource allocation, and production timelines.

Production teams benefit from Odoo’s user-friendly interface, which displays real-time updates on work progress and monitors production against deadlines. This visibility extends across multiple locations and companies, making it valuable for large, geographically distributed manufacturing operations.

Automated workflow orchestration

Odoo ERP for manufacturing excels in streamlining manufacturing processes through intelligent automation. The system automatically checks inventory levels in real-time and creates purchase orders when stock falls below required levels. It notifies manufacturing teams to begin production once materials are available, ensuring smooth workflow progression.

Quality management integrates with production processes. The platform enables automated quality checks at various stages, with results logged directly in work orders. This integration helps maintain consistent product quality while reducing manual oversight requirements.

Data-driven decision making capabilities

The platform’s robust analytics capabilities transform raw data into actionable insights. Manufacturers can generate customized reports showing metrics such as production efficiency, labor productivity, and material waste. Essentially, these insights enable businesses to make informed decisions based on actual production data rather than guesswork.

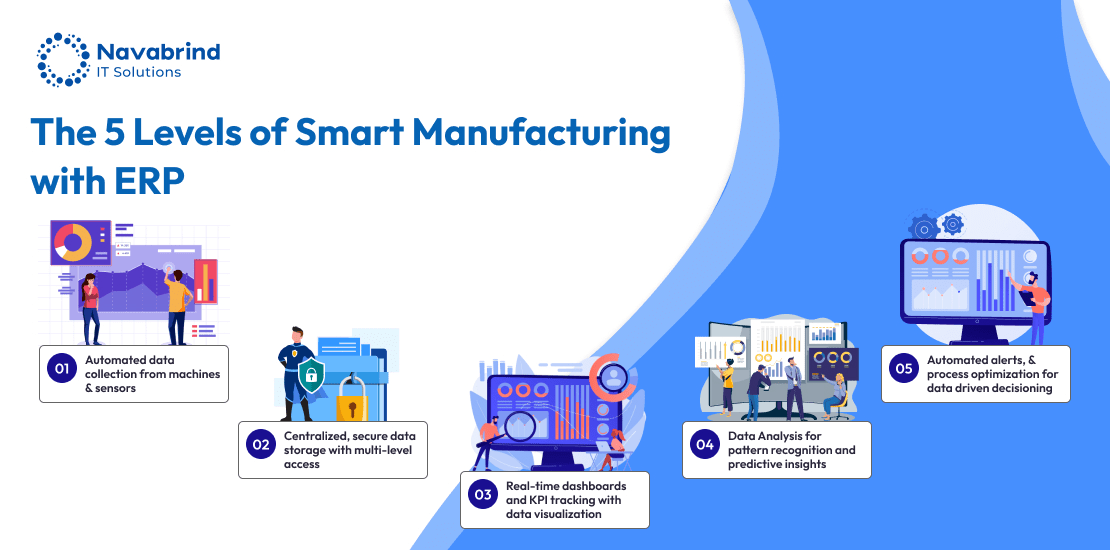

Key analytical capabilities of Odoo ERP data management include:

- Real-time monitoring of key performance indicators

- Detailed reporting on quality metrics and trends

- Production performance analytics

- Resource utilization tracking

- Inventory optimization insights

The system’s data-driven approach ultimately leads to tangible improvements in manufacturing operations. For instance, manufacturers using Odoo’s analytics tools have reported significant enhancements in production efficiency, with some achieving up to 20% improvement in overall production output.

Odoo ERP for Industry 4.0: Manufacturing Excellence Guaranteed

Quality control stands at the heart of manufacturing excellence, with Odoo’s comprehensive quality management system transforming how manufacturers ensure product consistency and compliance.

Quality management and traceability

Odoo’s Quality Control Management module enables manufacturers to implement robust quality checks through strategically placed control points across the supply chain. The system supports multiple quality control plans that trigger checks at critical stages:

- Receiving inspection checkpoints

- In-process quality control operations

- Final quality control inspection

- Statistical process control parameters

- Production part approval processes

The platform’s traceability features assign unique identifiers to each batch or item, enabling precise tracking throughout the manufacturing process. Indeed, this end-to-end visibility helps manufacturers quickly identify and trace affected product batches, ensuring swift recall management while maintaining regulatory compliance.

Resource optimization and scheduling

Odoo’s Work Centers feature primarily focuses on centralizing operations management, offering a clear view of every production stage. The system’s scheduling capabilities ensure optimal resource allocation, accordingly preventing overlaps and adapting production to market demands.

Resource optimization extends beyond machinery to encompass workforce management. The platform enables systematic organization of production activities, undoubtedly improving facility utilization and reducing waste of materials and time. This leads to enhanced operational efficiency and reduced production costs.

Predictive maintenance and downtime reduction

The predictive maintenance capabilities in Odoo represent a significant advancement in equipment management. The system monitors patterns like vibration, temperature, and usage data to forecast potential equipment failures before they occur . This proactive approach helps manufacturing facilities reduce unplanned downtime and extend machinery lifespan.

Real-time monitoring through Odoo’s maintenance module enables quick identification of anomalies. Nevertheless, when the system detects deviations from normal operating conditions, it automatically generates alerts and work orders]. The maintenance calendar helps schedule activities efficiently, ensuring that maintenance is performed only when necessary, thus minimizing unnecessary downtime.

The integration between maintenance and other Odoo modules creates a holistic approach to equipment management. This interconnected system ensures maintenance activities align with production schedules and inventory availability]. Furthermore, the platform’s detailed reporting tools provide insights into equipment performance, enabling data-driven decisions about maintenance scheduling and resource allocation.

Smart Factory Integration and Connectivity

Connectivity forms the foundation of modern manufacturing operations, with Odoo’s smart factory integration capabilities bridging the gap between physical equipment and digital systems. The platform’s advanced connectivity features enable manufacturers to create truly connected production environments.

IoT device integration and management

Odoo’s IoT Box serves as a central hub for connecting manufacturing equipment and devices. This dedicated hardware solution enables real-time data collection from machines and production equipment, primarily focusing on critical parameters like uptime, downtime, and energy consumption. The system’s flexibility allows integration with various IoT-enabled devices, simultaneously monitoring multiple aspects of production operations.

Throughout the manufacturing process, IoT sensors track essential metrics:

- Machine performance and operational status

- Environmental conditions affecting production

- Energy consumption patterns

- Quality control parameters

- Inventory movement and storage conditions

Shop floor to top floor visibility

The Shop Floor module in Odoo ERP for manufacturing enhances production visibility. Unlike traditional systems, this module provides a comprehensive view of all manufacturing operations, enabling supervisors to track work orders and employee assignments in real-time. In fact, the system allows managers to add work centers and operators directly through the dashboard, streamlining operational control].

The platform’s shop floor interface delivers immediate insights into production status, enabling quick identification of bottlenecks and efficiency gaps. Since the system updates continuously, production managers can make informed decisions based on current operational data, ensuring optimal resource utilization and workflow management.

Real-time data synchronization

Odoo ERP for manufacturing has real-time data synchronization capabilities to create a unified information flow across the manufacturing environment. The system automatically updates inventory levels when raw materials are consumed in production, ensuring accurate stock management without manual intervention. This synchronization extends to all aspects of manufacturing operations, from production planning to quality control.

Odoo ERP data management framework supports:

- Immediate analytics for production efficiency improvements

- Automated inventory updates based on real-time consumption

- Communication between departments

- Integration with third-party systems through APIs

The integration framework primarily focuses on reducing manual data entry and ensuring consistent information across all manufacturing modules. Production managers gain access to live insights into line performance, enabling swift identification and resolution of operational inefficiencies]. This comprehensive approach to data synchronization ensures that all stakeholders, from shop floor operators to top management, have access to the same accurate, up-to-date information.

Measuring Smart Factory Success with Odoo

Success in Odoo ERP for Industry 4.0 hinges on measuring and analyzing the right metrics. Odoo’s comprehensive analytics capabilities enable manufacturers to track, measure, and optimize their operations through data-driven insights.

Key performance indicators and metrics

Operational KPIs form the backbone of manufacturing performance measurement in Odoo. The platform tracks vital metrics including:

- Production efficiency rates and cycle times

- Inventory turnover ratios and stock accuracy

- Equipment effectiveness and utilization rates

- Quality control metrics and defect rates

- Resource allocation and workforce productivity

Primarily focusing on user engagement, Odoo monitors adoption rates and training progress to ensure maximum system utilization. The platform’s customizable dashboards allow manufacturers to visualize these metrics in real-time, enabling quick identification of improvement opportunities.

ROI and business impact analysis

Calculating return on investment requires analyzing both initial implementation costs and long-term benefits. Odoo ERP for manufacturing offers significant operational improvements, including a 30% reduction in production time during the first year of implementation. Similarly, businesses achieve 15-20% cost savings in inventory management through automated stock replenishment and optimized warehouse operations.

The financial impact extends beyond direct cost savings. Odoo ERP data management enables manufacturers to track profit margins, revenue growth, and cost reductions across all operations. Therefore, businesses can make informed decisions about resource allocation and process improvements based on concrete financial data.

Continuous improvement framework

Odoo’s data-driven excellence framework supports ongoing optimization through systematic analysis and implementation of improvements. First, the platform enables manufacturers to establish baseline performance metrics. Second, it identifies areas for improvement through trend analysis and pattern recognition. Third, it facilitates the implementation of corrective actions through automated workflows and process adjustments.

The framework’s success relies on robust data governance and standardization protocols [18]. In addition to maintaining data quality, Odoo supports comprehensive role-based access controls, ensuring that sensitive information remains secure while still accessible to authorized personnel [18].

Data cleansing and standardization processes play a vital role in maintaining accurate metrics [18]. Although this requires initial setup effort, the resulting data reliability enables manufacturers to make confident decisions based on trustworthy insights. The platform’s analytical infrastructure supports both predictive and prescriptive analytics, ultimately enabling organizations to transition from reactive to proactive decision-making.

Through continuous monitoring and optimization, manufacturers can identify inefficiencies across production, inventory, and maintenance operations. The system’s predictive capabilities allow businesses to anticipate and address potential issues before they impact production. As a result, manufacturers maintain optimal performance levels while continuously adapting to changing market conditions and operational requirements.

Frequently Asked Questions

1. How Odoo ERP data management enhance manufacturing?

Odoo ERP data management plays a pivotal role in Smart manufacturing with ERP by centralizing and streamlining data management processes. It collects, organizes, and synchronizes data across various manufacturing operations, enabling real-time insights and improved decision-making.

- Centralized Data Hub: Odoo ERP acts as a single platform for managing production, inventory, quality control, and maintenance data, reducing silos and ensuring consistency.

- Real-Time Insights: With live dashboards and reports, manufacturers gain instant visibility into production metrics, inventory levels, and operational bottlenecks, driving data-driven manufacturing processes.

- Automation and Accuracy: Odoo ERP eliminates manual data entry, reducing errors and ensuring that data is accurate and up-to-date across all functions.

- Enhanced Collaboration: By integrating departments like procurement, production, and logistics, Odoo ERP fosters better communication and coordination, leading to streamlined workflows.

For those searching to answer the question, how Odoo ERP enhances manufacturing data management the above capabilities make Odoo ERP for manufacturing an indispensable tool for companies embracing smart manufacturing with ERP solutions.

2. What are the key features of smart manufacturing with ERP?

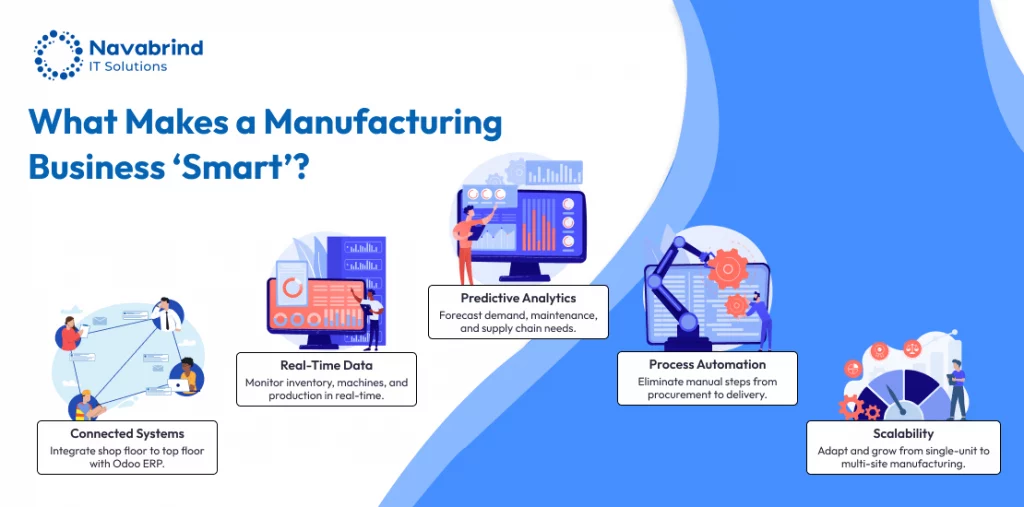

Odoo ERP offers a suite of features tailored to the needs of smart manufacturing with ERP, ensuring efficiency, scalability, and innovation.

- Manufacturing Module: A comprehensive tool for managing production orders, work centers, and bill of materials (BOMs), optimizing production planning and execution.

- Inventory Management: Real-time inventory tracking ensures materials are available when needed, reducing delays and waste.

- Quality Control: Odoo ERP enables manufacturers to set up quality checks at critical production stages, ensuring high product standards.

- Data Analytics and Reporting: The platform provides advanced analytics to monitor KPIs, forecast demand, and track operational performance.

- IoT Integration: Odoo ERP for Industry 4.0 supports IoT devices, enabling automated data collection and machine monitoring to enhance productivity.

- Scalability: Its modular structure allows businesses to scale operations by adding features like PLM (Product Lifecycle Management) and maintenance tracking as needed.

These features make Odoo ERP for manufacturing a comprehensive solution.

3. How can Odoo ERP help manufacturers optimize their production processes?

Smart manufacturing with ERP enhances production processes by streamlining workflows, reducing waste, and improving overall efficiency.

- Production Scheduling: Odoo ERP enables precise scheduling of production tasks, ensuring optimal use of resources and minimizing downtime.

- Demand Forecasting: With historical data and advanced analytics, manufacturers can predict demand more accurately, aligning production schedules with market needs.

- Odoo ERP Data Management: Centralized data allows real-time tracking of raw materials, work orders, and finished goods, improving visibility and control over production.

- Process Automation: Odoo ERP automates repetitive tasks like work order creation, material requisition, and reporting, reducing manual effort and human error.

- Lean Manufacturing Support: The system supports lean manufacturing principles by identifying bottlenecks, tracking wastage, and promoting just-in-time inventory practices.

Implementing Odoo ERP for smart manufacturing with ERP solutions reduces costs, increases efficiency and results in productivity gains

4. How Odoo ERP enhances manufacturing data management

Real-time Odoo ERP data management is crucial for smart manufacturing because it ensures that decisions are based on accurate and up-to-date information.

- Proactive Decision-Making: Odoo ERP provides live updates on production metrics, allowing manufacturers to address issues like machine breakdowns or material shortages immediately.

- Odoo ERP Data Management: By consolidating data from IoT devices, production systems, and other tools, Odoo ERP ensures that stakeholders have a unified view of operations.

- Enhanced Productivity: Real-time insights into work order progress and inventory levels help optimize resource allocation, reducing downtime and inefficiencies.

- Improved Quality Control: Live tracking of quality metrics enables manufacturers to identify and resolve defects early in the production process, minimizing waste and rework.

- Data-Driven Manufacturing Processes: With real-time analytics, manufacturers can identify trends, forecast demand, and make strategic decisions faster.

Odoo ERP for Industry 4.0 empowers businesses to stay agile and competitive in a rapidly evolving landscape.

5. How does Odoo ERP integrate with other systems in a smart manufacturing with ERP environment?

Odoo ERP for manufacturing integrates with various systems and tools, creating a connected ecosystem for smart manufacturing with ERP.

- IoT Integration: Odoo ERP for Industry 4.0 connects with IoT devices to collect real-time machine data, monitor performance, and automate workflows.

- Third-Party Applications: Odoo integrates with tools like CAD software, PLM systems, and CRM platforms, ensuring a unified flow of information across all functions.

- API and Webhooks: Odoo ERP offers robust APIs and webhook support for custom integrations with niche software or legacy systems used in manufacturing environments.

- Shop Floor Automation: The platform integrates with shop floor devices like barcode scanners, conveyors, and automated storage systems to enhance operational efficiency.

- Cloud and On-Premise Deployment: Odoo’s flexibility allows businesses to deploy it alongside existing systems, whether in the cloud or on-premise, ensuring compatibility with their IT infrastructure.

By integrating with other systems, Odoo ERP enables manufacturers to implement smart manufacturing with ERP solutions that are interconnected and efficient.

6. What benefits does Odoo ERP offer for managing data in Industry 4.0?

Odoo ERP for manufacturing provides a range of benefits for managing data in the context of Industry 4.0, driving innovation and operational excellence.

- Enhanced Data Accuracy: Odoo ERP for manufacturing eliminates data silos, ensuring that all information is consistent and reliable across departments.

- Smart Manufacturing with ERP: The platform’s advanced analytics and automation features enable businesses to make informed decisions based on real-time data.

- Scalability: As a modular system, Odoo ERP allows businesses to add features and scale operations as they grow, making it ideal for Industry 4.0 adoption.

- Cost Efficiency: By automating workflows and reducing manual intervention, Odoo ERP helps lower operational costs while boosting productivity.

- Real-Time Visibility: Dashboards and reporting tools provide a unified view of operations, enabling manufacturers to respond quickly to market changes or operational issues.

- Customizable Modules: From inventory management to production scheduling, Odoo ERP for Industry 4.0 tailors requirements, ensuring maximum flexibility.

With these benefits, implementing Odoo ERP for manufacturing solutions positions businesses to thrive in the era of Industry 4.0.

Schedule a conversation with us now!

Related Articles

-

Post

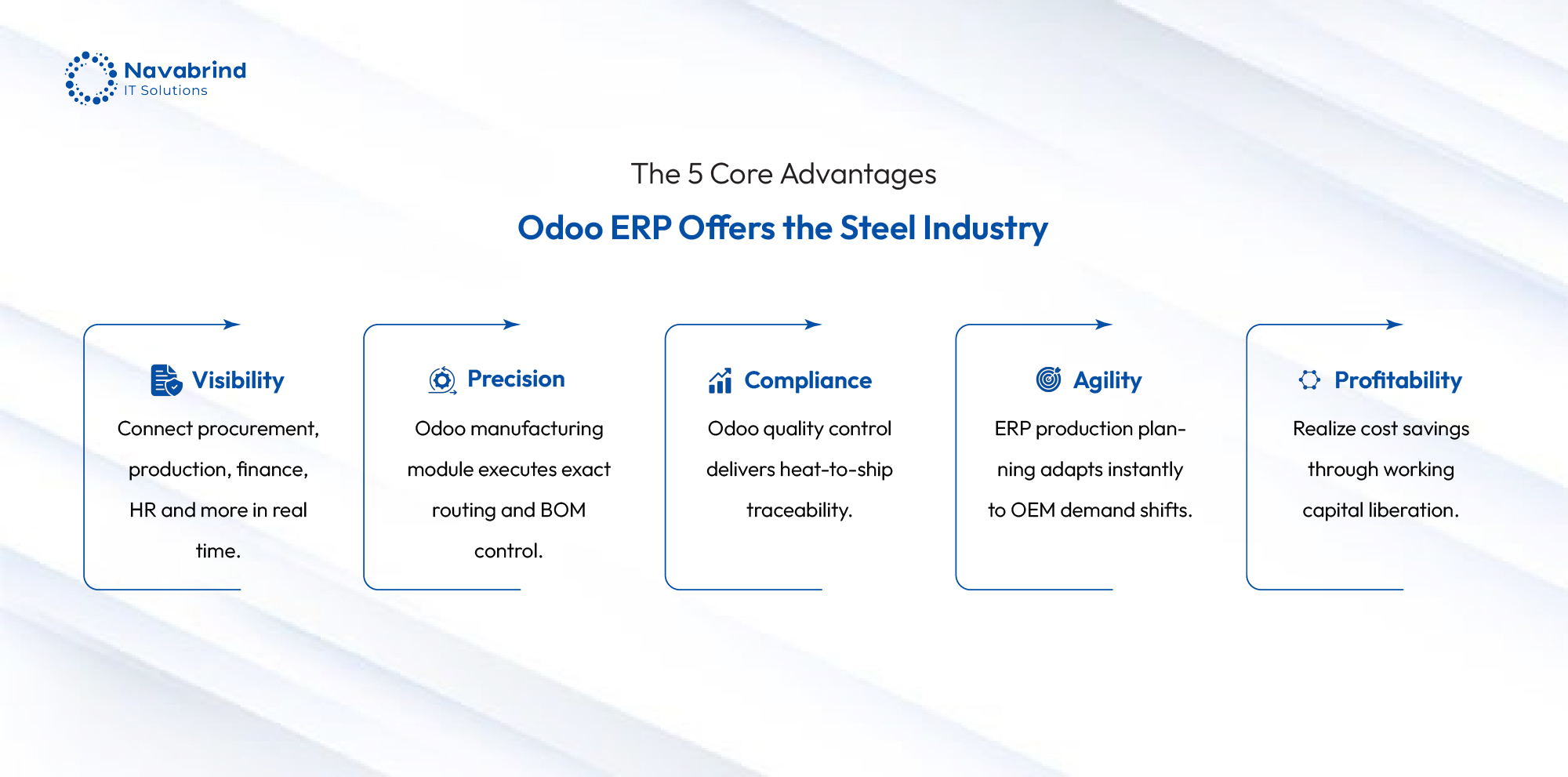

How Odoo ERP Drives Efficiency in the Steel Industry

How Odoo ERP Drives Efficiency in the Steel Industry February 18, 2026 Posted by: Tony Categories: Blog, Odoo No Comments The High-Stakes Race of Auto Parts Manufacturing Your OEM demands a production schedule shift, but procurement can’t confirm steel availability. The sales team lacks real-time inventory data for a quote and your shop floor operates -

Post

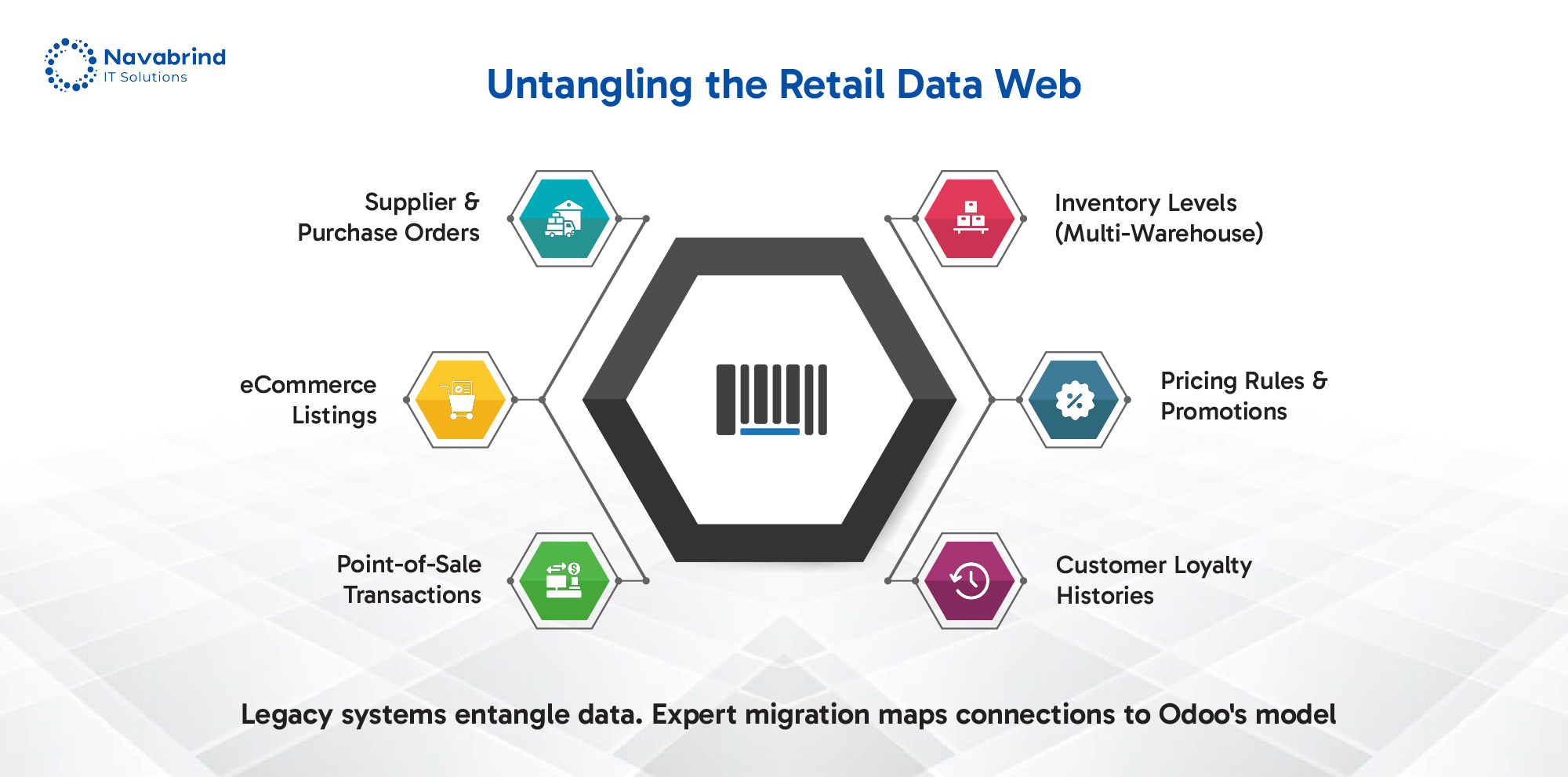

Odoo Database Migration Guide: From Homegrown Retail ERP to Odoo ERP Without Downtime

Odoo Database Migration Guide: From Homegrown Retail ERP to Odoo ERP Without Downtime February 18, 2026 Posted by: Tony Category: Uncategorized No Comments The Need for Smooth Odoo Database Migration If your outdated software, disparate applications, and an unsupported ERP begin to hinder work, you are no longer dealing with a minor technical issue, but -

Post

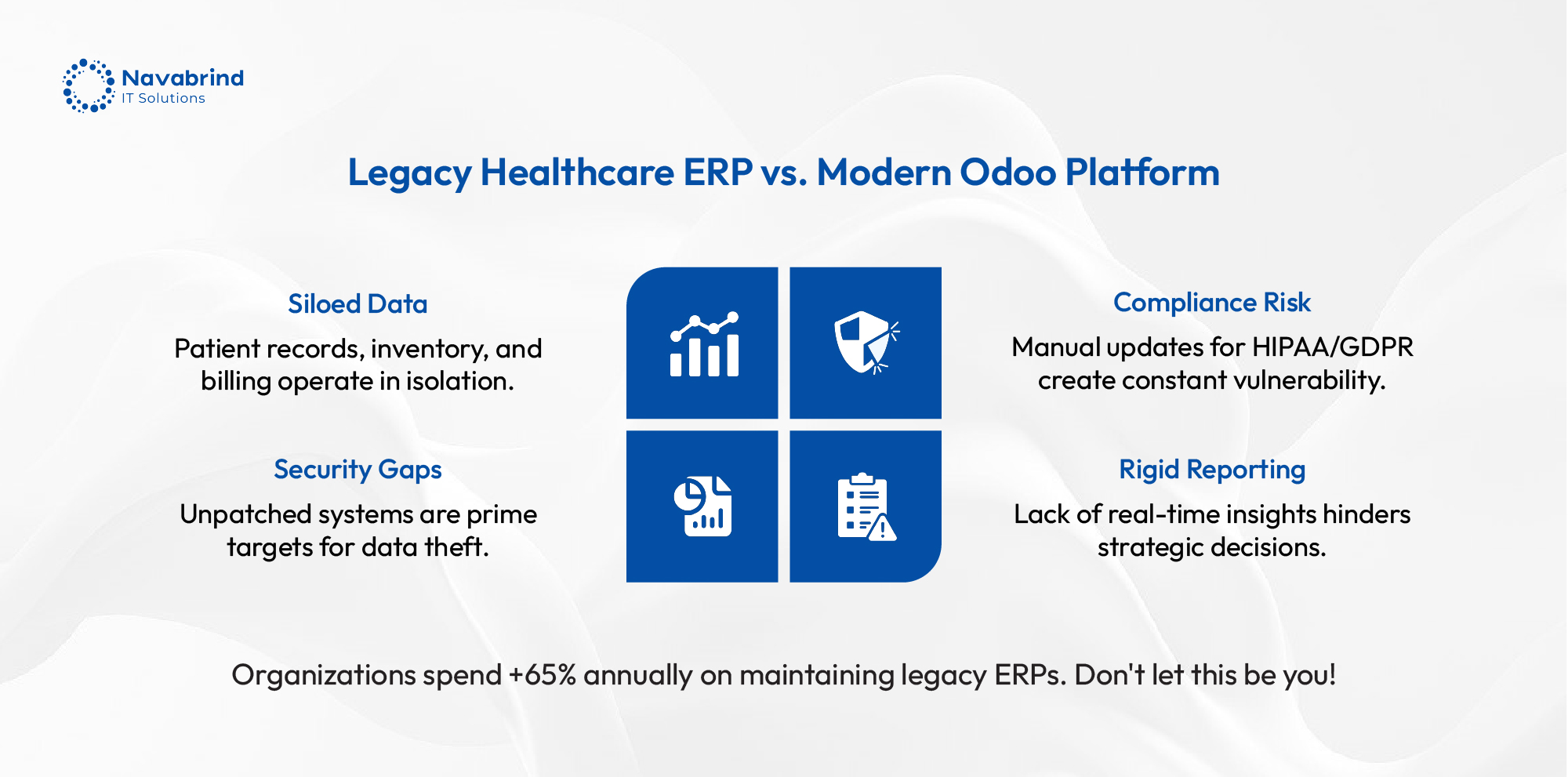

From Legacy Healthcare ERP to Odoo ERP: Why You Need Expert Odoo Migration Help

From Legacy Healthcare ERP to Odoo ERP: Why You Need Expert Odoo Migration Help February 11, 2026 Posted by: Tony Category: Uncategorized No Comments Why Healthcare Organizations Need Odoo ERP Migration Legacy healthcare ERP systems create barriers to efficiency. They are expensive to maintain, and struggle to integrate tools. This disconnect impacts patient care coordination,

How can we help you?

Get in touch with a solutions consultant that can share best practices and help solve specific challenges.